Process for reforming relay heat of heating furnace and equipment thereof

A technology of heating process and heating equipment, which is applied in reforming naphtha, thermal reforming of naphtha, petroleum industry, etc. It can solve problems such as uneven heat transfer of furnace tubes, high pressure of steel structures, waste of steel, etc., and achieve The temperature field of the furnace is uniform, the heating is uniform, and the thermal efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Specific embodiments of the present invention are described with reference to the accompanying drawings.

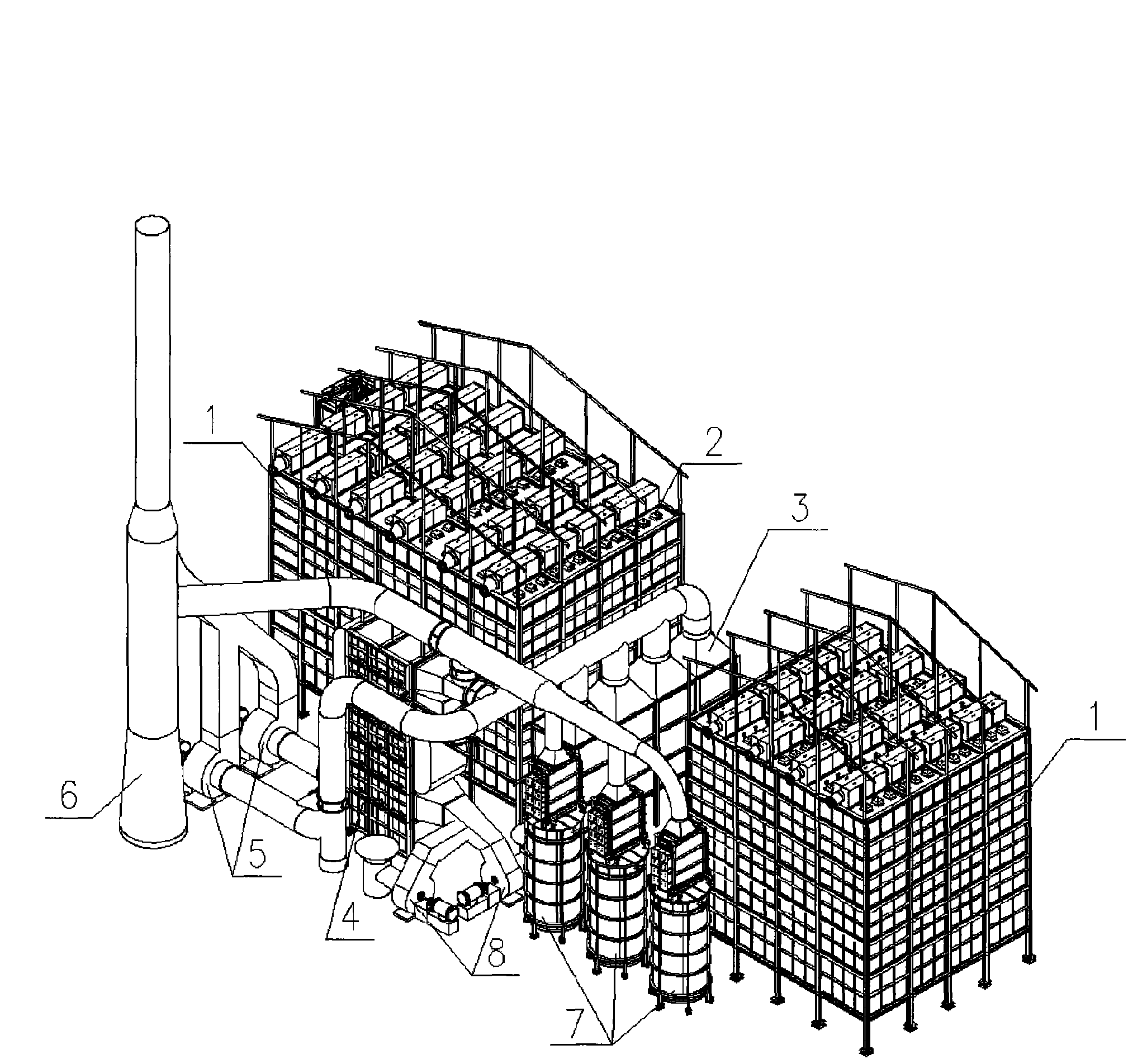

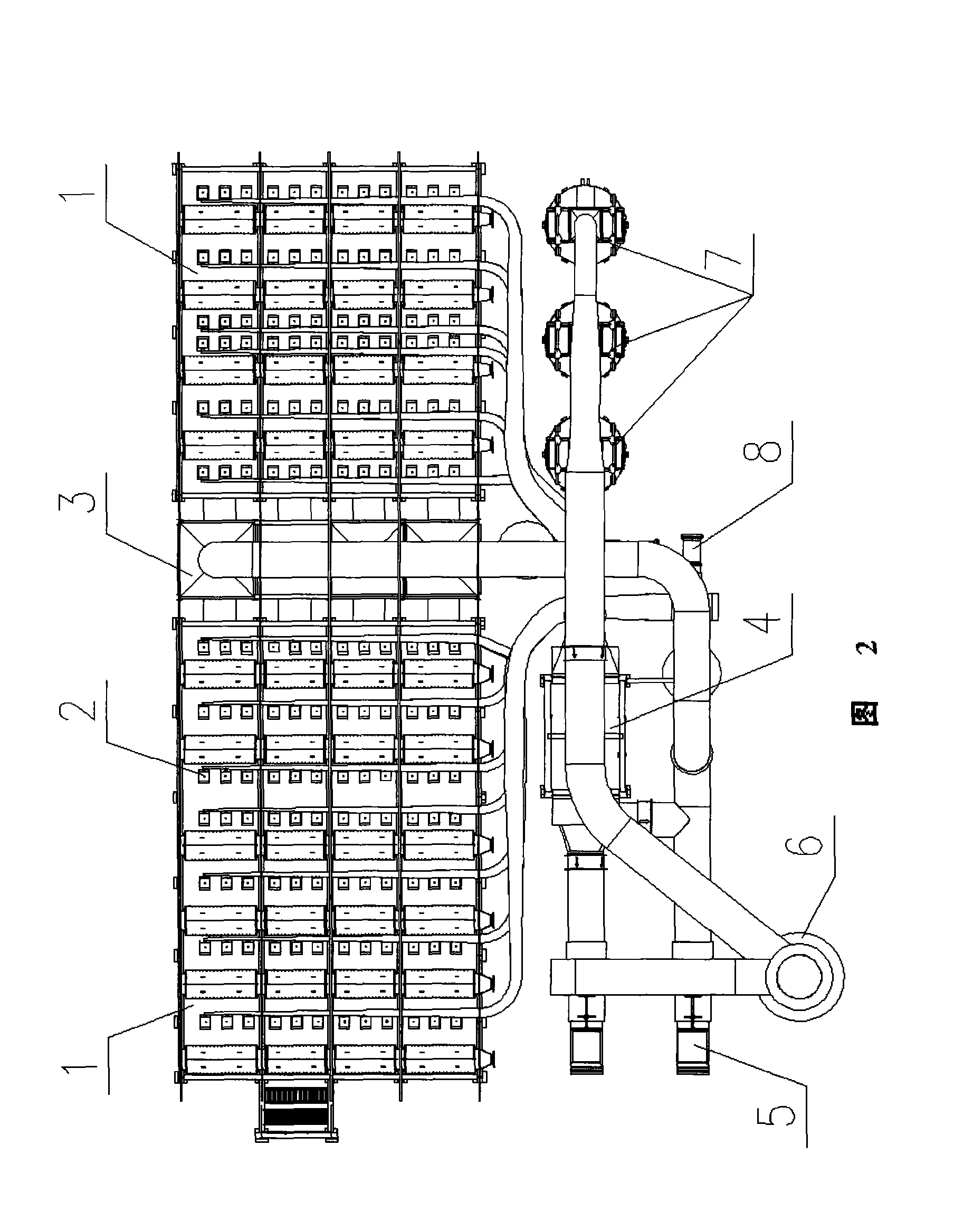

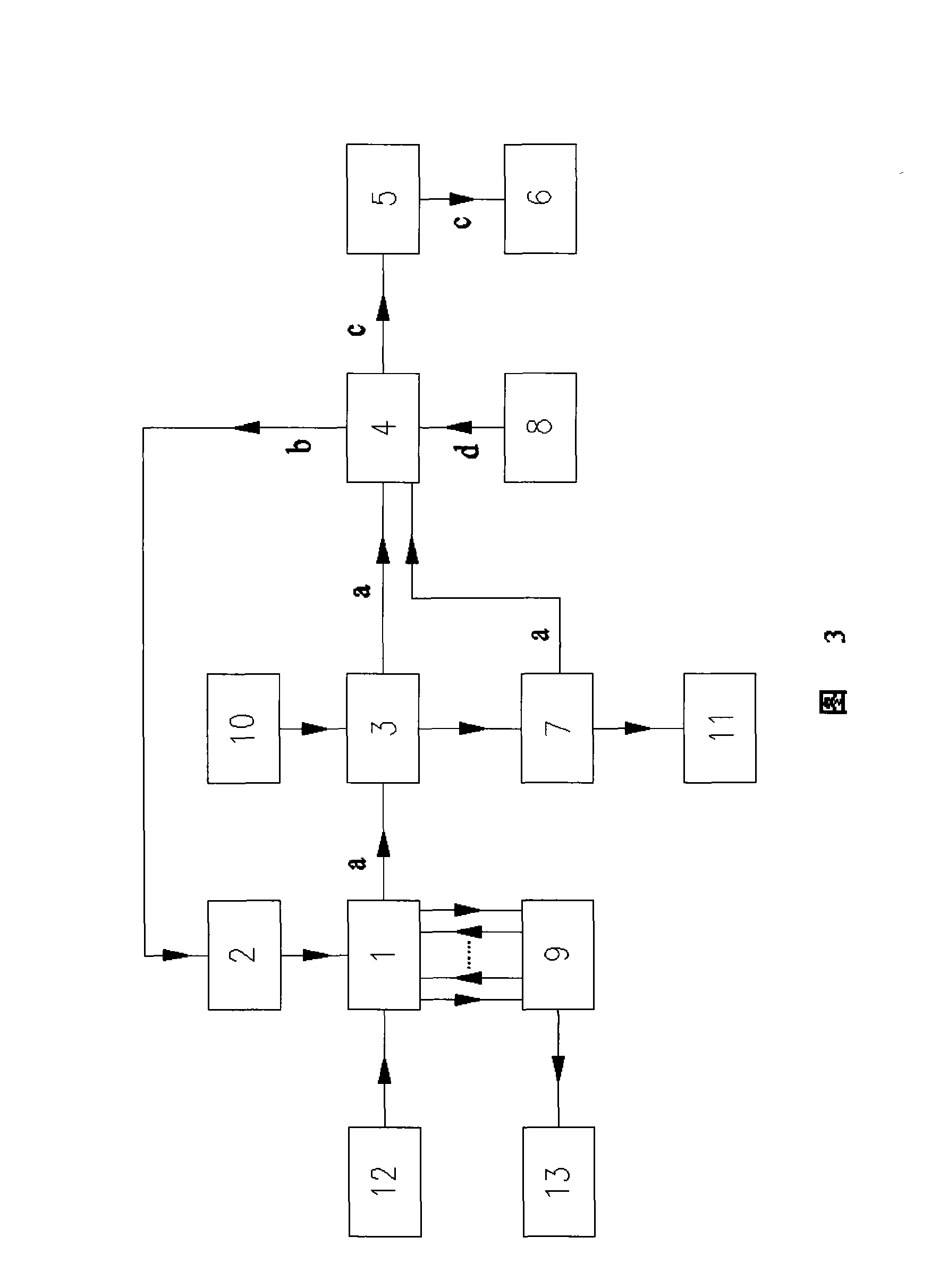

[0067] as attached figure 1 , 2 As shown: the reforming heating furnace according to the present invention is mainly composed of a radiation chamber 1, a ground convection chamber 3, an air preheater 4, a relay heating furnace 7, a blower 8, an induced draft fan 5 and a chimney 6. plumbing connections. A top-fired burner 2 is arranged on the upper part of the radiation chamber. Radiation chamber 1 is a four-in-one combination, that is, one feed heating furnace and three intermediate heating furnaces. Among them, the feed heating furnace, the second intermediate heating furnace and the third intermediate heating furnace are combined into a whole radiation chamber, see the attached figure 1 Mark 1 in the upper left corner; the first intermediate heating furnace is separately set up as a radiation room due to its relatively large heat load, see attached figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com