Liquid cooling plate radiator

A radiator and liquid cooling plate technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. limited issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to better understand the above-mentioned technical solutions, the exemplary embodiments of the present application will be described in detail below with reference to the accompanying drawings. Obviously, the described embodiments are only part of the embodiments of the present application, rather than all embodiments of the present application. It is understood that the application is not limited by the exemplary embodiments described herein.

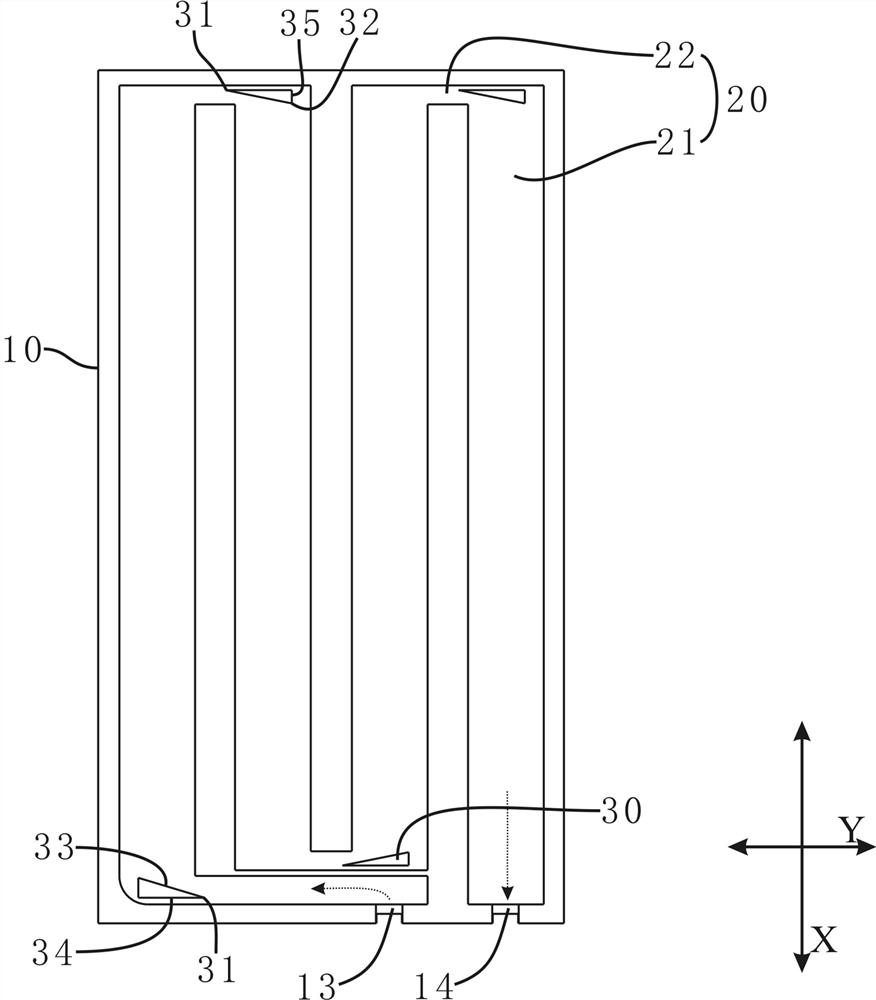

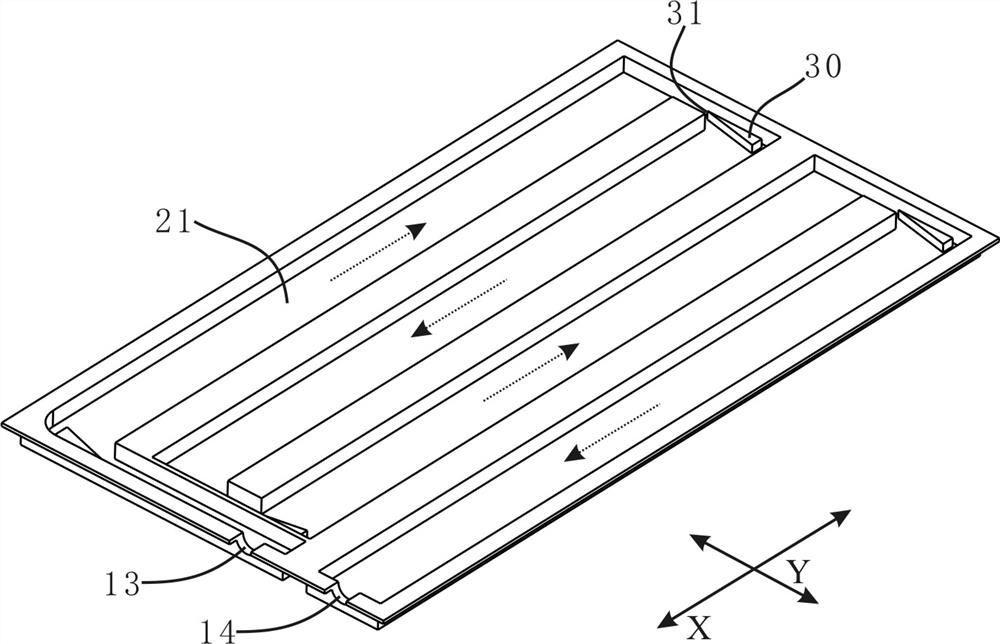

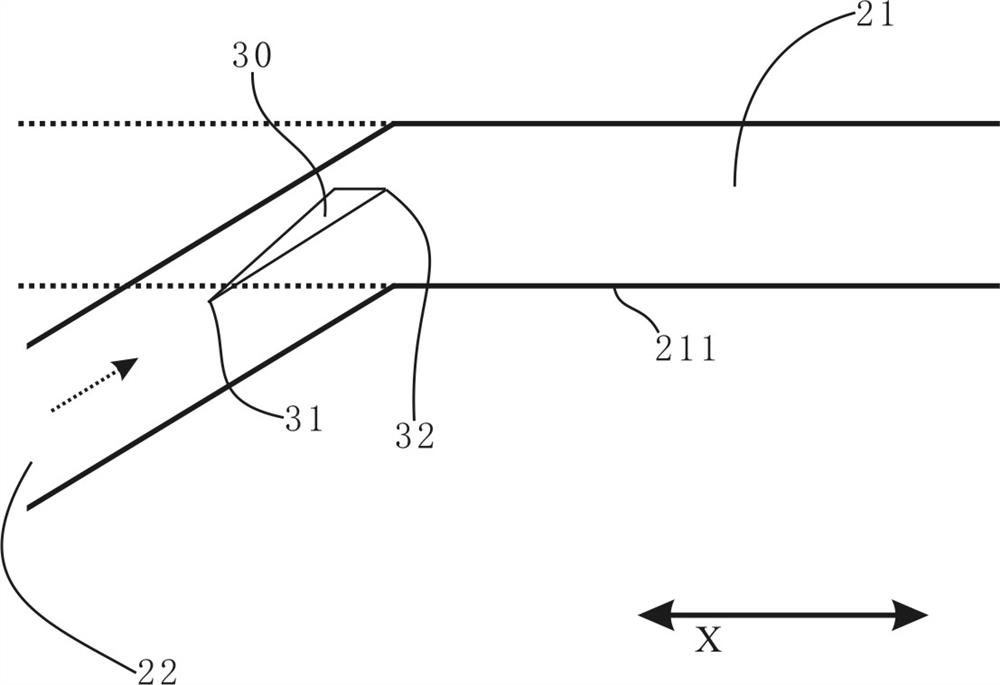

[0066] Please combine first figure 1 as well as Figure 6~Figure 9 , the embodiment of the present application discloses a liquid-cooled plate radiator, the liquid-cooled plate radiator includes a radiator body 10, a cooling liquid flow channel 20 and a fin unit 40; the cooling liquid flow channel 20 is formed on the radiator body 10 Inside, the cooling liquid channel 20 is used for circulating the cooling liquid, and the cooling liquid channel 20 includes a plurality of cooling sub-channels 21; several fin units 40 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com