Battery heat management system for electric vehicle with plate type heat pipe

A technology of battery thermal management and plate heat pipes, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as shortening charging time and increasing energy density, avoiding complexity and potential safety hazards, reducing maximum temperature, and improving consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

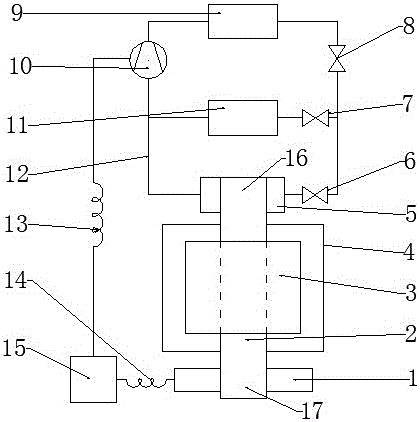

[0040]Embodiment 1: As shown in Figure 1, the electric vehicle battery thermal management system with plate heat pipes consists of a battery pack, a cooling system, a heating system and a control module 15. The battery pack is composed of a plurality of battery cells 3 , plate heat pipes 2 inserted between the battery cells 3 and a frame 4 . In this embodiment, the plate heat pipe 2 is a flat plate structure placed vertically. One end of the plate heat pipe along the length direction is a cooling end 16, and the other end is a heating end 17. The cooling end 16 of the plate heat pipe 2 is attached to the cooling plate 5 in the cooling system, and the heating end 17 is attached to the heating element 1 in the heating system. The middle part is attached to the battery cell 3 . There are multiple passages in the plate heat pipe 2, which are sealed by vacuuming, and the passages are filled with a working medium for phase change heat transfer. The cooling system is composed of an...

Embodiment 2

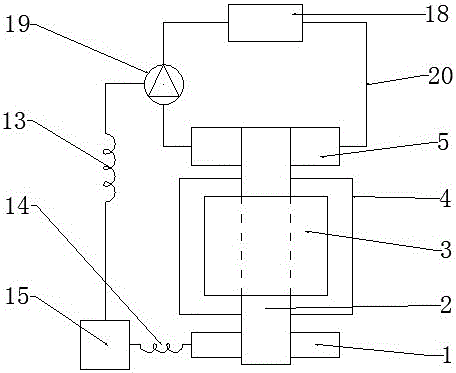

[0041] Example 2: If figure 2 As shown, in this embodiment, the cooling system is composed of a cooling plate 5 , a liquid pipeline 20 , a cooling module 18 and a water pump 19 . The heat dissipation module 18 is composed of a radiator and a fan, or is composed of a cooling device. This is a liquid-cooling system that also shares the same liquid-cooling system that the car uses to cool the engine. Other structures and working principles of this embodiment are the same as those of Embodiment 1.

Embodiment 3

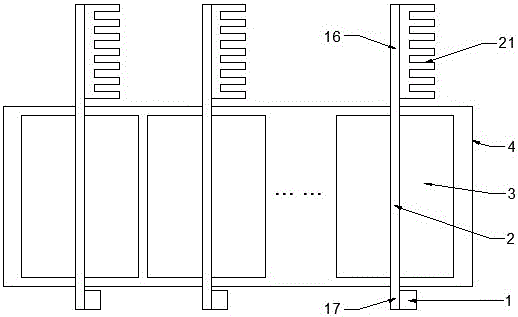

[0042] Example 3: image 3 It is a schematic diagram of the thermal conduction structure of the electric vehicle battery thermal management system with a plate heat pipe according to the present invention. The battery pack is composed of a plurality of battery cells 3, and the shape of the battery cells 3 is a cuboid. The plate heat pipe 2 is inserted between the electric cores 3, and its shape is L-shaped. The bottom edge of the L shape is the heating end 17, which is attached to the heating element 1, and the cooling plate 5 is attached to the cooling end 16 of the plate heat pipe 2. The entire battery pack is connected as a whole through the frame 4 . Other structures and working principles of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com