Intake silencer for acoustic enclosure of compressor unit

A technology of air intake muffler and sound insulation cover, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., to achieve the effect of improving noise reduction effect, excellent sound absorption and sound insulation performance, and enhancing convective heat transfer intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

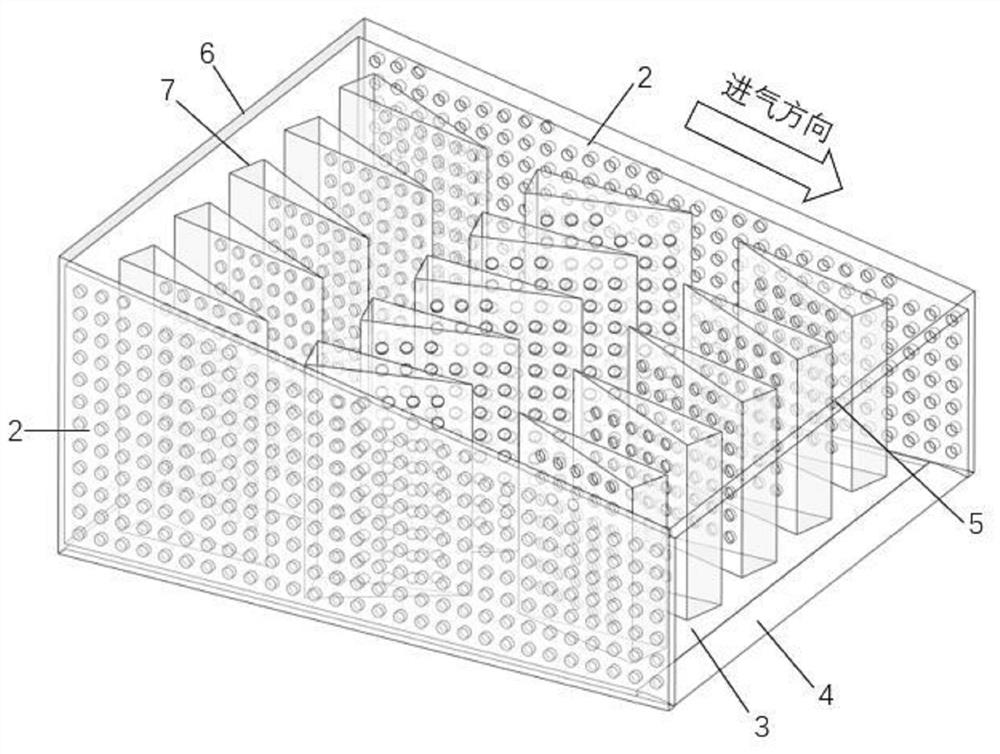

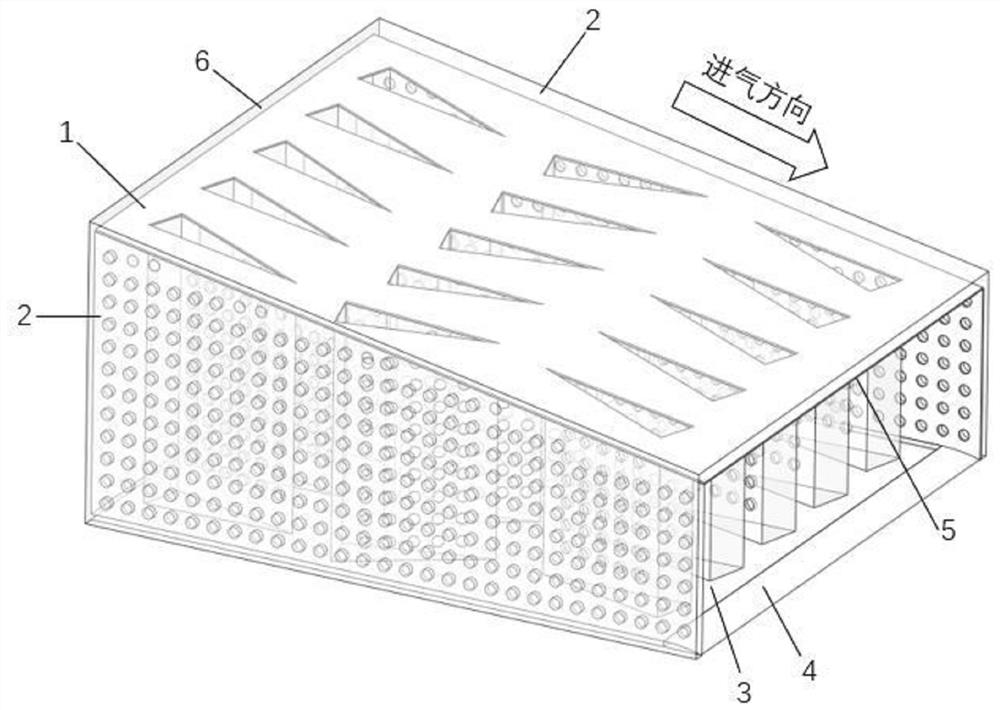

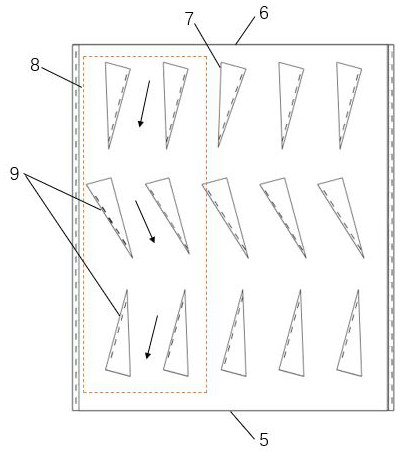

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention relates to an intake muffler for a sound insulation cover of a compressor unit, which is mainly composed of an intake muffler box 1, a broken line type intake muffler channel 8 and a right-angled triangular prism sound-absorbing structure 7; the right-angled The triangular prism sound-absorbing structure 7 is distributed and arranged in the form of a broken line in the air intake direction to form a broken-line intake muffler channel 8; the intake muffler box 1 and the right-angled triangular prism sound-absorbing structure 7 are integrally structured; the right-angled Triangular prism sound-absorbing structure 7 is composed of right-angled triangular prism sound-absorbing structure slope 10 , right-angled triangular prism sound-absorbing structure long right-angled surface 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com