Fire stirring device

A technology of inner tube and outer tube, which is applied in the field of energy-saving technical transformation of chain boilers, can solve problems such as insufficient mixing of fuel and combustion air, coking and ablation of the rod body, and poor safety performance, so as to solve thermal stress burst and avoid high temperature The effect of ablation, reliability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

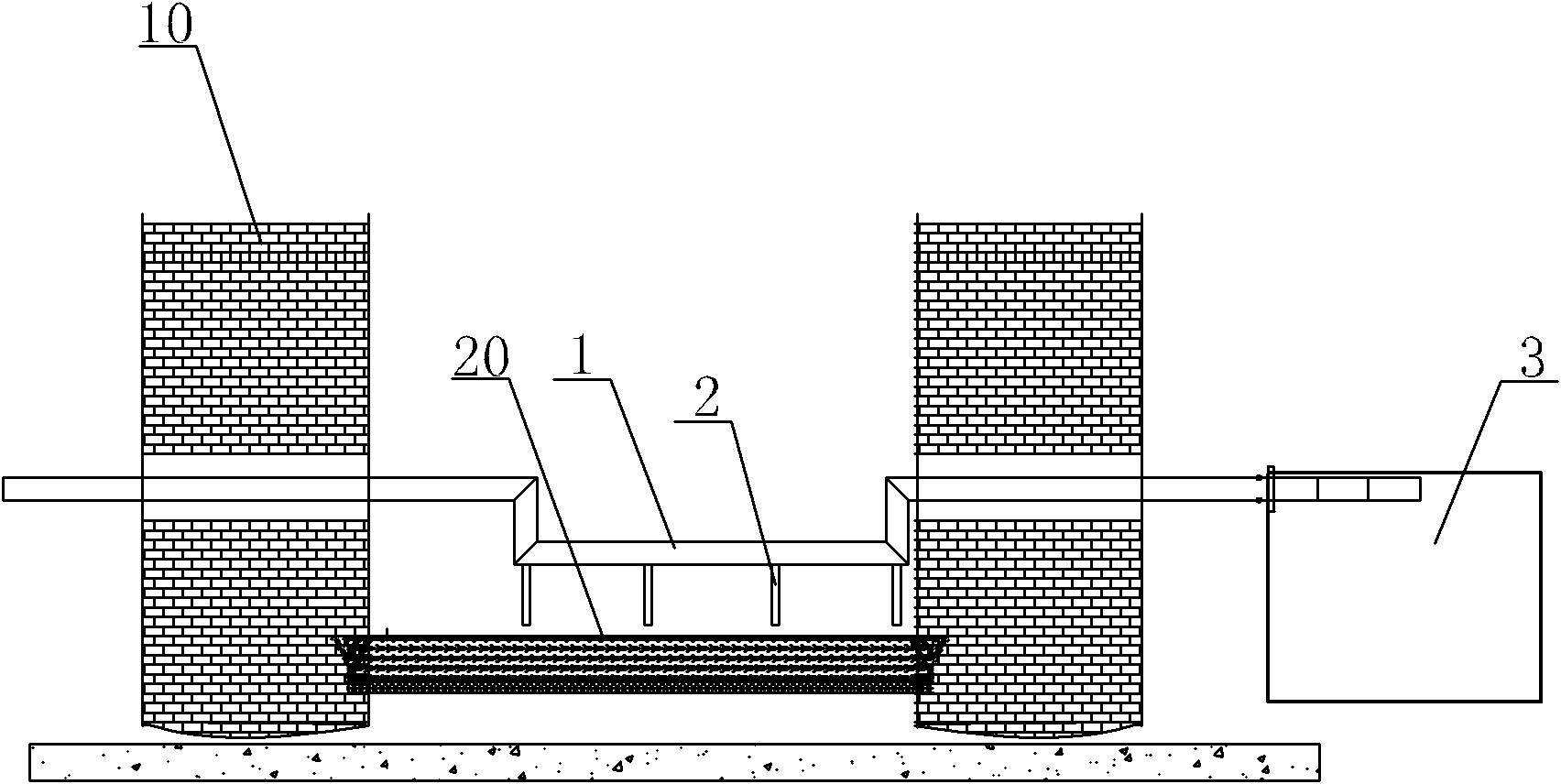

[0017] Such as figure 1 As shown, the fire poking device of the present invention is mainly used in chain boilers. The fire poking rod 1 is suspended inside the furnace of the chain boiler, and the straight teeth 2 passed through are stirred or turned over the coal on the chain 20, so that the coal can be fully burned. . The fire poker device of the present invention can greatly reduce the area of the poker rod, reduce the contact area between the poker rod and the fire, pass circulating cooling water into the poker rod 1, and keep the poker rod in a certain temperature range It can effectively ensure that the fire poker 1 will not be ablated due to high temperature.

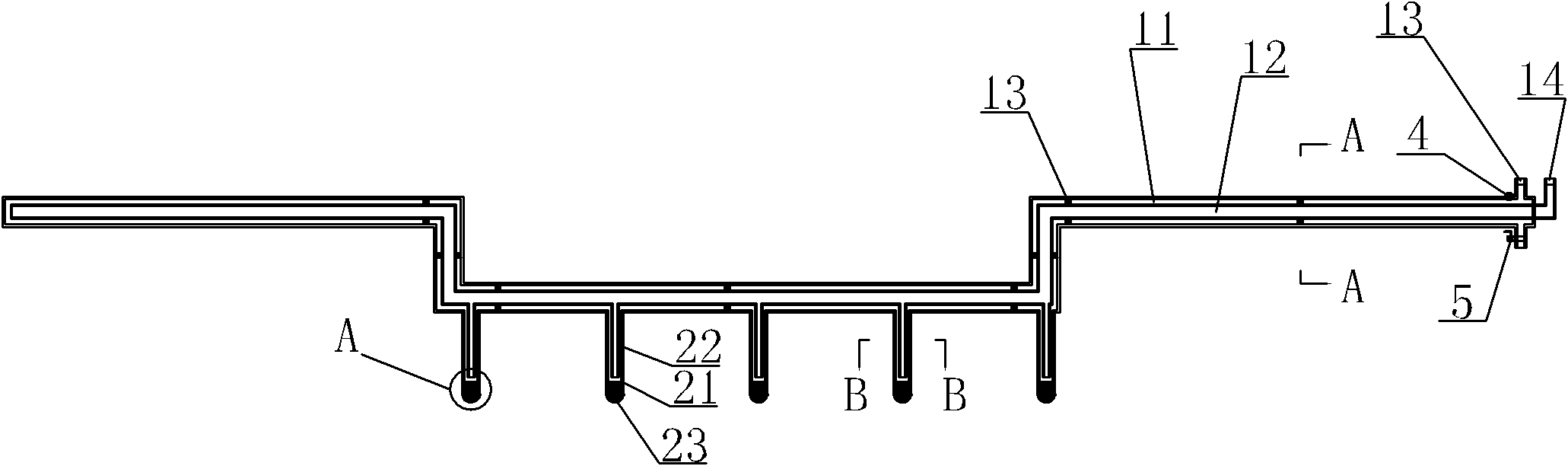

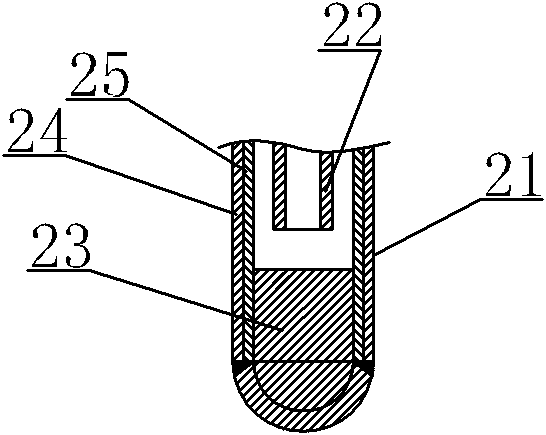

[0018] Such as figure 2 , image 3 , Figure 4 , shown in Fig. 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com