Deep processing method and device of cold rolling oil-containing wastewater

A technology for advanced treatment and wastewater, applied in the field of water treatment, can solve the problems of reducing COD emissions per ton of steel, and achieve the effects of reducing COD emissions, low production and operation costs, and easy operation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

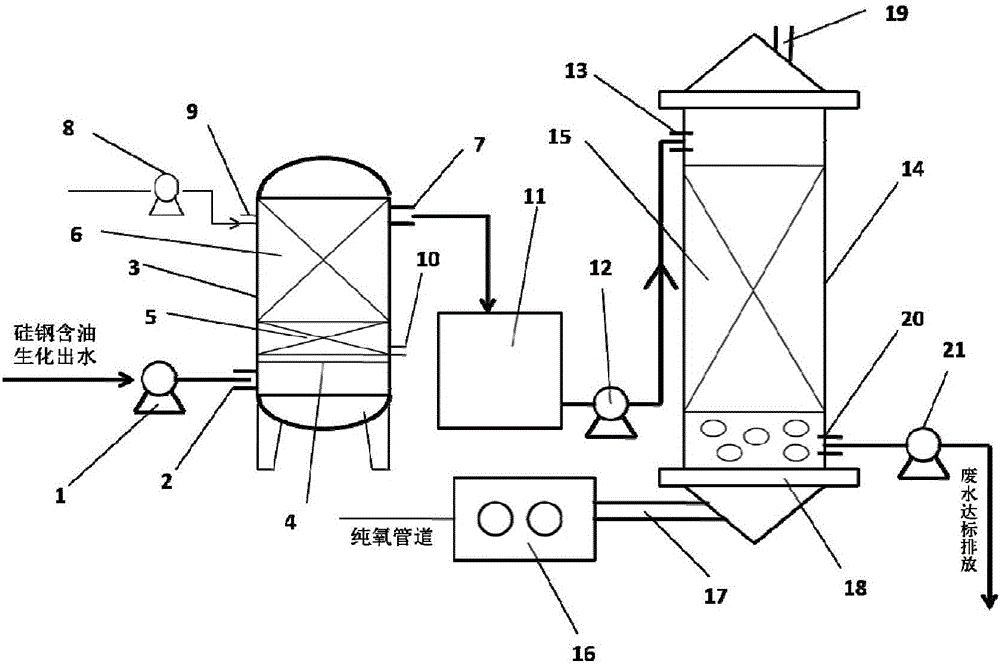

[0031] The present invention is a treatment process system for the depth of cold-rolled oily waste water, including a primary water inlet pump, a filter water inlet, a multi-media filter, a water distributor, a ceramsite filling area, a water slag filling area, a filter outlet, Backwash pump, backwash water inlet, backwash water outlet, intermediate pool, secondary water inlet pump, catalytic tower water inlet, ozone catalytic tower, diatomaceous earth ozone catalyst, ozone generator, ozone pipeline and air inlet, ozone diffusion Device, ozone quencher and gas outlet, outlet of catalytic tower, drainage pump.

[0032] What the present invention adopts is the biochemical effluent of cold-rolled oily waste water. 630~1670mg / L.

[0033] The cold-rolled oily biochemical effluent enters the multi-media filter from the filter inlet through the pipeline through the first-stage water inlet pump. The water distributor in the filter has an aperture of 25-75mm, and then passes through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com