Turbine blade tail edge turbulence half-crack cooling structure with continuous straight ribs

A technology of turbine blades and trailing edges, which is applied in the direction of blade support components, engine components, machines/engines, etc., to achieve good heat transfer characteristics, good processability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

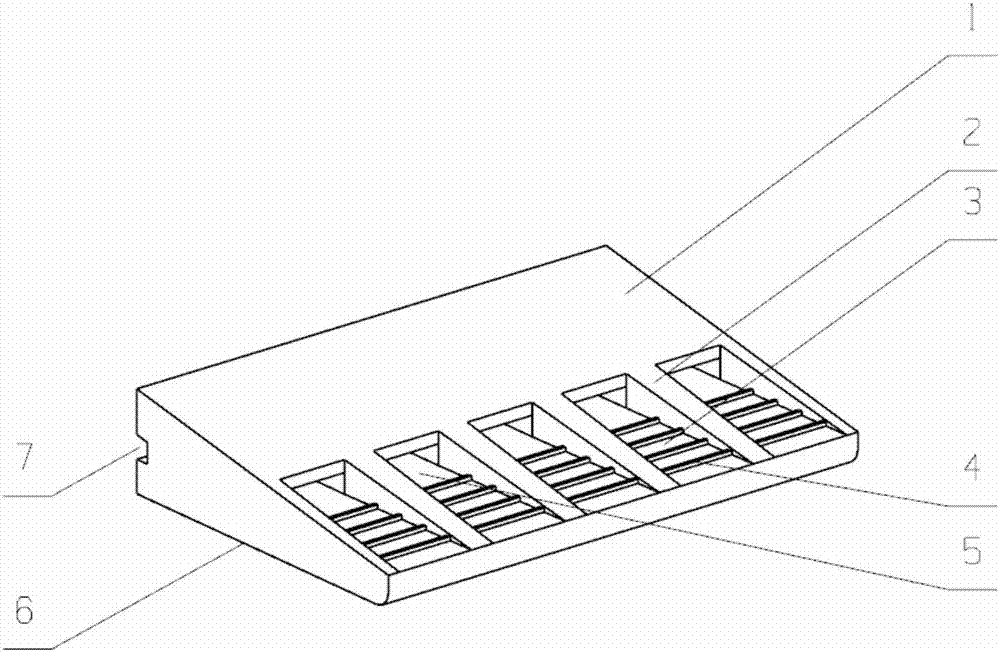

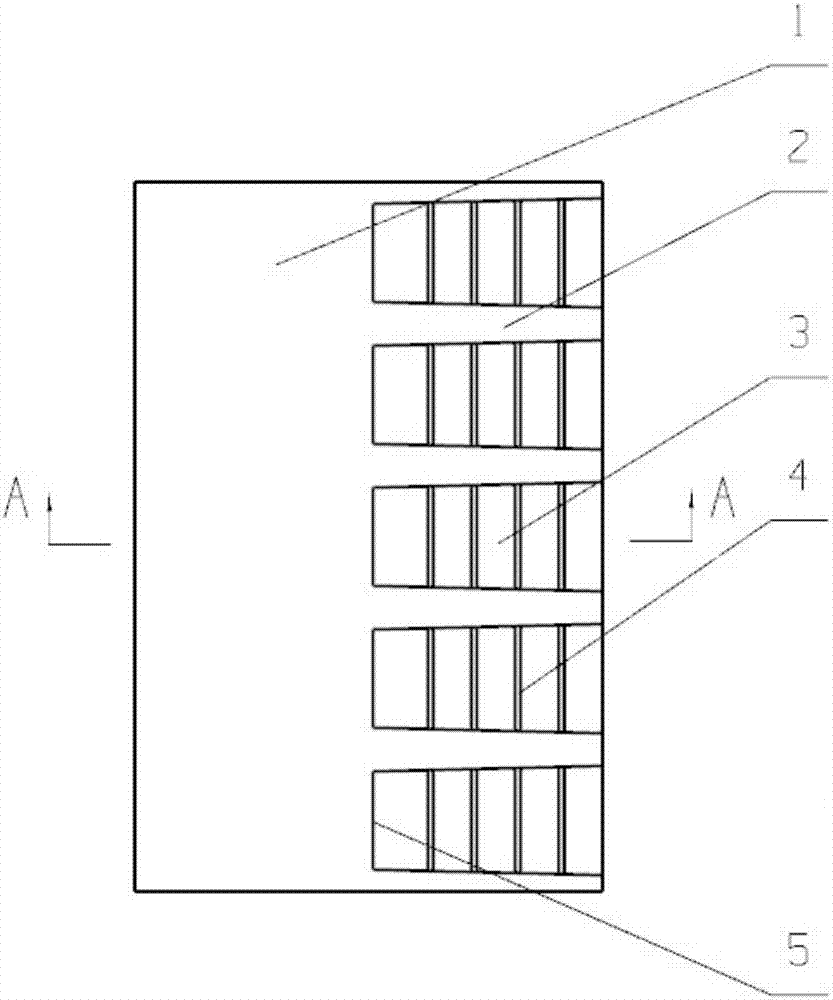

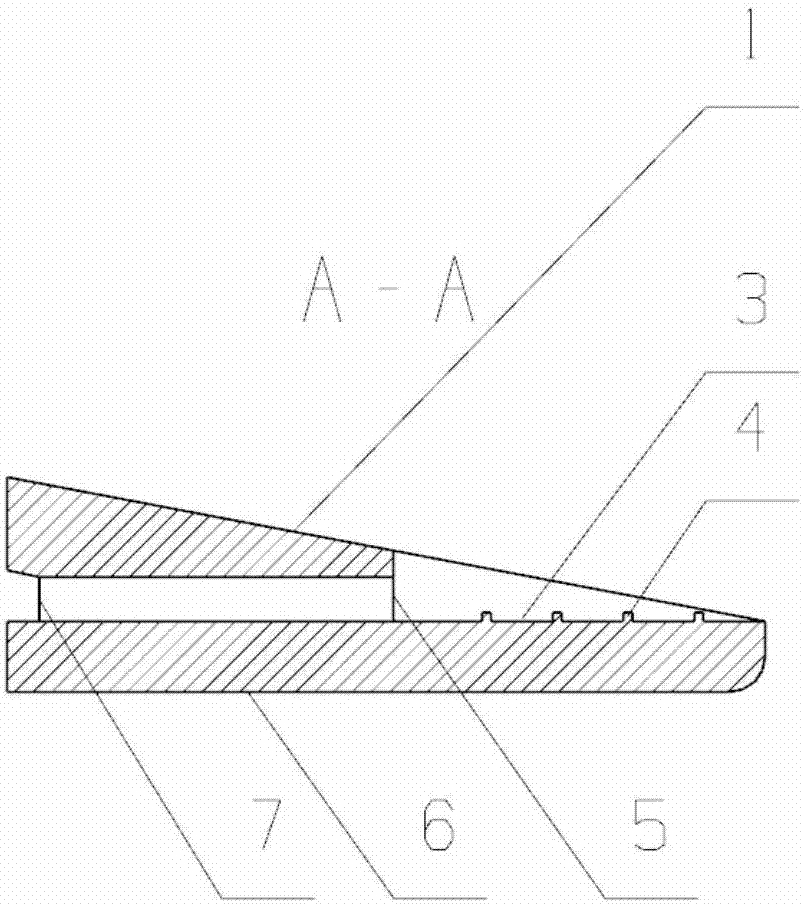

[0021] This embodiment is a turbine blade trailing edge turbulent half-slit cooling structure with continuous straight ribs.

[0022] refer to Figure 1 to Figure 6 , the present embodiment has the turbine blade trailing edge turbulence semi-slit cooling structure with continuous straight ribs applied to the trailing edge area 8 in the turbine blade of an aeroengine, consisting of the blade trailing edge suction surface 6, the blade trailing edge pressure surface 1, the Edge half split wall surface 3, partition rib 2, continuous straight rib 4, cold flow outlet 5, and cold flow inlet 7, wherein part of the wall surface is cut off at the pressure surface 1 of the blade trailing edge, and the wall surface on the suction side of the blade trailing edge is retained Form a plurality of half-slit structures with the spaced partition ribs 2; the ratio of the thickness t of the lip plate of the half-slit structure to the height s of the cold air outflow slit is 0.2 to 1.5, and the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com