Forced-draft burner and method for regularizing side-combustion high-temperature preheated air of square-box furnace

A technology of preheating air and forced ventilation, which is applied in combustion methods, gas fuel burners, burners, etc., and can solve problems such as low pressure, low combustion air temperature, and large combustion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

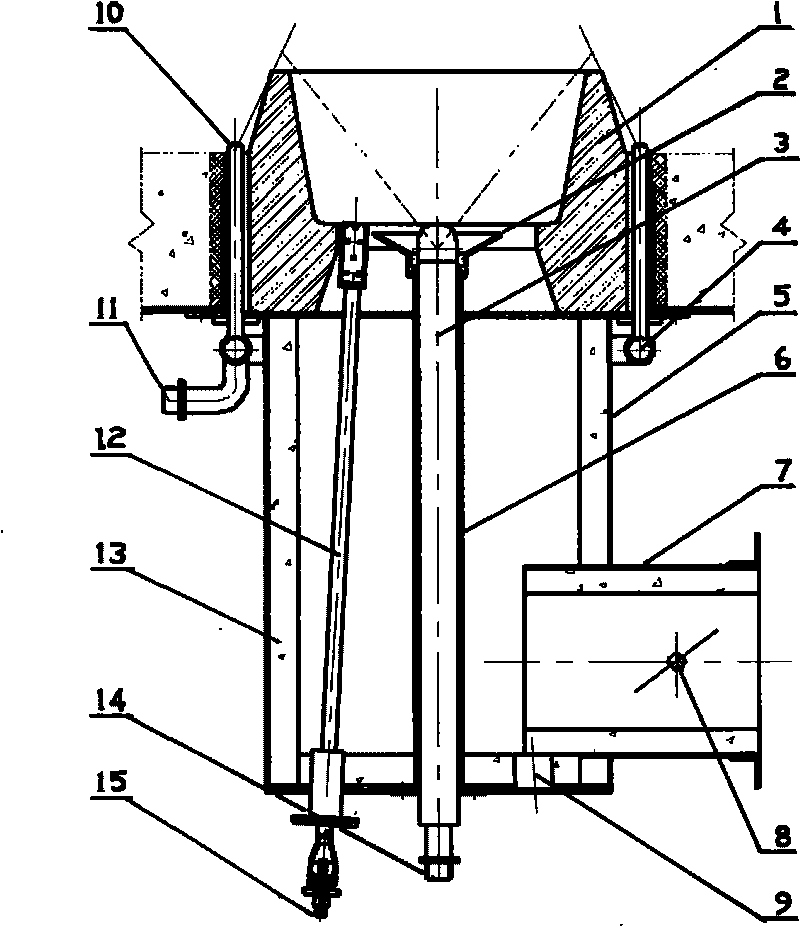

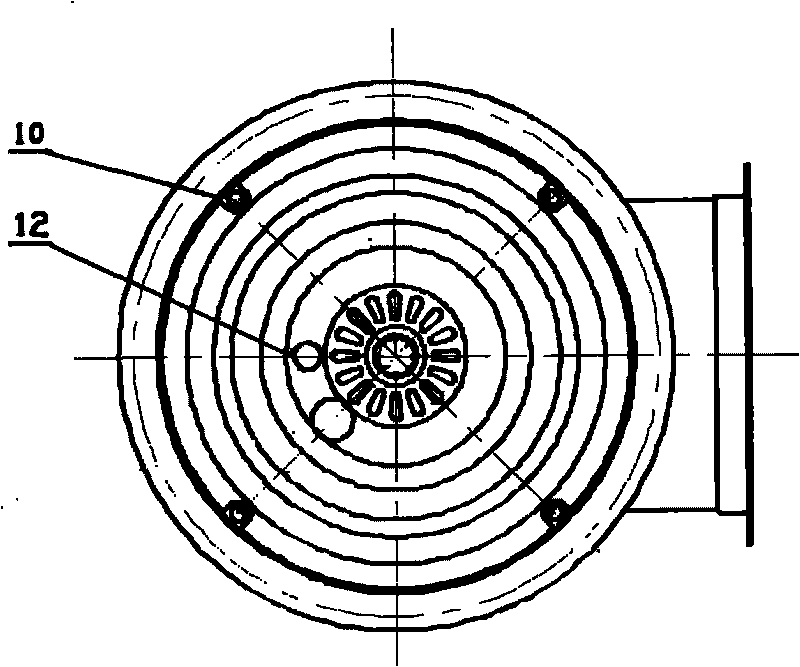

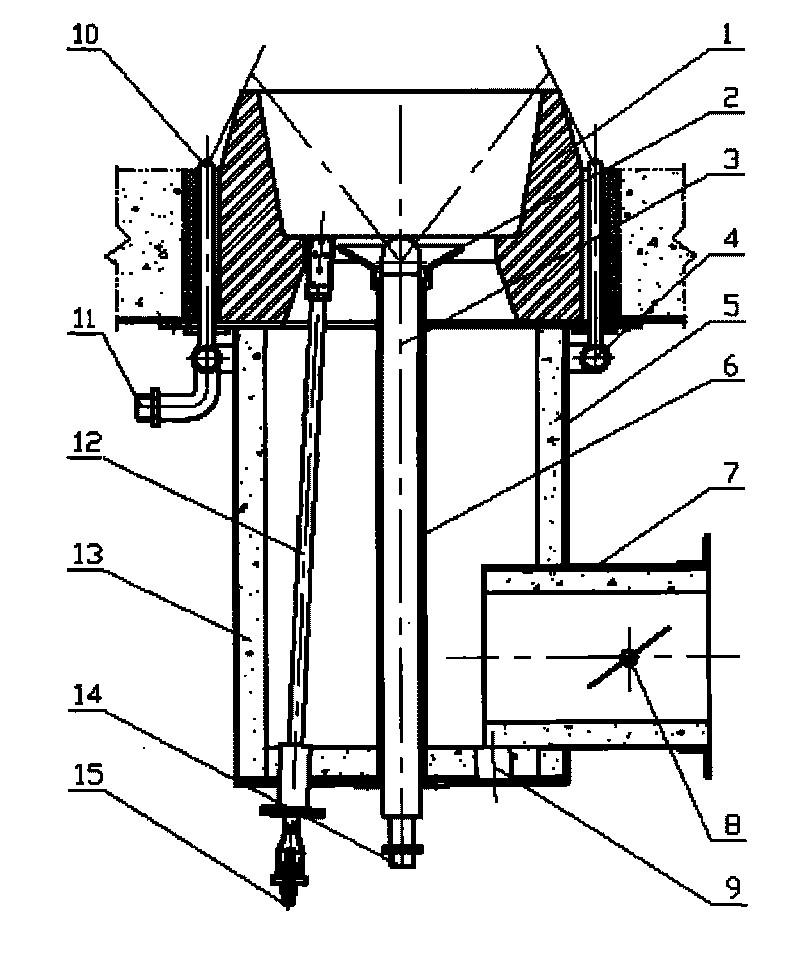

[0017] Embodiments of the present invention are described in conjunction with the accompanying drawings;

[0018] Such as figure 1 , 2 As shown, the side-fired high-temperature preheated air forced draft burner of a reforming square box furnace has a primary combustion system and a secondary combustion system. The primary combustion system is composed of a main gas gun 3 located in the center of the burner. The gas gun 3 is fixed on the center of the burner housing 5 by the gas gun casing 6, and its head is provided with a flame-stabilizing cover 2 and communicated with the combustion channel, the combustion channel is formed by the fire channel brick 1, and the outer edge of the gas channel brick 1 is above higher than the furnace body; the other end of the main gas gun 3 communicates with the gas source through the main gas inlet 14; the secondary combustion system is composed of multiple secondary gas guns 10 evenly distributed on the secondary gas distribution ring 4 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com