Axial permanent magnet assisted radial reluctance high-speed motor with hybrid cooling structure

A hybrid cooling and high-speed motor technology, applied in the direction of cooling/ventilation device, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve the problem of complex distribution of high-speed motor rotating fluid field, unable to fully take away heat from the motor, and cooling of high-speed motors Poor performance and other problems, to achieve the effect of lowering the maximum temperature, reducing copper consumption, and enhancing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

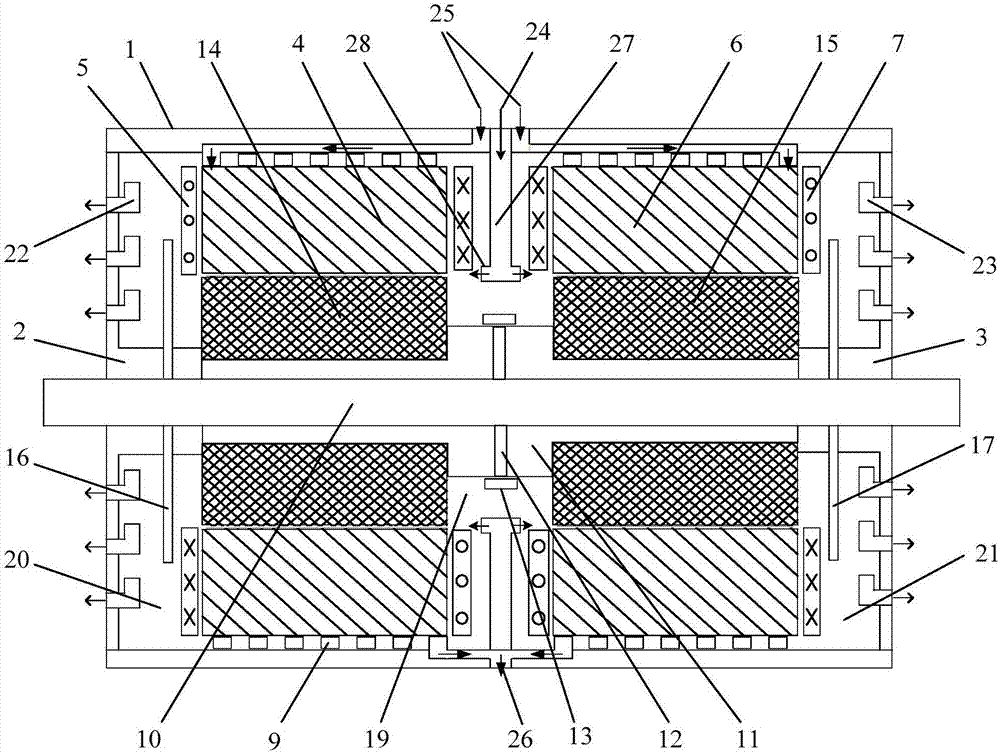

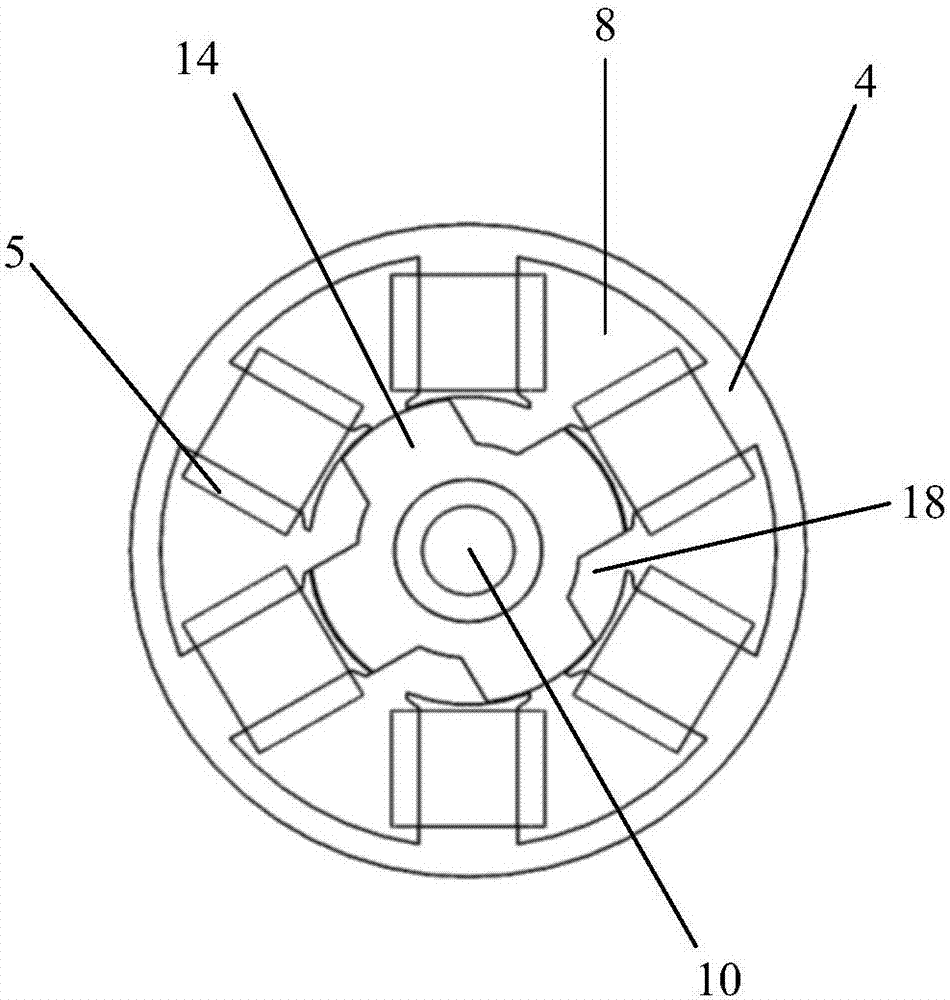

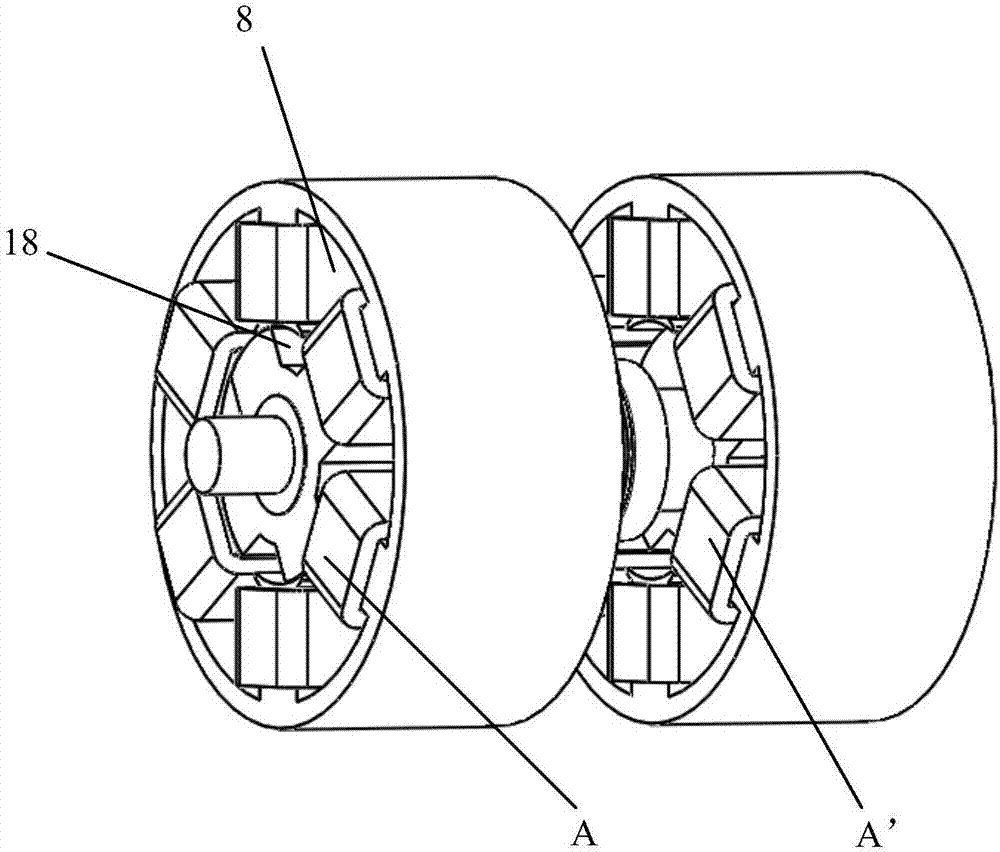

[0029] An axial permanent magnet assisted radial reluctance high-speed motor with a hybrid cooling structure, such as figure 1 As shown, it includes a casing 1, a front end cover 2, a rear end cover 3, a stator and a rotor. The basic structure of the motor is a double-group 6 / 4-pole switched reluctance motor structure. The structures on both sides of the motor (except for the rotor) are arranged in parallel and completely symmetrical to the middle vertical plane of the motor shaft. Six protrusions are evenly distributed on each side of the stator core. poles, and 4 salient poles are evenly distributed on each side of the rotor core, which is a double-set salient pole stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com