Preheating method for fuel gas of reforming heating furnace and reforming device

A technology of reforming device and fuel gas, which is applied in the field of reforming device and fuel gas preheating of reforming furnace, which can solve the problems of direct combustion pollution emission, inability to realize fuel gas fine treatment, low temperature flue gas dew point corrosion, etc. , to achieve the effect of solving the problem of excessive sulfur dioxide, solving the problem of dew point corrosion, and reducing the amount of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

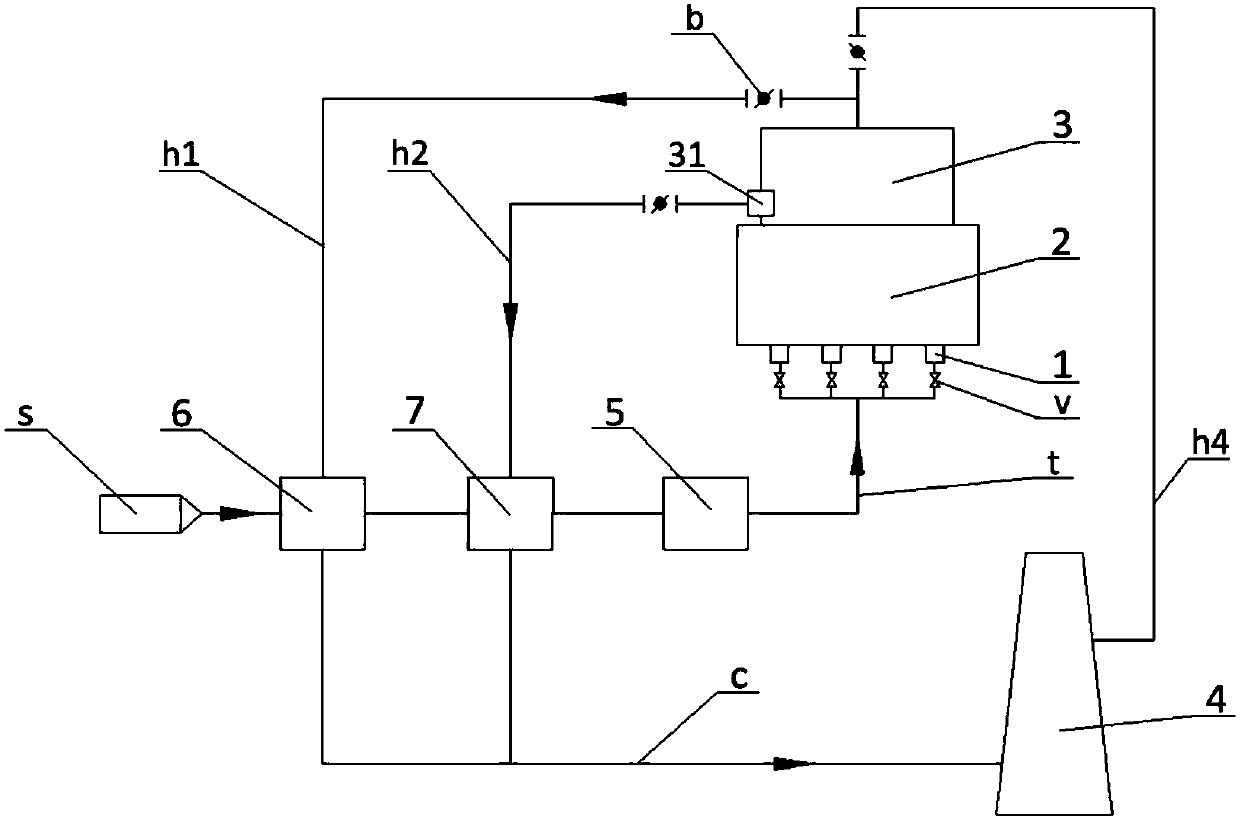

[0029] Such as figure 1 As shown, two stages of fuel gas preheating units are arranged on the fuel gas passage t, which are the first preheater 6 and the second preheater 7 respectively. The flue gas drawn from the top of the convection section 3 passes through the first hot flue h1 into the first preheater 6, and performs a heat exchange with the fuel gas from the fuel gas pipe network s; the position before the flue gas in the convection section 3 enters the waste heat boiler A flue gas outlet 31 in the convection section is provided, and the flue gas drawn from it passes through the second hot flue h2 into the second preheater 7 for secondary heat exchange with the fuel gas. A baffle b is set on the first hot flue h1 to adjust the amount of flue gas passing into the first preheater 6; a similar baffle can also be set on the second hot flue h2 to control the amount of flue gas flowing into the second Flue gas volume of preheater 7. The preheated fuel gas is passed into the...

Embodiment 2

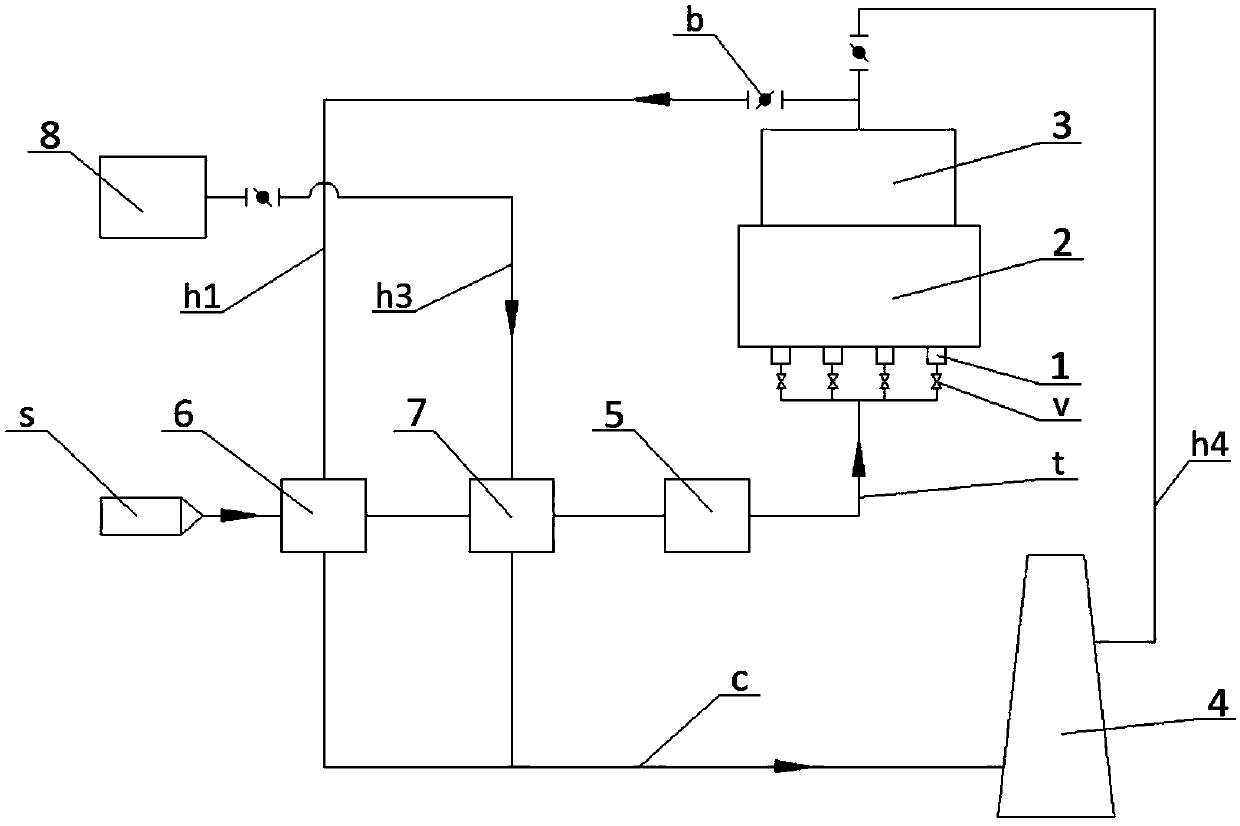

[0031] The difference between the fuel gas preheating method of the reforming furnace in this embodiment and that in Embodiment 1 is that the secondary preheating does not use the waste heat of the high-temperature flue gas in the reforming furnace located at the rear end, but uses the reforming furnace at the rear end The high-temperature flue gas provided by other high-temperature flue gas sources and the fuel gas exchange heat to heat the fuel gas.

[0032] Such as figure 2 As shown, the two-stage fuel gas preheating units installed on the fuel gas passage t are also the first preheater 6 and the second preheater 7, both of which use the waste heat of the flue gas to exchange heat with the fuel gas to achieve fuel gas preheating. The flue gas drawn from the top of the convection section 3 passes through the first hot flue h1 into the first preheater 6, and performs a heat exchange with the fuel gas from the fuel gas pipe network s; other high-temperature flue gas sources 8...

Embodiment 3

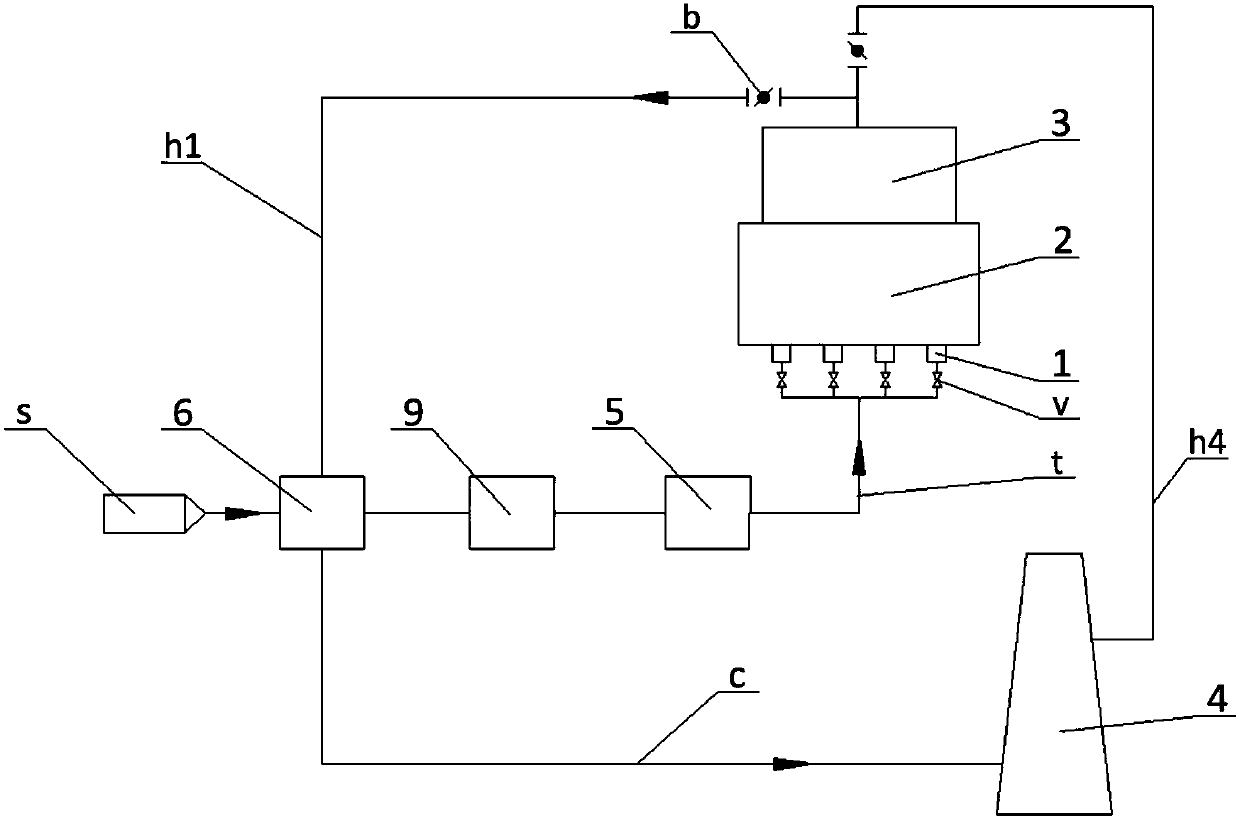

[0034]The difference between the fuel gas preheating method of the reforming furnace in this embodiment and the previous embodiments is that the secondary preheating does not use high-temperature flue gas waste heat, but uses electric heating to directly heat the fuel gas.

[0035] Such as image 3 As shown, a two-stage fuel gas preheating unit is also set on the fuel gas passage t, wherein the primary preheating device is the first preheater 6, and the flue gas is drawn from the top of the convection section 3 to pass through the first hot flue h1 Pass into the first preheater 6 to exchange heat with the fuel gas from the fuel gas pipe network s; the secondary fuel gas preheating unit is an electric heater 9, which will exchange heat with the flue gas in the first preheater 6 The output fuel gas is passed into the electric heater 9 for secondary preheating, the heated fuel gas is passed into the fuel gas finishing treatment unit 5 for finishing treatment, and the processed fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com