Circular pipe and flat pipe combined combustion waste heat utilization heat exchange device

A technology of heat exchange devices and flat tubes, which is applied to fixed tubular conduit components, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as poor high temperature resistance, low heat exchange efficiency, and large occupied volume, and achieve Reduce volume and weight, improve heat exchange efficiency, and occupy less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

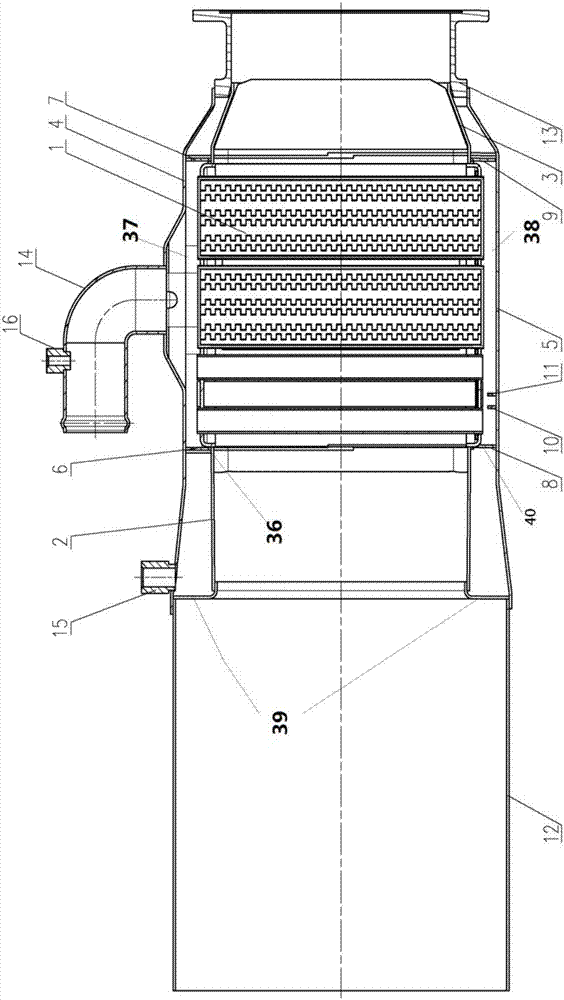

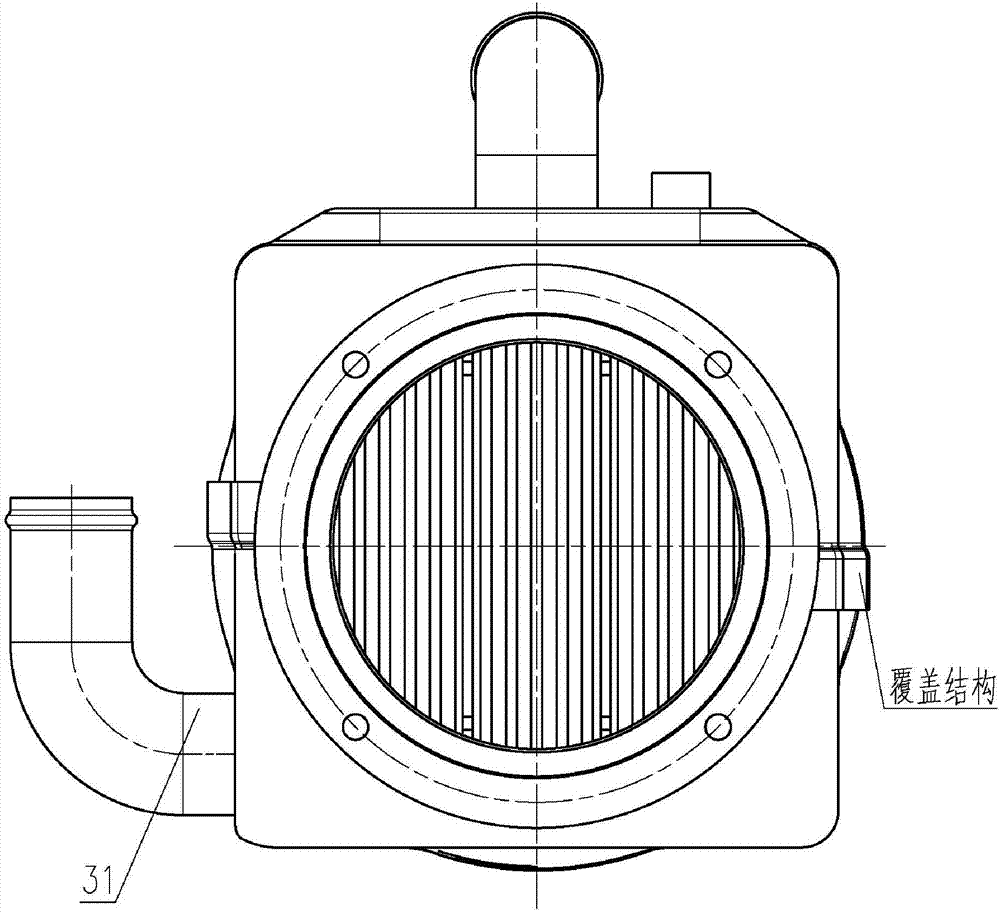

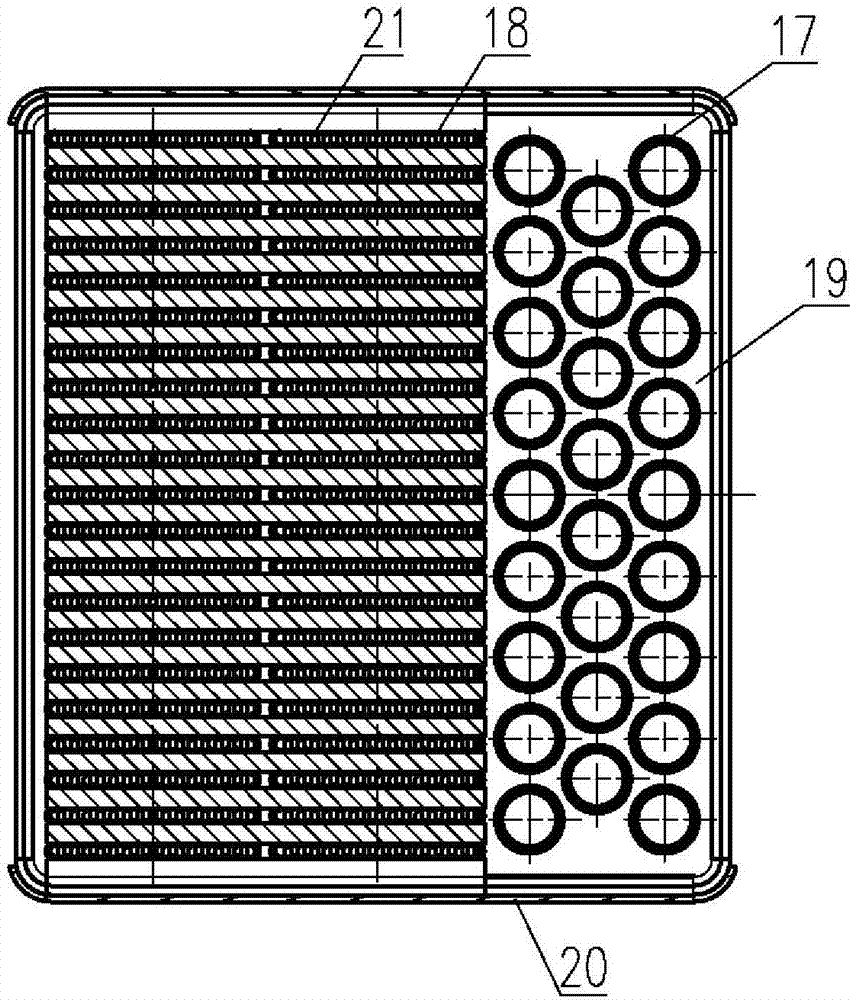

[0051] Such as Figure 1-6 The shown exhaust gas waste heat utilization heat exchange device includes a heat exchange core 1, a front support 2 of the heat exchange core, and a rear support 3 of the heat exchange core. The heat exchange core 1, the front support 2 and the The rear support body 3 is arranged in the exhaust gas flue 12. The heat exchange core 1 includes an upper cover plate 36, a lower cover plate 40 and a plurality of heat exchange tubes, and the heat exchange tubes are connected through the upper cover plate 36 and the lower cover plate 40. , the front support body 2 and the rear support body 3 are respectively located at both ends of the heat exchange core body 1, and together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com