Lining structure concrete water cooling water temperature control method

A water temperature control method and water cooling technology, applied in infrastructure engineering, water conservancy engineering, hydroelectric power generation and other directions, can solve problems such as poor scientificity, no theoretical support, and irrationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] 2 # Water cooling of the lining concrete of the fourth unit of the spillway tunnel

[0108] Such as Figure 4 shown, 2 # The thickness of the lining structure of the fourth unit in the upper flat section of the spillway tunnel is 2.5m, which is C 90 40 low heat concrete. The side wall lining concrete will be poured on May 12, 2017, as an example.

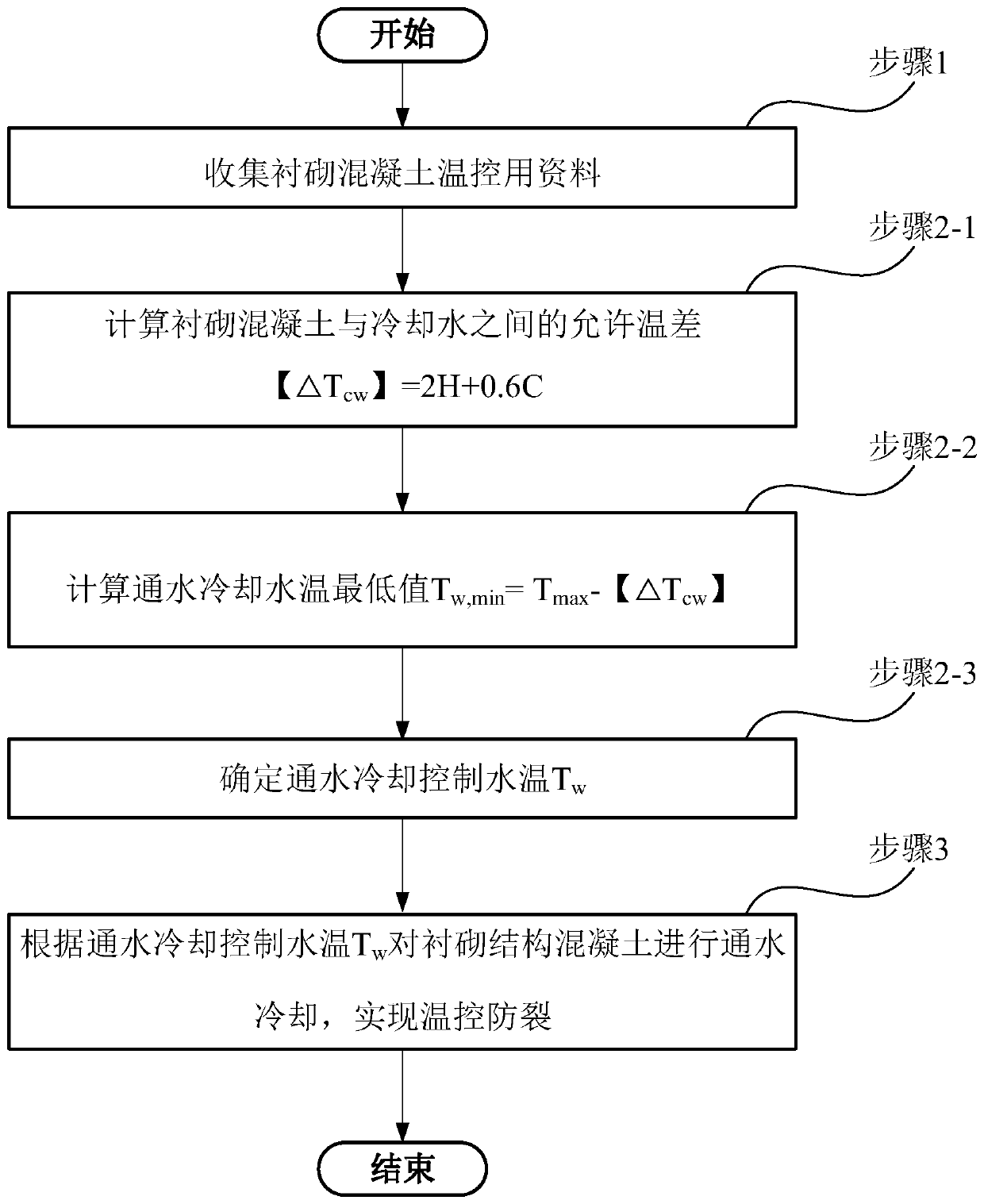

[0109] Such as image 3 As shown, the method for controlling the temperature of the lining structure concrete through water cooling water provided in this embodiment includes the following contents:

[0110] Step 1. Analyze the temperature control data of the lining concrete and determine the water cooling temperature control scheme:

[0111] Step 1-1. Organize and analyze the basic data of lining structure engineering. 2 # The basic information of the lining structure of the fourth unit of the upper flat section of the flood discharge tunnel, including temperature control and crack prevention, water cooling, design ...

Embodiment 2

[0139] 2 # Water cooling of the lining concrete of the fourth unit of the spillway tunnel

[0140] 2 # The 139th unit of the flood discharge tunnel body, the gate-shaped lining, the thickness of the side wall lining is 1.5m, and the circumferential construction joints are set every 12m along the axis of the flood discharge tunnel. The surrounding rock is class IV. The bottom plate and side wall of the lining structure are C 90 40 low heat cement concrete, top arch is C 90 30 Low heat cement concrete, such as Figure 6 shown. The basic temperature control information is the same as above. The design concrete pouring temperature is 18°C, and tap water at room temperature is used for moisturizing and curing for 90 days, and the internal temperature of the concrete is controlled by water cooling. Pour will be poured on November 12th.

[0141] Such as image 3 As shown, the method for controlling the temperature of the lining structure concrete through water cooling water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com