Preparation method of low-cost medium carbon steel spherical powder for 3D printing

A 3D printing and spherical powder technology, applied in metal processing equipment, transportation and packaging, etc., to achieve the effect of optimizing process parameters, reducing the number and size of inclusions, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

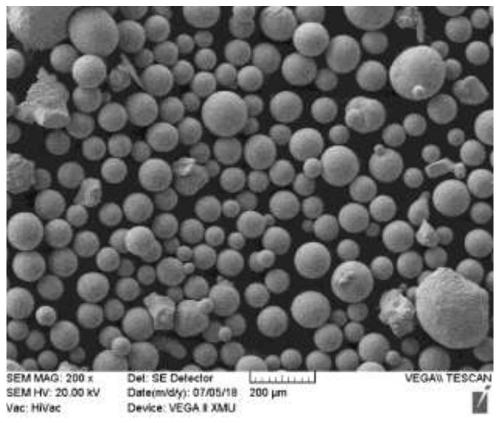

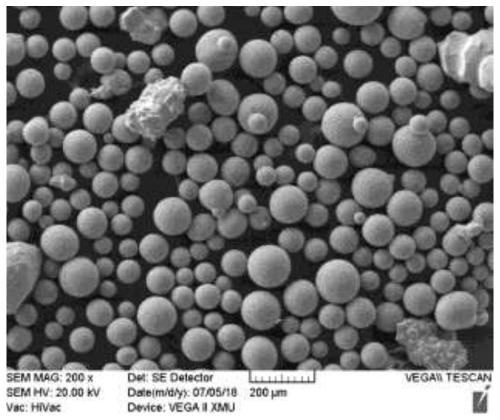

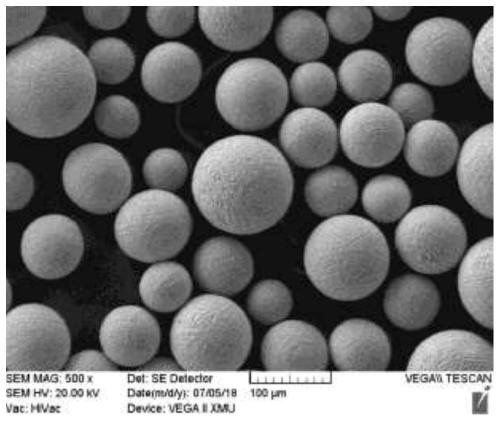

Image

Examples

Embodiment 1

[0030] The specific steps of the invention of a medium-carbon steel metal spherical powder for 3D printing:

[0031] S1: Proportion medium carbon steel according to C: 0.43%; Mn: 0.58%; Si: 0.18%; Cr: 0.25%;

[0032] S2: The medium-carbon steel alloy rod smelted according to S1 is subjected to fine turning processing to remove the black oxide scale on the surface, and the powder meets the requirements of plasma rotating electrode atomization to obtain powder. The density of the alloy rod reaches more than 99%, and the surface is not obvious. Defects, the diameter of the processed medium carbon steel alloy bar is 70mm, the length is 230mm, the circular runout is 0.02mm, the straightness deviation is 0.86mm / m, and the roughness is 1.2μm;

[0033] S3: The electrode rod processed by S2 is put into the plasma rotary electrode powder making machine to form a new dynamic sealing structure, and then vacuumized and filled with protective gas: argon and helium mixed gas, so that the pre...

Embodiment 2

[0037] Concrete steps for the invention of a medium-carbon steel metal spherical powder for 3D printing:

[0038] S1: According to C: 0.43%; Mn: 0.58%; Si: 0.18%; Cr: 0.25%; Ni: 0.24%;

[0039]S2: The medium-carbon steel alloy rod smelted according to S1 is subjected to fine turning processing to remove the black oxide scale on the surface, and the powder meets the requirements of plasma rotating electrode atomization to obtain powder. The density of the alloy rod reaches more than 99%, and the surface is not obvious. Defects, the diameter of the processed medium carbon steel alloy bar is 70mm, the length is 230mm, the circular runout is 0.02mm, the straightness deviation is 0.86mm / m, and the roughness is 1.2μm

[0040] S3: The electrode rod processed by S2 is put into the plasma rotary electrode powder making machine to form a new dynamic sealing structure, and then vacuumized and filled with protective gas: argon and helium mixed gas, so that the pressure in the powder makin...

Embodiment 3

[0044] The specific steps of the invention of a medium-carbon steel metal spherical powder for 3D printing:

[0045] S1: According to C: 0.43%; Mn: 0.58%; Si: 0.18%; Cr: 0.25%; Ni: 0.24%;

[0046] S2: The medium-carbon steel alloy rod smelted according to S1 is subjected to fine turning processing to remove the black oxide scale on the surface, and the powder meets the requirements of plasma rotating electrode atomization to obtain powder. The density of the alloy rod reaches more than 99%, and the surface is not obvious. Defects, the diameter of the processed medium carbon steel alloy bar is 80mm, the length is 240mm, the circular runout is 0.02mm, the straightness deviation is 0.86mm / m, and the roughness is 1.2μm

[0047] S3: The electrode rod processed by S2 is put into the plasma rotary electrode powder making machine to form a new dynamic sealing structure, and then vacuumized and filled with protective gas: argon and helium mixed gas, so that the pressure in the powder m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com