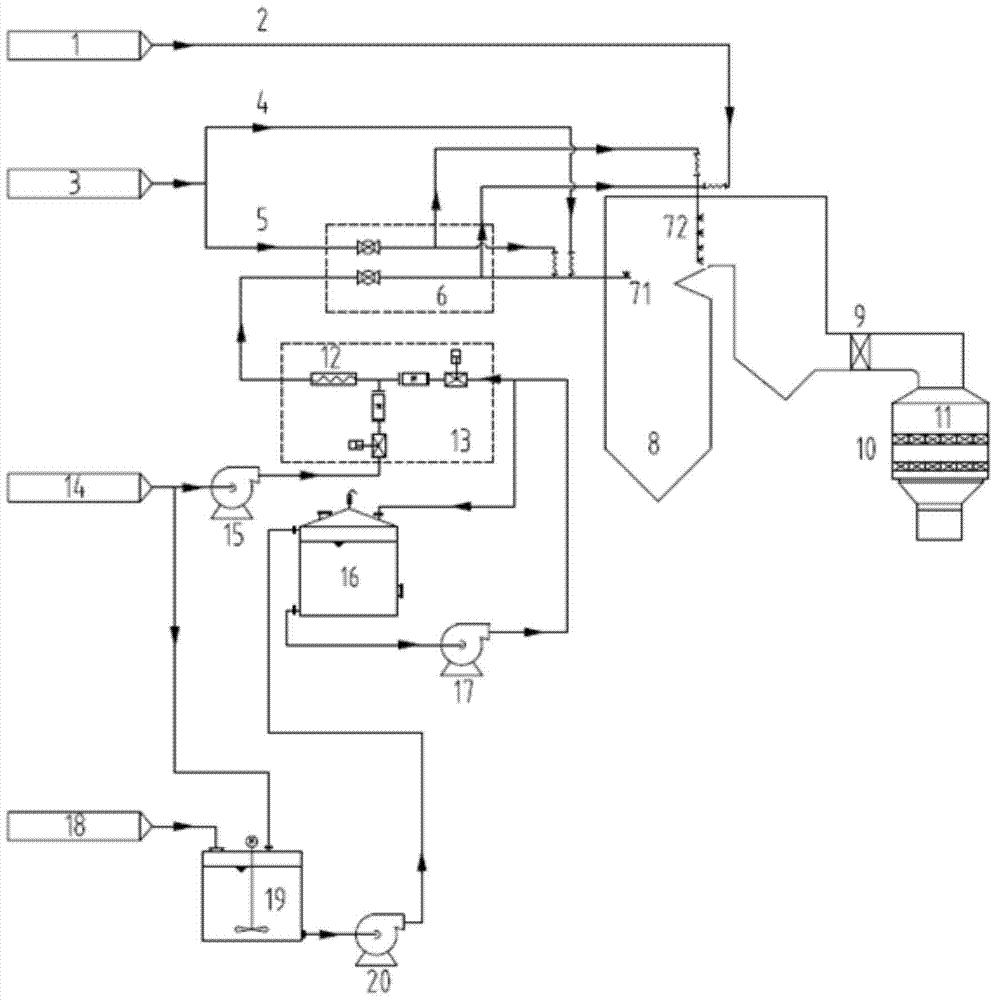

A coal-fired boiler sncr and scr combined denitrification system and method

A technology for coal-fired boilers and SCR reactors, applied in chemical instruments and methods, separation methods, lighting and heating equipment, etc., can solve problems such as uneven distribution, inability to mix evenly, corrosion, etc., and achieve uniform distribution of ammonia-nitrogen molar ratio, Efficient and low-cost removal and improved distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0031] The present invention is a coal-fired boiler SNCR and SCR combined denitrification method, through the short spray gun 71 and the multi-hole long spray gun 72 installed in the furnace chamber when the boiler SNCR reacts, and the flue gas mixer 9 and the SCR smoke installed in the tail flue of the boiler. Road reactor, no need to add SCR reductant injection device, overcome the low denitrification efficiency caused by uneven mixing of reductant and NOx in the existing process, equipment blockage and corrosion caused by large ammonia escape, and realize the overall comparison of SNCR and SCR systems High denitrification efficiency. At the same time, the SCR reactor can be modified by using the tail flue of the boiler, which saves the floor area required by the SCR project and reduces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com