Cooled deposition baffle in high density plasma semiconductor processing

A plasma and baffle technology, used in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve the problems of destroying devices, increasing pollutants, etc., to reduce pollution, uniform heat flux, and uniform temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

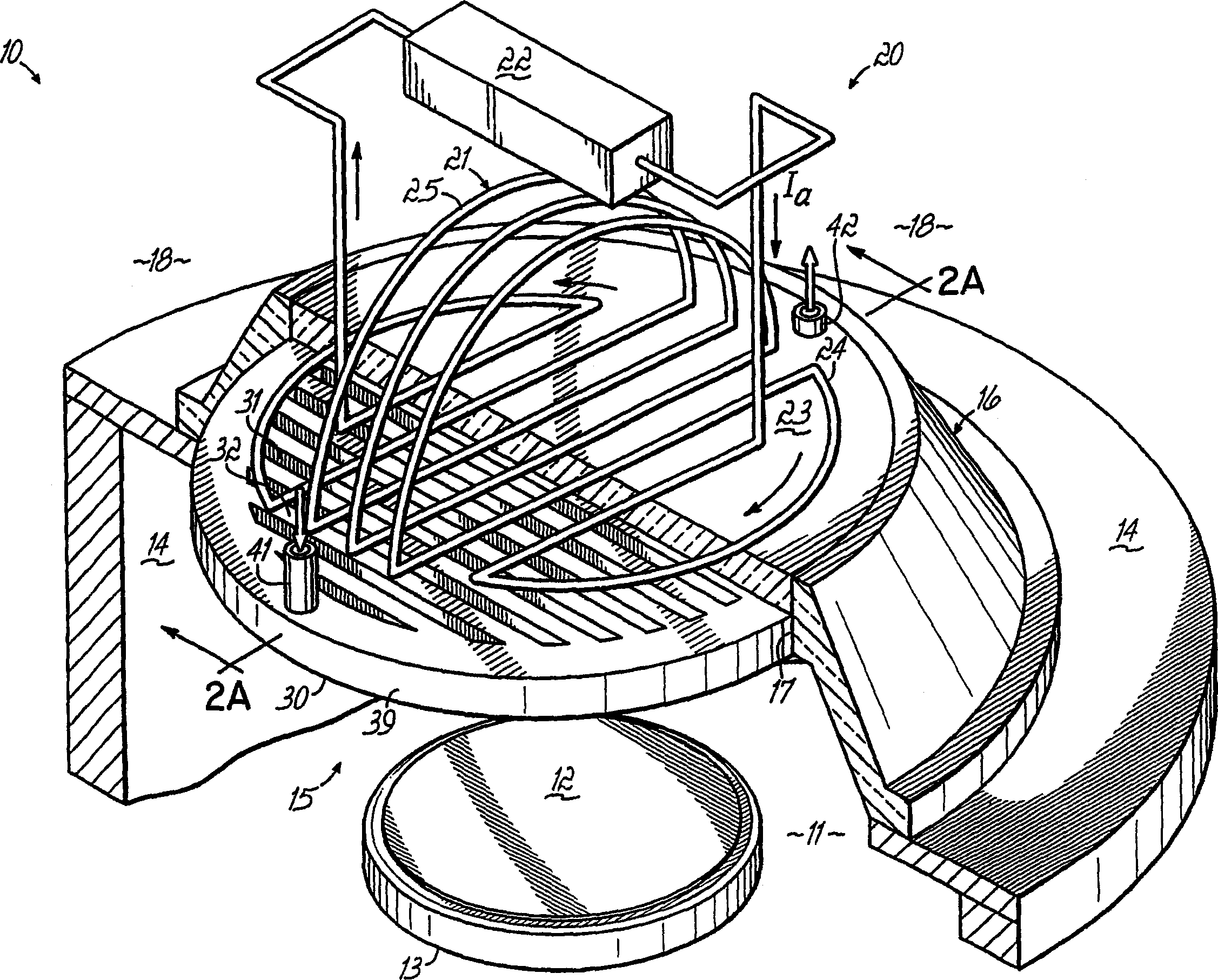

[0029] As shown in FIG. 1, an iPVD device 10 of the type described in the present invention is disclosed in US Patent No. 6,287,435. Apparatus 10 includes a vacuum chamber 11 bounded by chamber walls 14 and having, for processing therein, a semiconductor wafer 12 supported on an upwardly facing substrate support 13 . A source 15 of ionized sputtering material is located at the top of the vacuum chamber 11 and includes a frusto-conical magnetron sputtering target 16 with an RF energy source 20 located within an opening 17 of the target 16 . The RF energy source 20 includes an RF coil or antenna 21 connected to the output of the RF energy source and cooperating with a network 22 . The coil 21 is located in the atmosphere 18 outside the vacuum chamber 11, behind the dielectric window 23 forming a part of the chamber wall 14 of the vacuum chamber 11, which keeps the processing gas on the vacuum side in the vacuum chamber 11 with the atmosphere of the vacuum chamber 11. Isolated o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com