Smelting method of grain oriented silicon steel alloyed in rh furnace

A technology of grain-oriented silicon steel and smelting method, which is applied in the smelting field of grain-oriented silicon steel to achieve the effects of stable alloy yield, reduction of alloy oxidation loss, and reduction of fine-tuning times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

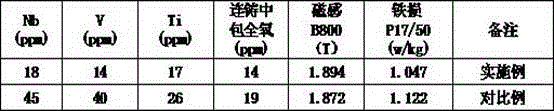

[0024] Example 1 (for general grain-oriented silicon steel)

[0025] 1) Carry out converter smelting and tapping, and the tapping temperature is controlled at 1680-1688°C;

[0026] 2) A slag stopper is used to stop the slag at the end of the converter tapping, and the thickness of the slag layer on the surface of the molten steel after the steel tapping is measured is 37mm;

[0027] 3) RH refining: After 3 minutes of decarburization, according to the oxygen content in molten steel, add aluminum shot and bauxite for deoxidation and slagging, the amount of aluminum added is 7 times the weight percentage of oxygen, and the calculated addition The amount is 0.437kg / t, and bauxite is added according to the amount of 1.0kg / t; after the addition of aluminum pellets and bauxite, it circulates for 2 minutes, and then carries out alloying according to the designed amount of addition until it reaches the set value of the composition;

[0028] 4) Casting into a billet and performing subs...

Embodiment 2

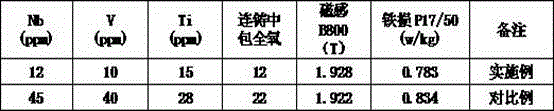

[0031] Example 2 (for general grain-oriented silicon steel)

[0032] 1) Carry out converter smelting and tapping, and the tapping temperature is controlled at 1665-1670°C;

[0033] 2) A slag stopper is used to stop the slag at the end of the converter tapping, and the thickness of the slag layer on the surface of the molten steel is measured to be 42mm after the tapping is completed;

[0034] 3) RH refining: after decarburization for 5 minutes, according to the oxygen content in molten steel, add aluminum shot and bauxite for deoxidation and slagging, the amount of aluminum added is 7 times the weight percentage of oxygen, and the calculated addition The amount is 0.385kg / t, and the bauxite is added according to the amount of 1.15kg / t; after the aluminum shot and bauxite are added, the cycle is 2.5min, and then the alloying is carried out according to the designed addition amount until the composition setting value is reached;

[0035] 4) Casting into a billet and performing ...

Embodiment 3

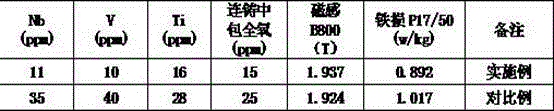

[0038] Example 3 (high temperature and high magnetic induction grain-oriented silicon steel, namely Hi-B)

[0039]1) Carry out converter smelting and tapping, and the tapping temperature is controlled at 1670-1675°C;

[0040] 2) A slag stopper is used to stop the slag at the end of the converter tapping, and the thickness of the slag layer on the surface of the molten steel is measured to be 35mm after the tapping is completed;

[0041] 3) RH refining: After 3.5 minutes of circulating decarburization, according to the oxygen content in molten steel, add aluminum shot and bauxite for deoxidation and slagging, the amount of aluminum added is 8 times the weight percentage of oxygen, and the calculation The addition amount is 0.256kg / t, and the bauxite is added according to the amount of 1.05kg / t; after the addition of aluminum pellets and bauxite, it circulates for 3 minutes, and then carries out alloying according to the designed addition amount until the composition setting val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com