Turbulent flow threaded hole cooling structure for trailing edge of turbine blade and turbine blade

A technology for turbine blades and cooling structures, applied in the direction of blade support elements, machines/engines, mechanical equipment, etc., can solve the problems of insufficient cooling, ignoring the cooling of the surface of the partition rib, and low cooling efficiency of the surface of the partition rib, etc., to achieve good processing Integral, improved overall cooling effect, good heat transfer and cooling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment is a specific implementation case of the cooling structure with spoiler threaded holes on the trailing edge of the turbine blade.

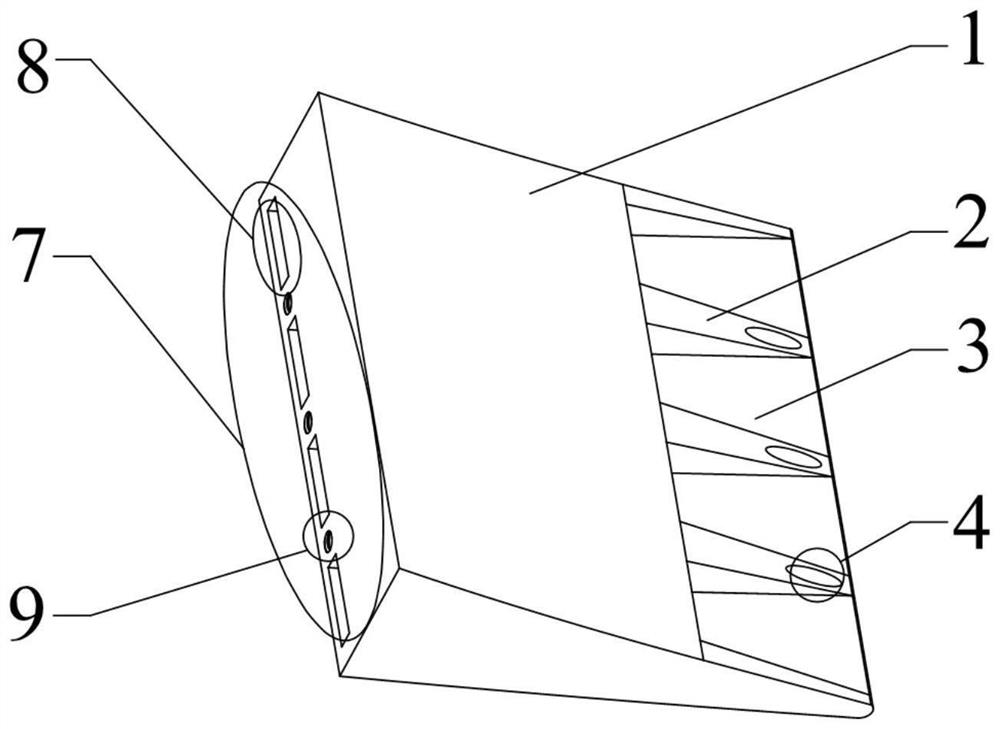

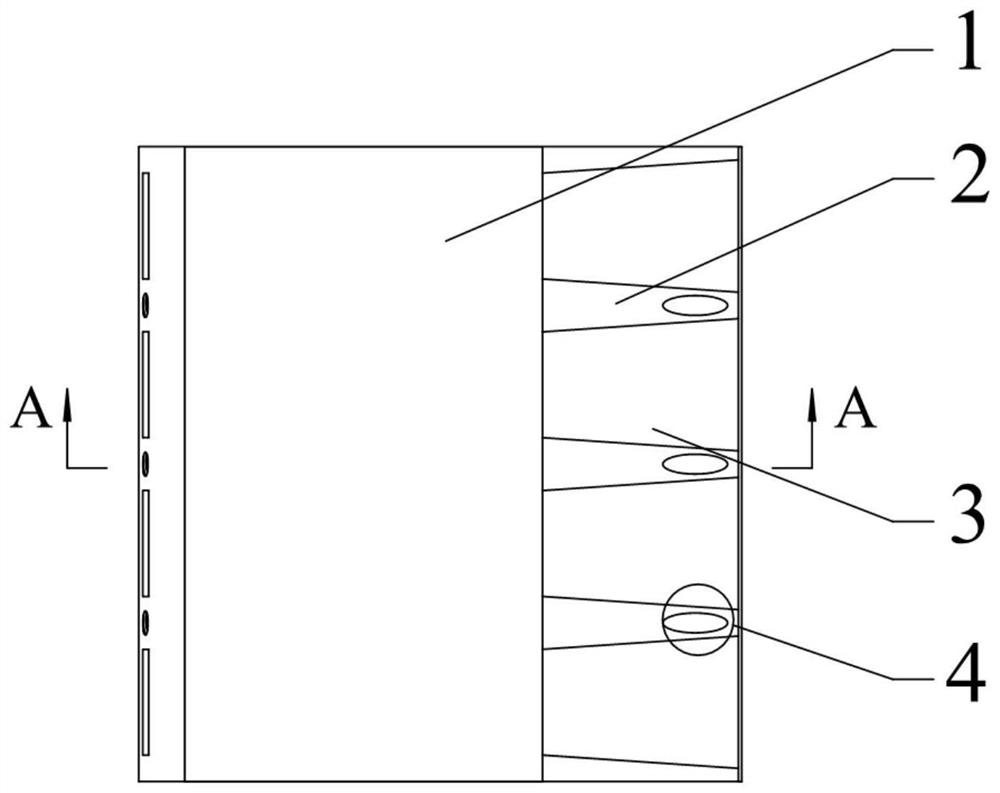

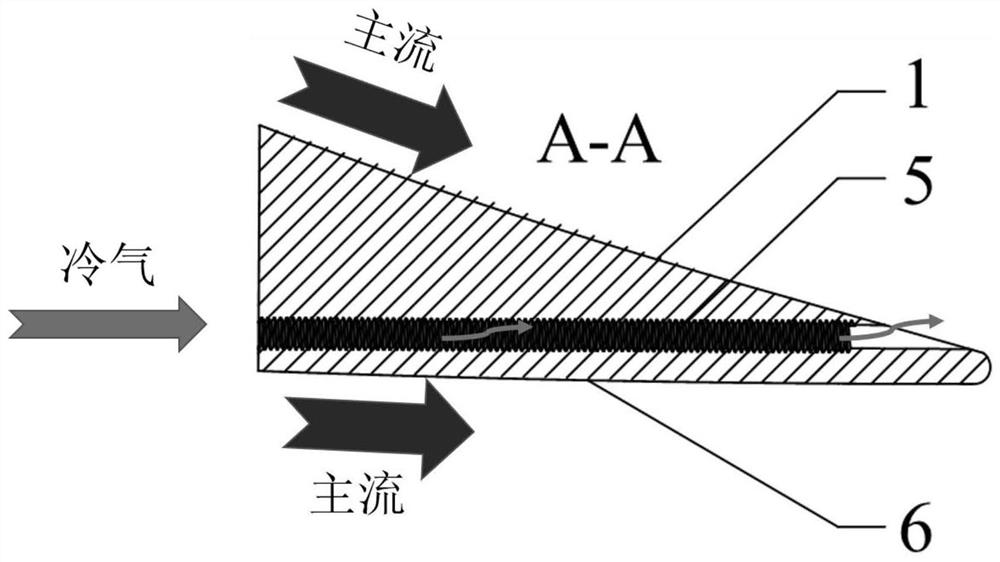

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , this kind of spoiler screw hole cooling structure for the trailing edge of the turbine blade and its application and arrangement position on the turbine blade are introduced in detail.

[0027] This embodiment is a trailing edge cooling structure with spoiler threaded holes on a certain type of turbine working blade. The cooling air flows through the cold flow inlet 7 into the trailing edge cooling structure with spoiler threaded holes. Slit cold air intake cavity 8 and partition rib cooling hole inlet 9 are two inlets of cooling air flow, and the cooling air flow entering the trailing edge cold air intake cavity 8 is sprayed out and covered on the trailing edge half-slit surface 3 to form a cooling air film, thereby cooling The pressure surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com