Fan-cooled rotor in shaft of high-speed permanent magnet motor

A permanent magnet motor, high-speed technology, applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of irreversible high-temperature loss of magnetism, large eddy current loss, and rotor temperature rise of the permanent magnet of the rotor, so as to avoid Effects of loss of magnetization problem, reduction of temperature rise, and enhancement of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

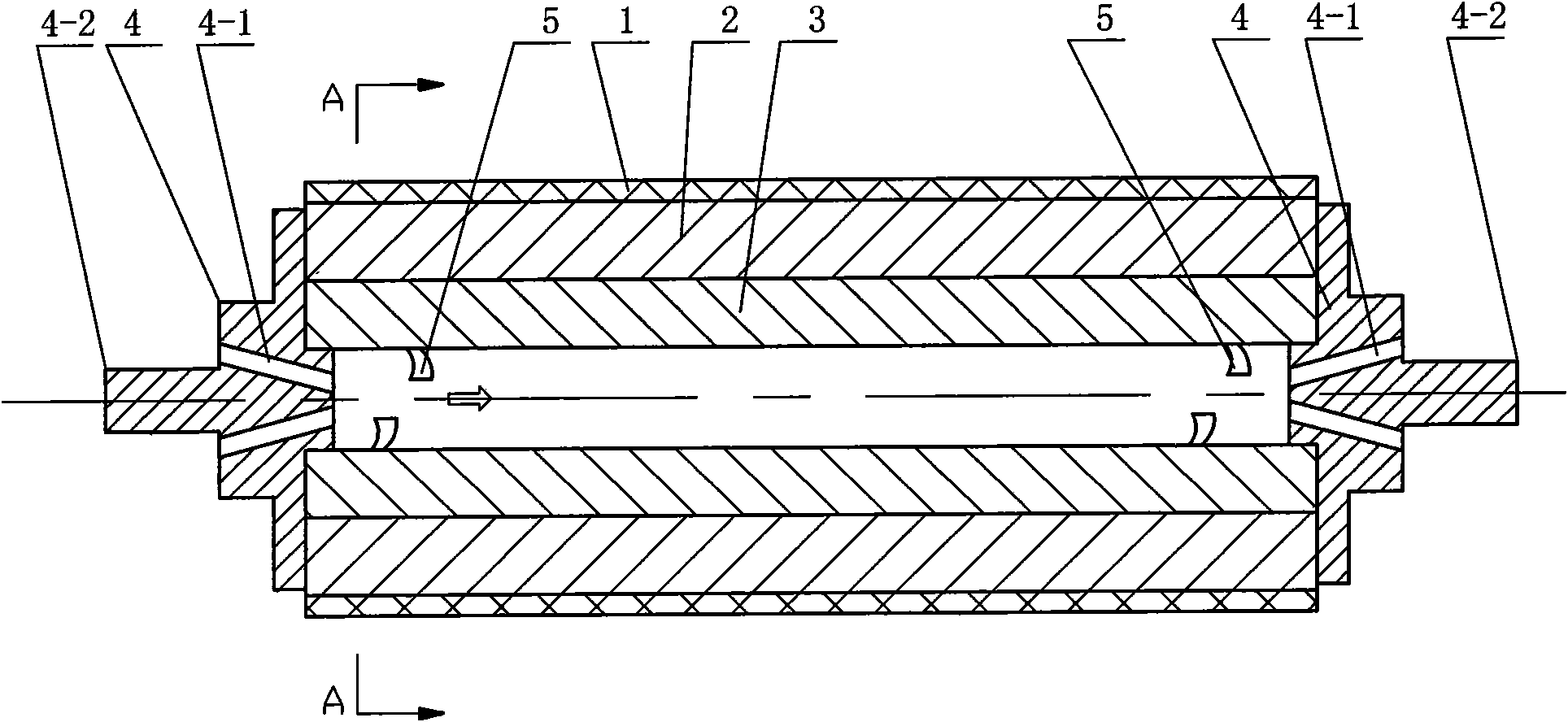

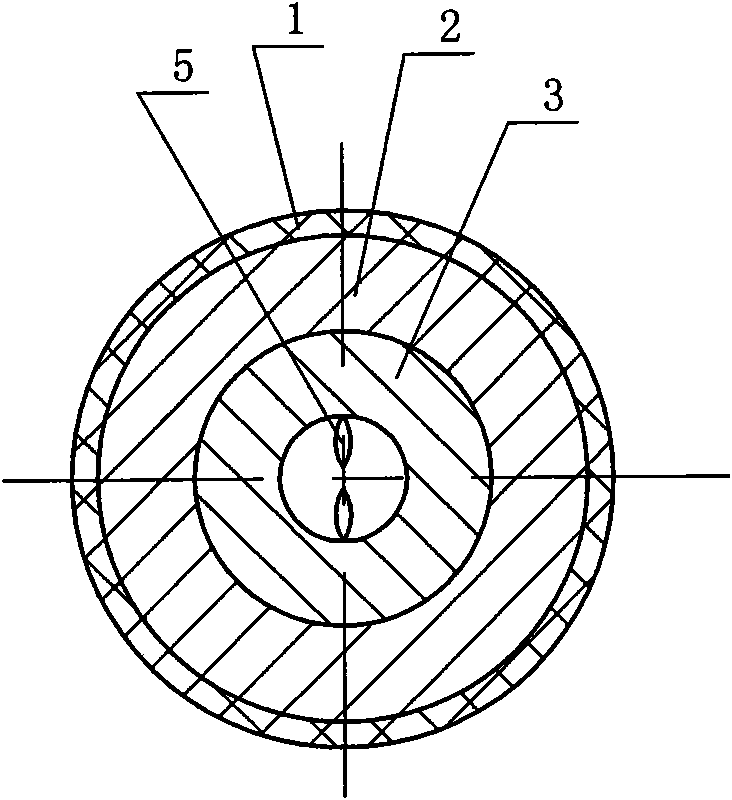

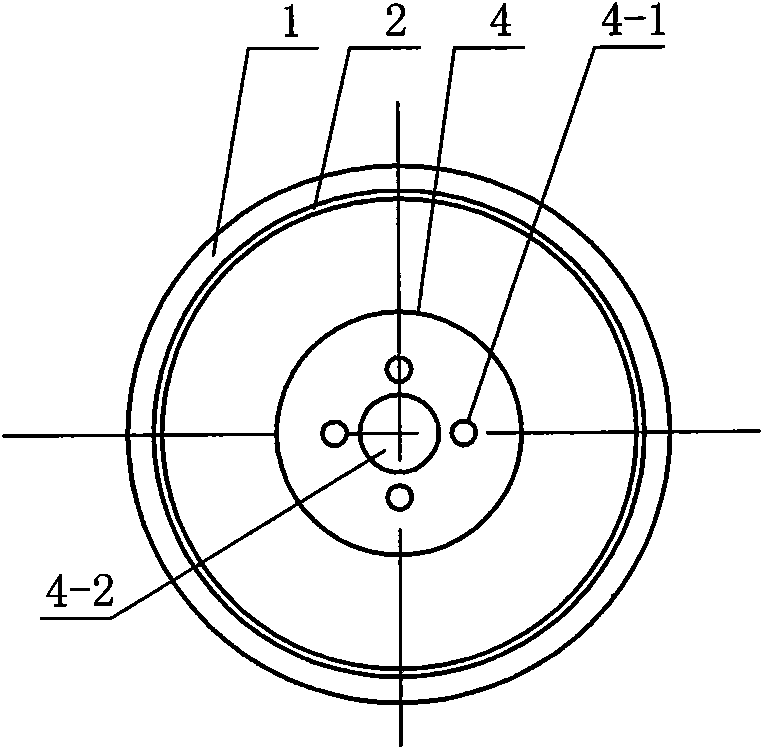

[0010] Specific implementation mode one: the following combination Figure 1 ~ Figure 3 Describe this embodiment, this embodiment comprises sheath or carbon fiber 1, permanent magnet 2 and rotor iron core 3, the permanent magnet 2 is encircled on the outer circular surface of rotor iron core 3, and the outer circular surface of permanent magnet 2 is provided with sheath or Carbon fiber 1, which also includes two end supports 4 and fan blades 5, the shoulders of the two end supports 4 are respectively interference fit with the two ends of the inner cavity of the rotor core 3, the end supports 4 and The rotor core 3 is coaxial, and the end support 4 is axially provided with a plurality of ventilation holes 4-1 communicating with the inner cavity of the rotor core 3 , and the inner cavity wall of the rotor core 3 is provided with fan blades 5 . When working, the output shaft 4-2 of the end support 4 is connected with the high-speed bearing of the motor to support the high-speed m...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the fan blade group 5 is a group of fan blade groups or two groups of fan blade groups, and the multiple fan blades of each group of fan blade group 5 are along the rotor core 3. The lumen wall is evenly distributed. Other components and connections are the same as those in Embodiment 1.

[0012] The multiple fan blades of each fan blade group 5 are evenly distributed along the inner cavity wall of the rotor core 3, which can enhance the stability of the motor when running at high speed.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the fan blade sets 5 form a set and are located at the air inlet end of the inner cavity wall of the rotor core 3 . Other components and connections are the same as those in Embodiment 2.

[0014] A group of fan blades are welded to the air inlet end of the inner cavity wall of the rotor core 3 to play the role of blowing air, and the self-fan cooling effect in the shaft is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com