Circulating oil heat dissipation type low-noise transformer

A transformer and heat dissipation technology, which is applied in the field of circulating oil heat dissipation low-noise transformers, can solve the problems of large transformer noise, poor heat dissipation effect of transformers, and burnout of transformers, and achieve good heat dissipation effects, avoid resonance, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

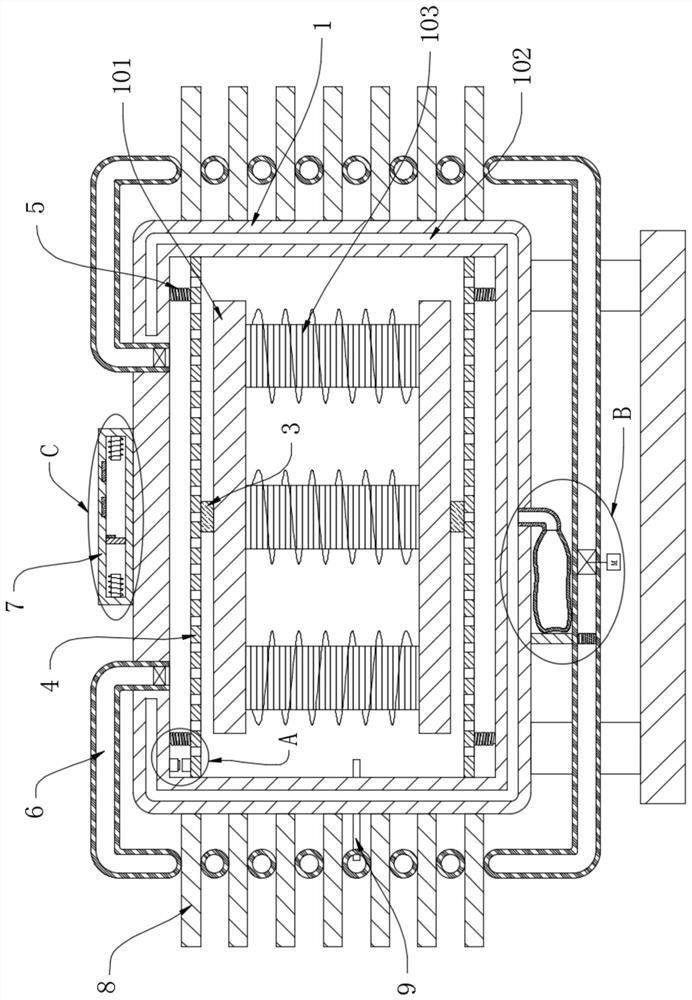

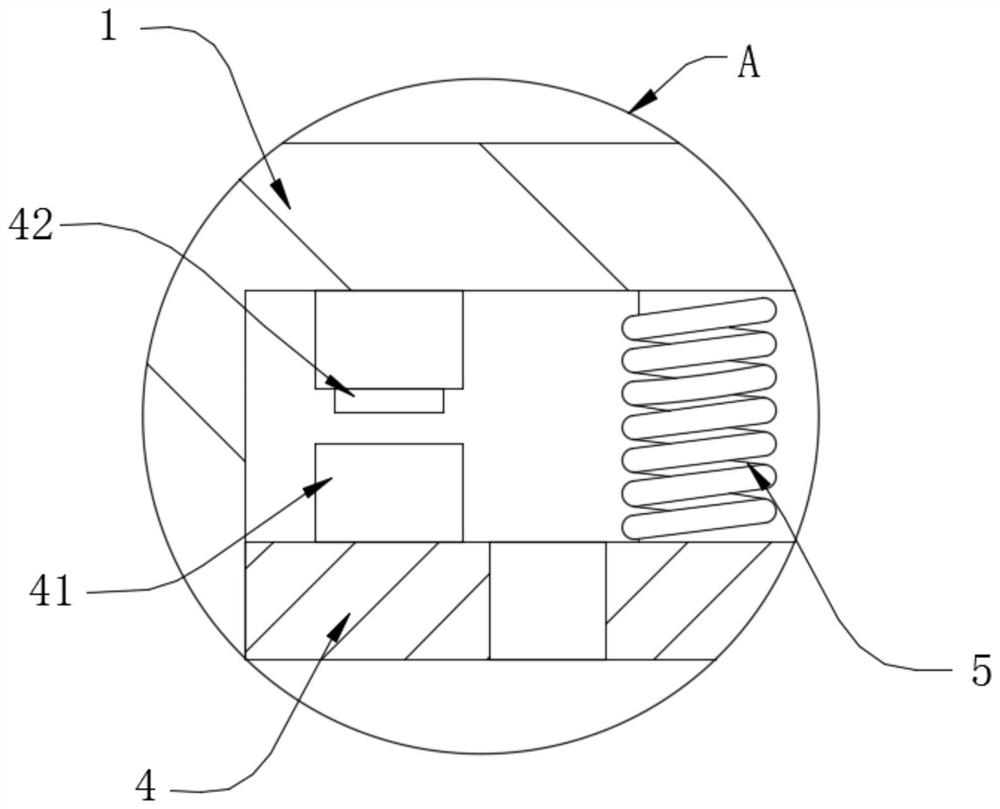

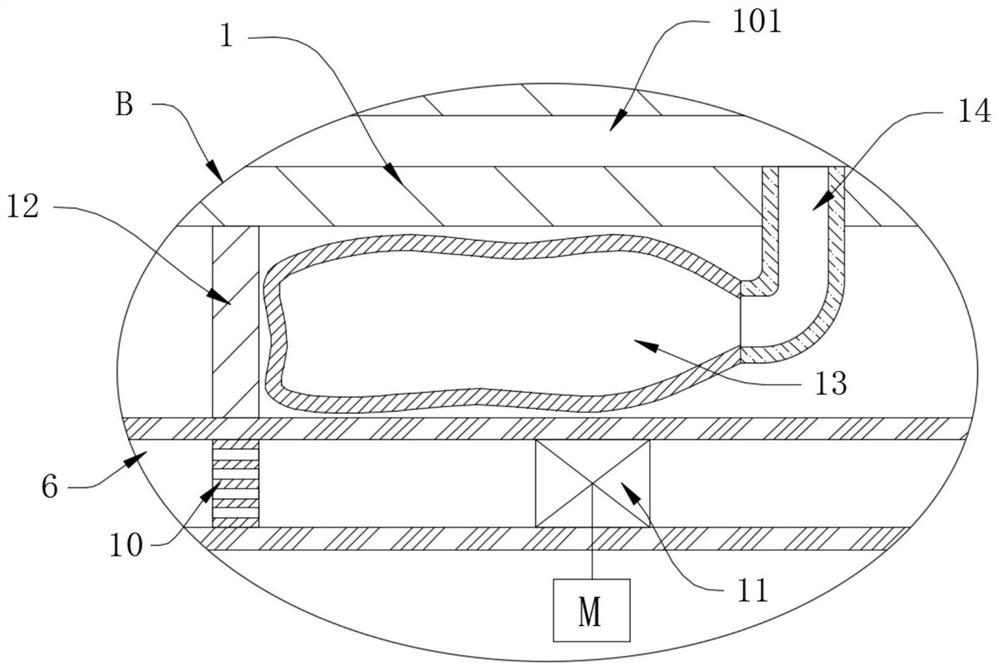

[0023] refer to Figure 1-5 , a circulating oil cooling type low-noise transformer, including a hollow transformer shell 1 and two fixing plates 101, the two fixing plates 101 are arranged inside the transformer shell 1, and the side walls of the two fixing plates 101 are welded with a number of iron The core 103 and the iron core 103 are formed by stacking a number of silicon steel sheets, and the side walls on the opposite side of the two fixing plates 101 are glued with the orifice plate 4 through the insulating bracket 3, and the orifice plate 4 is fixedly connected with the inner wall of the transformer shell 1 There are a number of springs 5, and the transformer shell 1 is fixedly connected with a circulating oil pipe 6. A check valve is provided at the left end of the circulating oil pipe 6, and only the transformer oil in the transformer shell 1 is allowed to enter the circulating oil pipe 6, and a check valve is provided at the right end of the circulating oil pipe 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com