A kind of internal combustion type kettle

A technology for hot water pots and water chambers, which is applied to water boiling utensils, cooking utensils, and household appliances. It can solve the problems of poor performance, increase the contact area between the flame and the wall of the hot water pot, and low thermal efficiency, and achieve improved thermal efficiency. , increase the residence time, improve the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

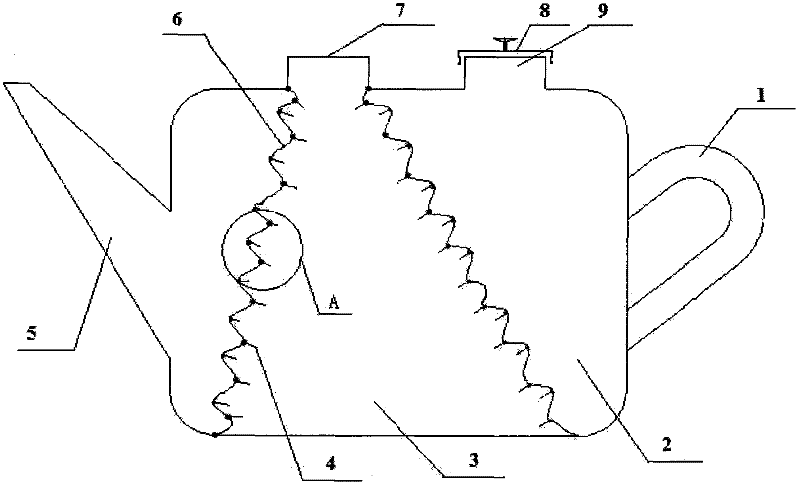

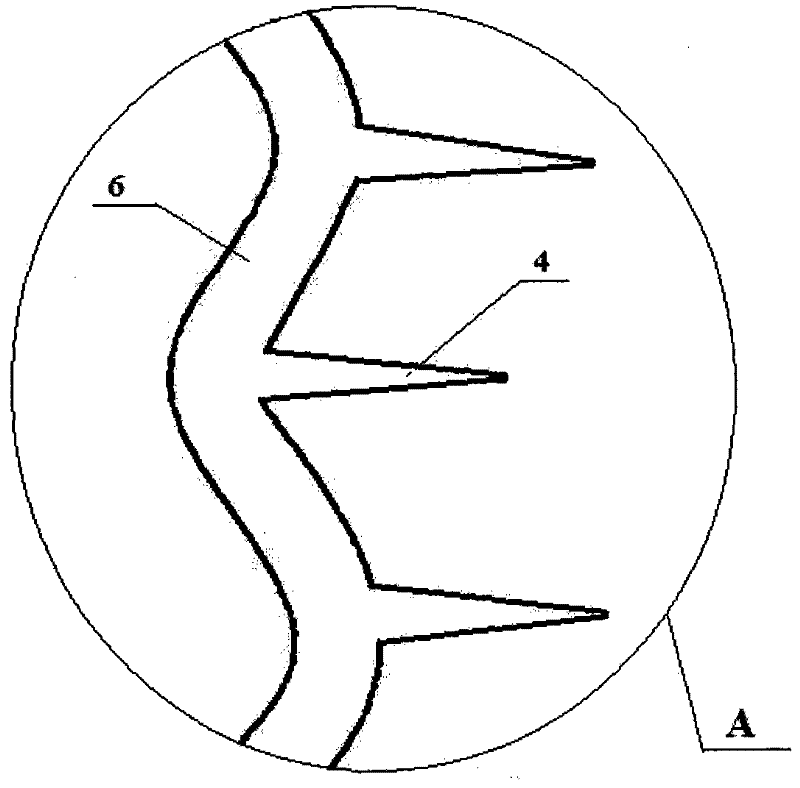

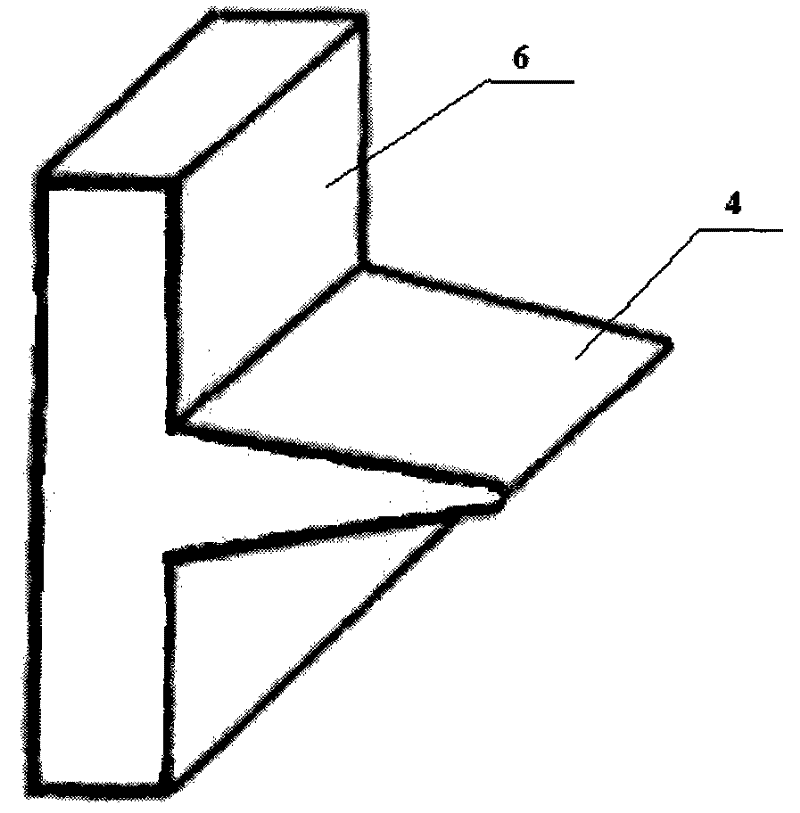

[0030] The present embodiment is an internal combustion type kettle. The internal combustion kettle mainly includes an internal combustion chamber 3, an annular water cavity 2, a curved wall 6, ribs 4, a water injection port 9, an exhaust port 7, a handle 1, a spout 5, and a lid 8.

[0031] as attached figure 1 As shown, the internal combustion kettle consists of two parts: an annular water chamber surrounded by an outer wall and an inner combustion chamber surrounded by an inner wall. The annular water chamber surrounds the inner combustion chamber; The inner wall of the sheet is a spiral corrugated curved surface; the exhaust port of the combustion chamber is located in the middle of the pot body, forming a whole that runs through from top to bottom. , forming a closed annular cavity. The upper part of the kettle, the curved wall of the combustion chamber and the outer wall of the water cavity are joined at the exhaust port; the lower part of the kettle, the curved wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com