Printing machine ink cleaning equipment for carton packaging production and cleaning process of printing machine ink cleaning equipment

A technology for cleaning equipment and printing machines, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems that ink cannot be recycled, affects production efficiency, and ink chambers are not clean, so as to reduce the amount of sewage generated, Effect of shortening cleaning time and reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

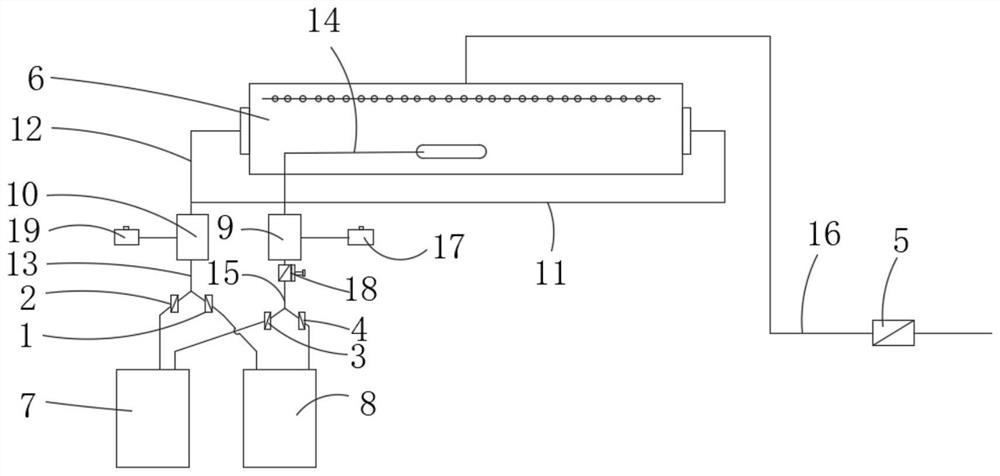

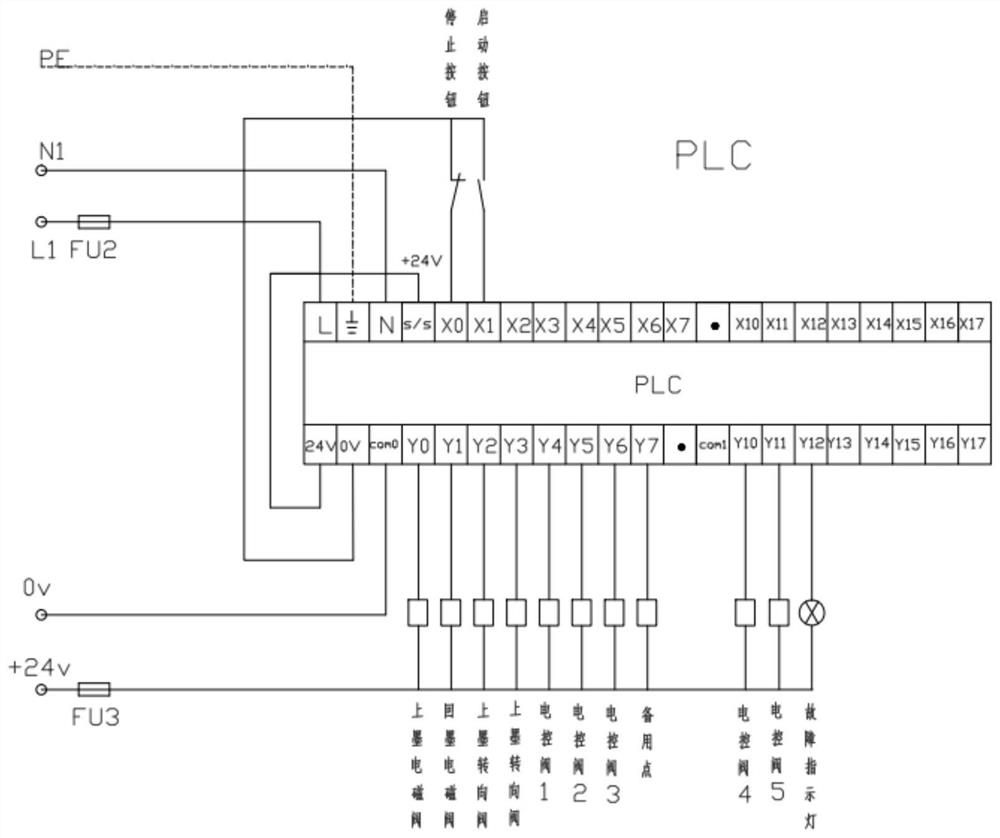

[0034] The present invention provides such figure 1 , 2 , shows a printing machine ink cleaning equipment for carton packaging production, including an ink accumulation chamber 6, a clear water bucket 7, an ink bucket 8, an ink filling pump 9 and an ink return pump 10, and its specific structure is the prior art, here Without going into details, the ink accumulating chamber 6 is a self-contained equipment of the printing machine, which is equipped with two sets of ink return ports and one set of ink filling ports. The clear water bucket 7 is used to store cleaning water and is equipped with a drain pipe, and the ink bucket 8 is used to store ink. , which is equipped with an ink adding port, an ink return pipe is connected between a port of the ink return pump 10 and the ink return port of the accumulated ink chamber 6, and the ink return pipe is composed of a first ink return pipe 11 and a second ink return pipe 12, The first ink return pipe 11 and the second ink return pipe ...

Embodiment 2

[0040] When utilizing the equipment in embodiment 1 to clean the ink accumulation chamber 6 of the printing press, the steps are as follows:

[0041] 1. Shutdown ink return process: the ink filling steering valve 18 is energized and turned to the ink returning direction. At this time, the three pipes of the ink feeding pipe 14, the first ink returning pipe 11 and the second ink returning pipe 12 return the ink at the same time, and the speed is accelerated. The ink tube 14 is changed back to the ink pipeline, and there will be no residual ink in the pipeline;

[0042]2. Add water to dilute the ink and return: After the ink is returned, the PLC automatically controls to enter the process of adding water to dilute and return the ink, and the PLC controls to open the fifth solenoid valve 5, and the ink chamber enters the clear water to dilute the ink and return;

[0043] 3. Circular flushing: After adding water to dilute the ink return time, the PLC controls to close the fifth so...

Embodiment 3

[0047] When utilizing the equipment in embodiment 1 to clean the ink accumulation chamber 6 of the printing press, the steps are as follows:

[0048] 1), one end of the first ink return pipe 11 and the second ink return pipe 12 is communicated with the two ends of the ink accumulation chamber 6, and the other end is communicated with a port of the ink return pump 10, and the ink return pump 10 is connected The other port communicates with the clear water barrel 7 and the ink barrel 8 through the three-way pipe A13 with the first solenoid valve 1 and the second solenoid valve 2;

[0049] 2), connect the ink filling pipe 14 between a port of the ink filling pump 9 and the ink filling port of the ink accumulating chamber 6, then connect the three-way pipe B15 with the third solenoid valve 3 and the fourth solenoid valve 4 with the Another port of the ink pump 9, the clear water barrel 7 and the ink barrel 8 are connected;

[0050] 3), one end of the tap water pipe 16 is communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com