A radial pin-fin structure solar heat absorber

A solar heat absorber and radial technology, applied in the field of solar heat absorbers, can solve the problems of easy oxidation and burning, poor reliability, burning and erosion of high temperature resistant materials, etc., and achieve the effects of improving safety and reliability, reducing thermal stress and improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

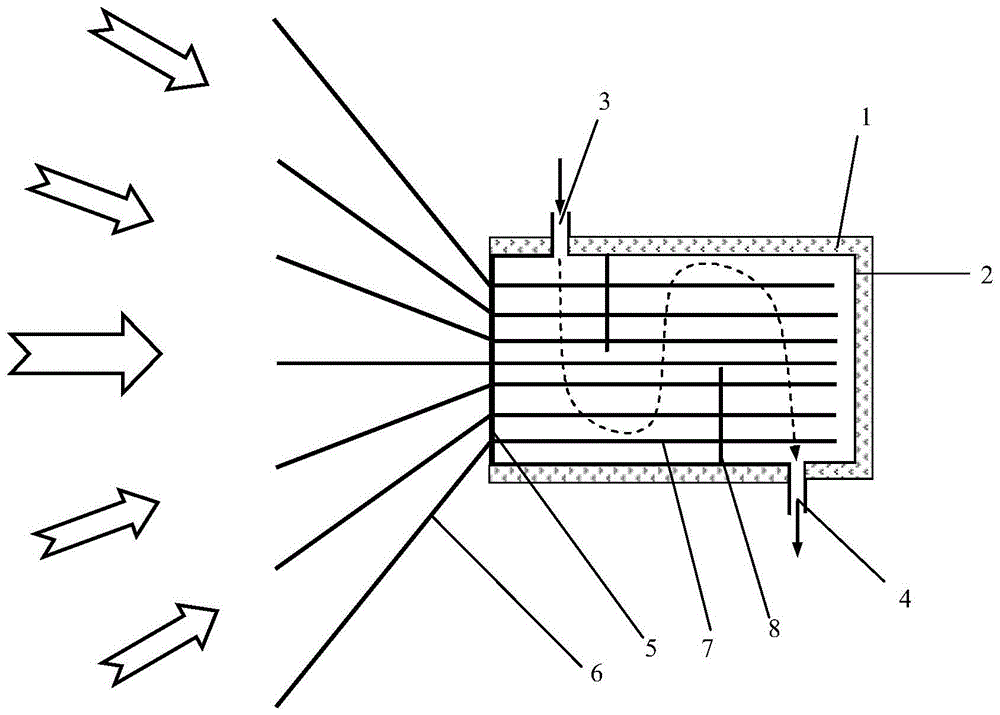

[0020] Such as figure 1 A solar heat absorber with a radial pin-fin structure shown includes an insulation layer 1, a shell 2, a working medium inlet 3, a working medium outlet 4 and a heat-absorbing surface 5, and the working medium inlet 3 and the working medium outlet 4 are respectively It is arranged at both ends of the shell 2, the outer wall of the shell 2 is wrapped with an insulating layer 1, and the inner wall of the shell 2 is provided with a rectifying plate 8; the entrance of the shell 2 is provided with a heat-absorbing surface 5, and the absorbing Radial outer pin fins 6 matching the transmission path of concentrated sunlight expand from the outer side of the thermal surface 5, and the outer pin ribs 6 are arranged from dense to sparse along the center to the outer periphery of the heat-absorbing surface 5, and the inner side of the heat-absorbing surface 5 expands Out of the inner needle rib 7. The cross sections of the outer pin ribs 6 and the inner pin ribs 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com