Low-entropy mixed-fuel engine

A technology of engines and combustion chambers, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of low cooling medium temperature, low heat grade, low heat grade, etc., and achieve the effect of improving the degree of load response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

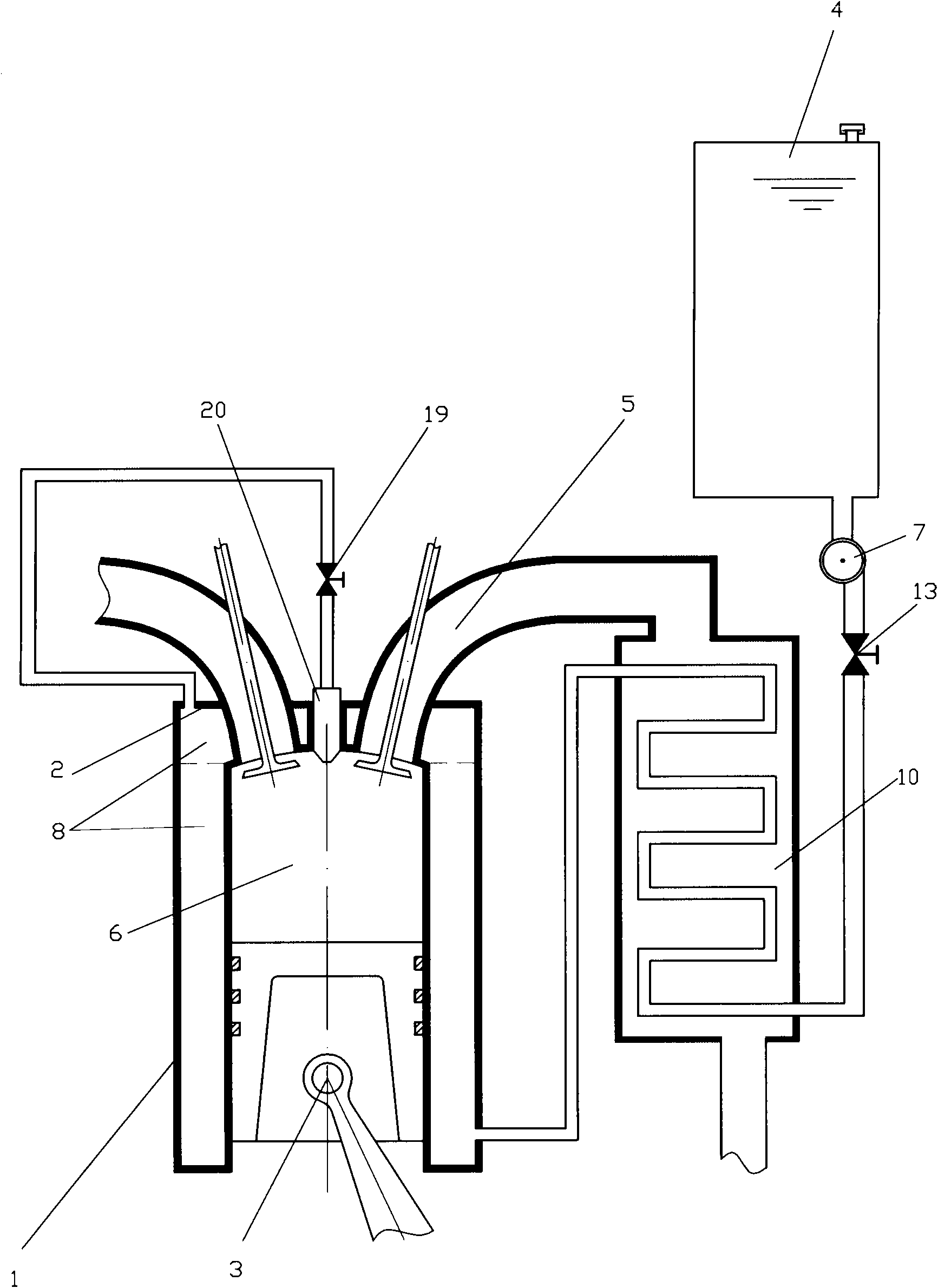

[0061] Such as figure 1The low-entropy co-combustion engine shown includes a cylinder 1, a cylinder head 2, a piston 3, a working medium storage tank 4, an exhaust passage 5 and a combustion chamber 6, and the inside of the side wall of the cylinder 1 and the inside of the cylinder head 2 are provided with high pressure The fluid channel 8, the pressure bearing capacity of the high-pressure fluid channel 8 is greater than or equal to 1MPa, the low-entropy co-combustion engine also includes an exhaust heat exchanger 10, and the exhaust channel 5 communicates with the heating fluid inlet of the exhaust heat exchanger 10; The outlet of tank 4 communicates with the heated fluid inlet of exhaust heat exchanger 10 through high-pressure pump 7, and the heated fluid outlet of exhaust heat exchanger 10 communicates with the inlet of high-pressure fluid passage 8; the outlet of high-pressure fluid passage 8 is sprayed The control valve 19 communicates with the steam injector 20, the ste...

Embodiment 2

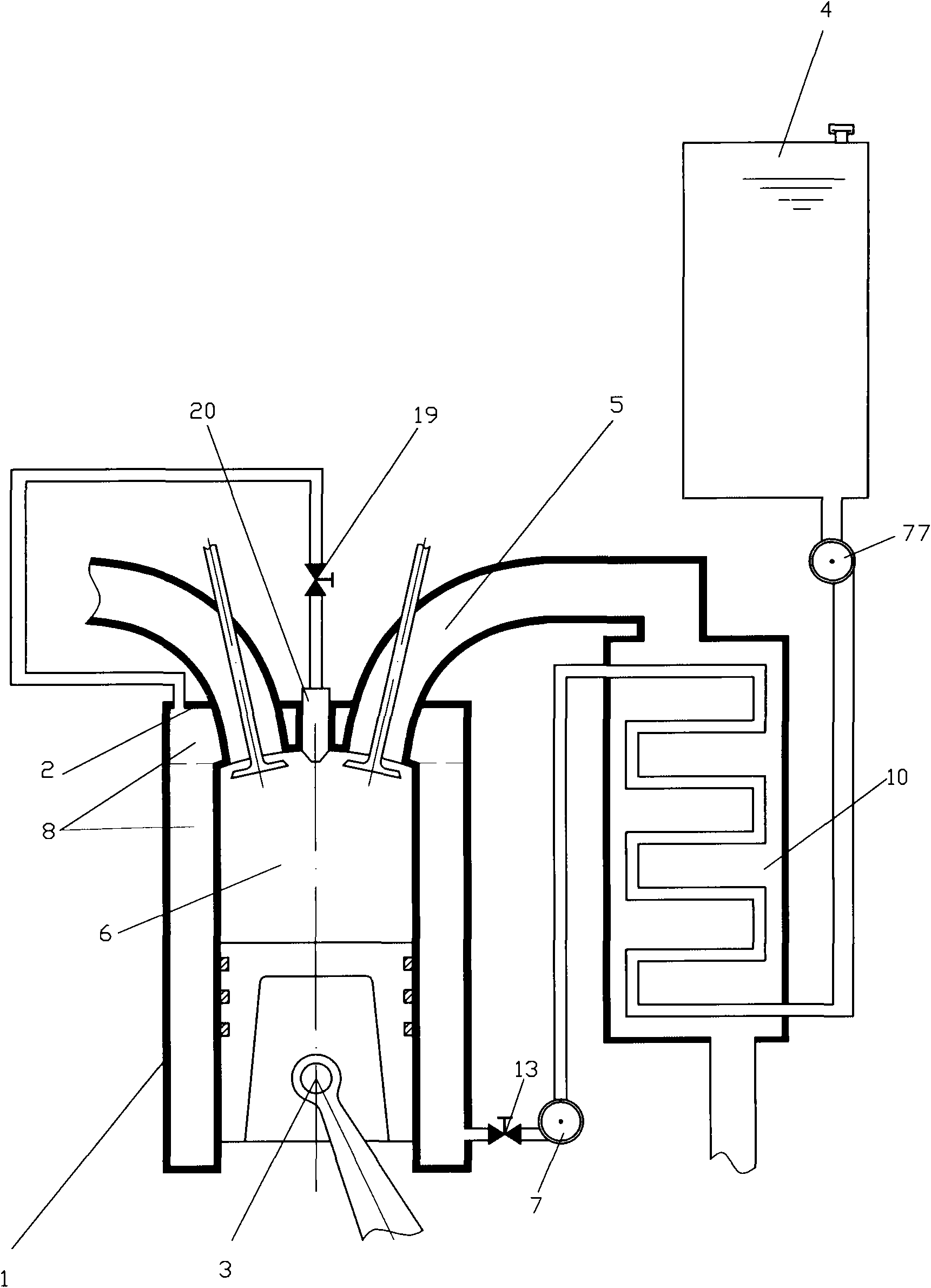

[0064] Such as figure 2 The difference between the shown low-entropy co-combustion engine and Embodiment 1 is that the outlet of the working fluid storage tank 4 communicates with the heated fluid inlet of the exhaust heat exchanger 10 through the high-pressure fluid pump 77, and the exhaust heat exchanger 10 The heated fluid outlet is communicated with the inlet of the high-pressure fluid channel 8 through the high-pressure pump 7 . The pressure-bearing capacity of the high-pressure fluid channel 8 is greater than or equal to 2MPa. A total flow control valve 13 is arranged at the outlet of the high-pressure fluid pump 77 to control the total flow of the required working fluid. When the low-entropy mixed-combustion engine is working normally, the high-pressure The cooling medium in the fluid channel 8 is in a supercritical state.

[0065] The purpose of installing the high-pressure fluid pump 77 is to ensure the circulation pressure of the vaporized cooling medium and ensure...

Embodiment 3

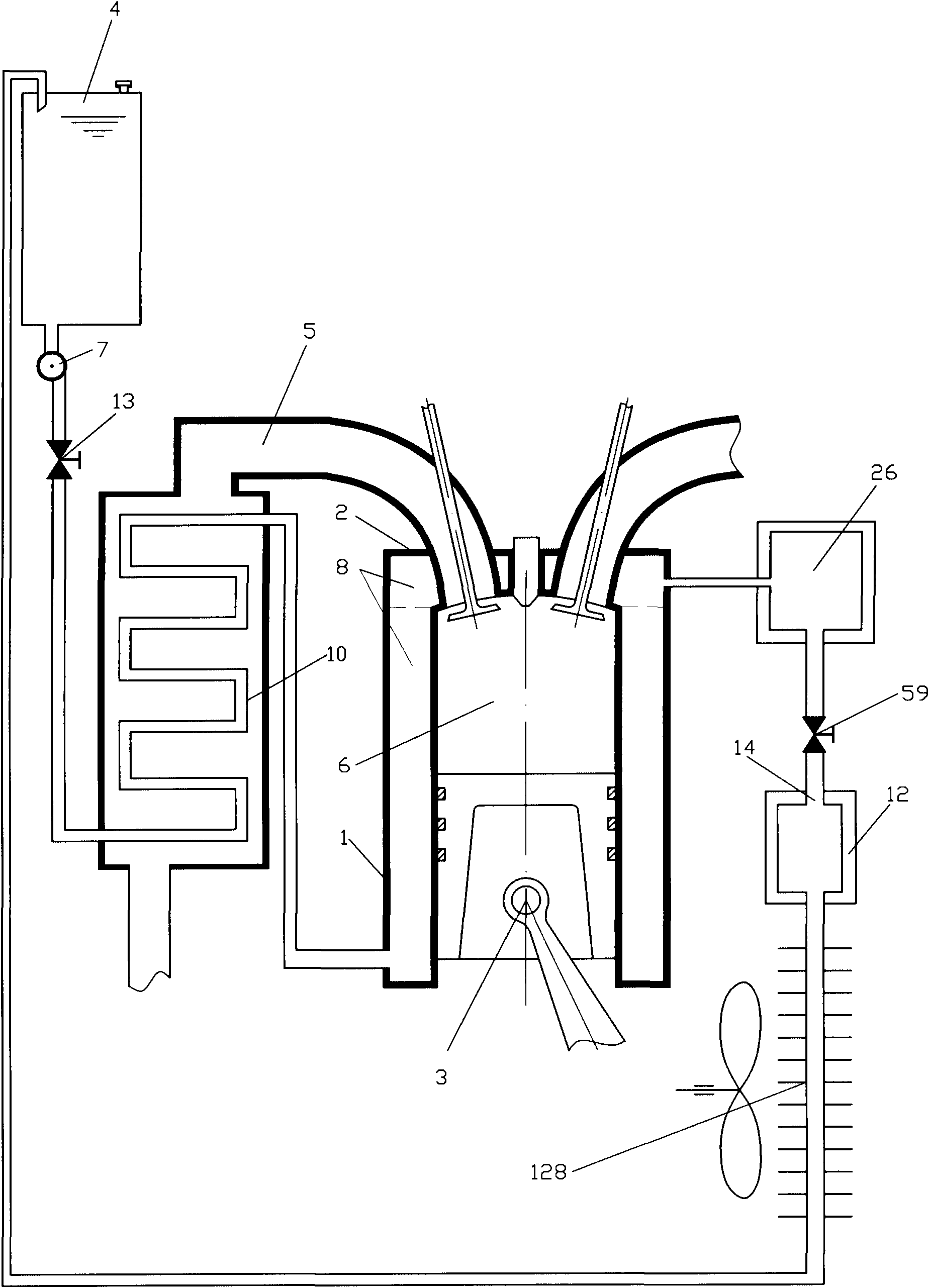

[0067] Such as image 3 The difference between the shown low-entropy co-combustion engine and Embodiment 1 is that the outlet of the high-pressure fluid passage 8 communicates with the working medium inlet 14 of the heat engine 12 through the flow control valve 59, and the high-temperature and high-pressure fluid generated in the high-pressure fluid passage 8 The working medium pushes the heat engine 12 to do work. A high-pressure working fluid storage tank 26 is installed before the flow control valve 59, which can meet the requirements of the peak power of the engine and balance the pressure of the steam system. When the engine needs a large peak power, the steam injection volume of the cylinder can be increased to increase the output power of the engine. . A closed condensing cooler 128 is arranged at the working medium outlet of the heat engine 12, and the liquid outlet of the closed condensing cooler 128 communicates with the working medium storage tank 4, so that the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com