Device and method for desulfuration and decyanation treatment of waste liquid generated in vacuum potassium carbonate desulfurization process

A technology of vacuum potassium carbonate and desulfurization process, which is applied in the direction of gaseous effluent wastewater treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc. Good utilization method, difficult operation and control, etc., to achieve the effect of low cost of chemicals and operation, strong engineering application value, and reduction of sulfur cyanide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

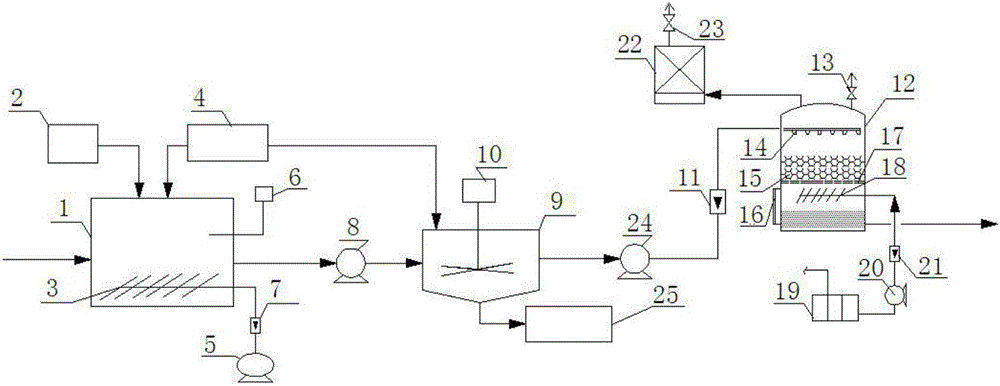

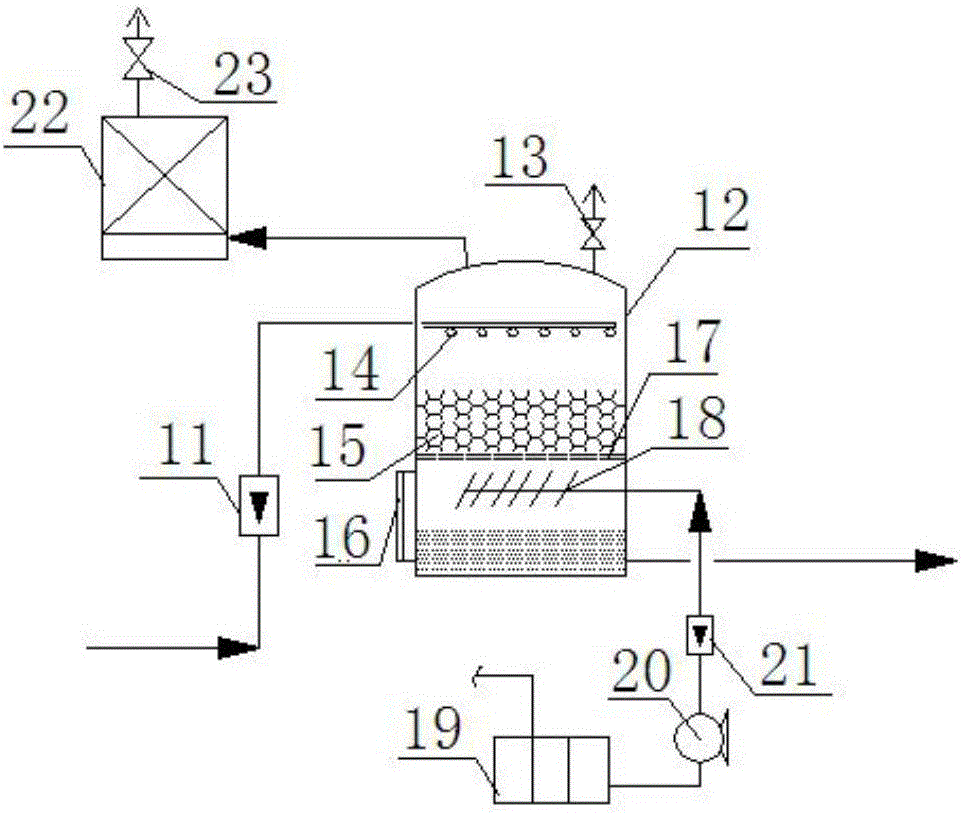

[0043] Embodiment 1: as figure 1 A treatment device for desulfurization and decyanation of waste liquid in the vacuum potassium carbonate desulfurization process shown, its equipment setting and implementation steps are all the same as above, wherein: the waste liquid is 1L,

[0044] (1) Pretreatment: The dosage of ferrous sulfate in reaction tank 1 is 180g / L, the dosage of coagulant is 0.2g / L, the reaction temperature is 15°C, and the reaction gas-water ratio is 3:1. The hydraulic retention time is 2 hours. After aeration and stirring, a large amount of black mixture is pumped to the sedimentation tank 9 for mud-water separation. The rotation speed of the mixer 10 in the sedimentation tank 9 is 50rpm, the hydraulic retention time in the sedimentation tank 9 is 10h, the sludge at the bottom of the sedimentation tank 9 is pumped to the sludge filter press system, and the mud cake is sent to the coal yard for coal blending and coking. After the reaction, the supernatant in the ...

Embodiment 2

[0046] Embodiment 2: as figure 1 A treatment device for desulfurization and decyanation of waste liquid of a vacuum potassium carbonate desulfurization process shown, its equipment and implementation steps are the same as in Example 1, except for the following settings and steps:

[0047] (1) In pretreatment, the dosage of ferrous sulfate in reaction tank 1 is 90g / L, the dosage of coagulant is 0.5g / L, the reaction temperature is 25℃, and the reaction gas-water ratio is 5: 1. The hydraulic retention time is 3h; the rotational speed of the mixer 10 in the sedimentation tank 9 is 60rpm, and the hydraulic retention time in the sedimentation tank 9 is 10h. After the reaction finishes, get the supernatant in the sedimentation tank 9 to detect, and measure S 2- The removal rate of ions was 72.1%, and the cyanide ion CN - The removal rate is 36.9%.

[0048] (2) In the advanced treatment, the gas-water ratio in the ozone generator 19 is 2:1, and the hydraulic retention time of the s...

Embodiment 3

[0049] Embodiment 3: as figure 1 A treatment device for desulfurization and decyanation of waste liquid of a vacuum potassium carbonate desulfurization process shown, its equipment and implementation steps are the same as in Example 1, except for the following settings and steps:

[0050] (1) In pretreatment, the dosage of ferrous sulfate in reaction tank 1 is 45g / L, the dosage of coagulant is 0.5g / L, the reaction temperature is 40℃, and the reaction gas-water ratio is 7:1 , the hydraulic retention time is 5h; the rotational speed of the mixer 10 in the sedimentation tank 9 is 150rpm, and the hydraulic retention time in the sedimentation tank 9 is 20h. After the reaction is over, take the supernatant in the sedimentation tank 9 for detection, and measure the sulfur ion S in the waste liquid. 2- The removal rate of cyanide ion CN was 57.9%. - The removal rate is 31.2%.

[0051] (2) In advanced treatment, the gas-water ratio in the ozone generator 19 is 3:1, and the hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com