Turbine blade tail edge turbulence half-crack cooling structure with spherical surface convex block

A turbine blade and trailing edge technology, applied in the direction of blade support components, engine components, machines/engines, etc., can solve problems such as tending to the limit, reduce the maximum temperature and average temperature, avoid high temperature ablation, and improve the gas film Effect of convective heat transfer coefficient and heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

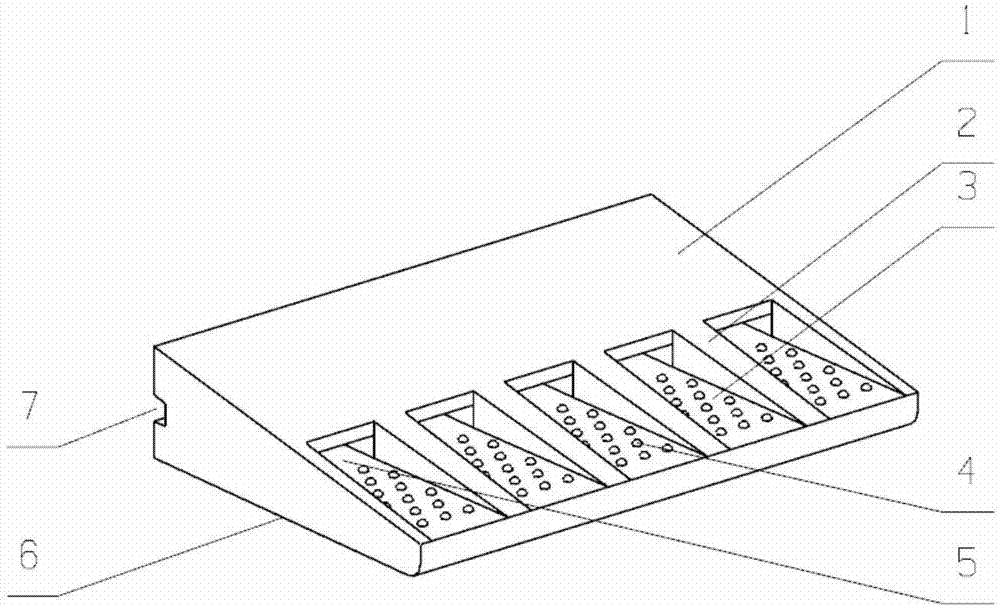

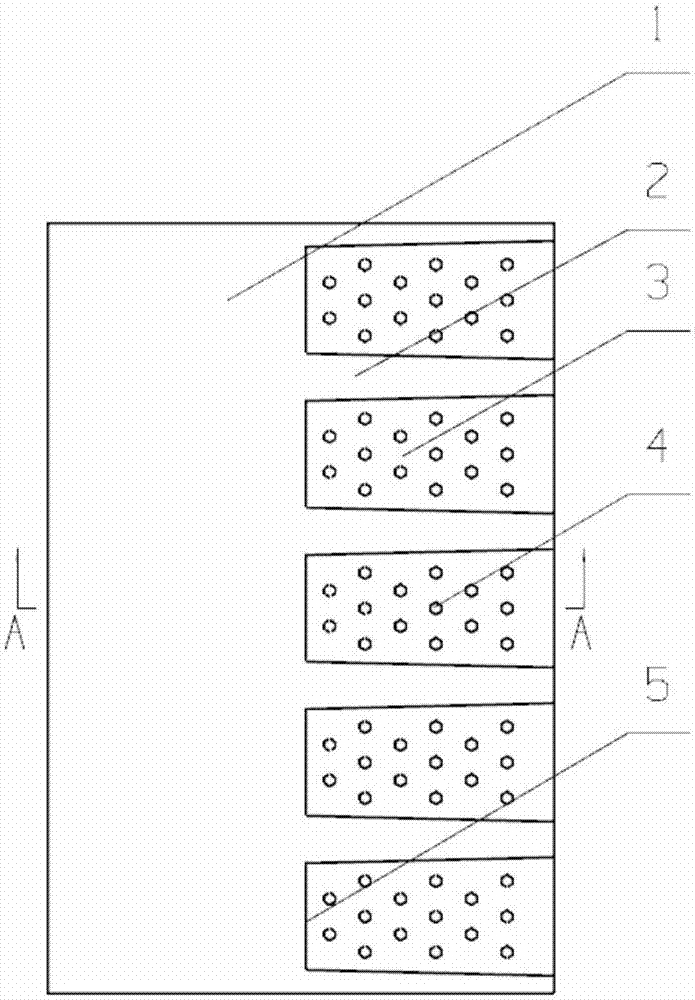

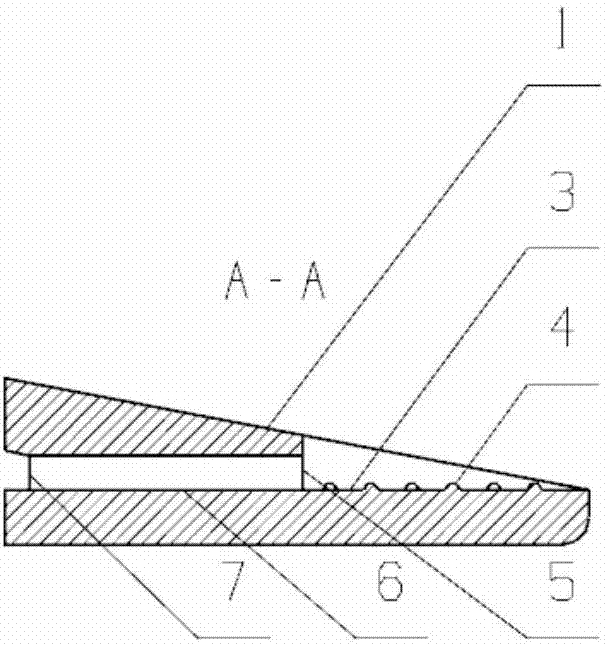

[0023] This embodiment is a turbine blade trailing edge turbulent half-slit cooling structure with spherical bumps.

[0024] refer to Figure 1 to Figure 6 In this embodiment, the turbine blade trailing edge turbulent half split cooling structure with spherical projections is applied to the turbine blade of an aero-engine. Suction surface 6, blade trailing edge pressure surface 1, trailing edge half-slit wall surface 3, partition rib 2, spherical bump 4, cold flow outlet 5, and cold flow inlet 7; among them, the part cut off from the blade trailing edge pressure surface 1 On the wall surface, the wall surface on the side where the suction surface 6 of the blade trailing edge is retained and the spaced partition ribs 2 form a plurality of half-slit structures; the ratio of the thickness t of the lip plate of the half-slit structure to the height s of the cold air outflow slot is 0.2 to 1.5, The inclination angle of the half-slit is 0-15°, and the cooling air flow is sprayed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com