Deoxidation method of low-silicon steel by utilization of silicon alloys

A technology of silicon alloy and low silicon steel, which is applied in the field of silicon alloy deoxidation for low silicon steel, can solve the problems of increasing silicon in molten steel, and achieve the effect of reducing cost and reducing the number of inclusions

Active Publication Date: 2013-09-04

ANGANG STEEL CO LTD

View PDF3 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since ultra-low carbon steel requires less silicon (≤0.030%), the use of silicon alloys for deoxidation can easily lead to silicon increase in molten steel, so no one has tried to use silicon alloys as deoxidizers for converter steelmaking.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

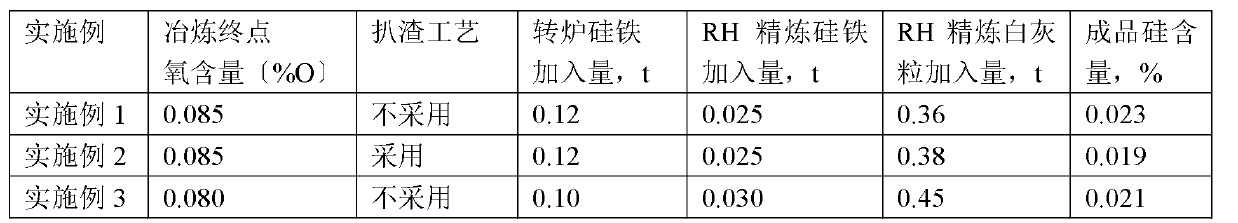

Embodiment 1

[0032] See Table 2 for the comparison of the process effects of using ferrosilicon deoxidation and AlMnFe alloy deoxidation in Example 1.

[0033] Table 2

[0034] project

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

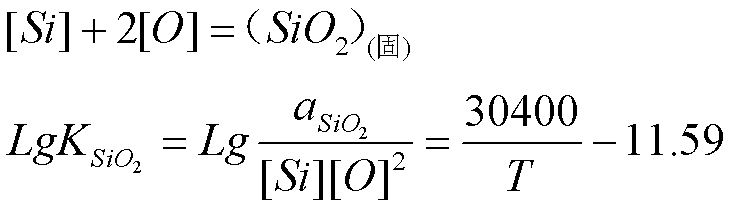

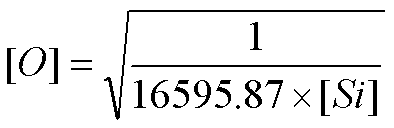

The invention relates to the technical field of steel-making, especially to a deoxidation method of low-silicon steel by the utilization of silicon alloys. In the production process route of converter-RH vacuum refining-slab continuous casting, silicon alloys are respectively added as a deoxidizer during the converter tapping process and RH treatment process so as to remove excess oxygen in ultra-low carbon steel in the converter area and excess oxygen left after RH decarburization. The method provided by the invention specifically comprises the following steps: 1) boiling and tapping during the converter process, and carrying out deoxidation by adding ferrosilicon during the tapping process; 2) carrying out pre-deoxidation by the use of ferrosilicon during the RH treatment process; and 3) adding aluminium for final deoxidation after RH decarburization, calculating critical oxygen content according to 0.045%, and carrying out ingredient adjustment. In comparison with the prior art, the invention has the following beneficial effects: by the use of silicon alloys (ferrosilicon) to remove excess oxygen, the content of silicon in molten steel can be controlled below 0.030%; and in the case of realizing the same deoxidation effect, inclusion quantity of Al2O3 in a casting blank is minimized, and deoxidation alloy cost is reduced.

Description

technical field [0001] The invention relates to the technical field of steelmaking, in particular to a method for deoxidizing low-silicon steel by using a silicon alloy. Background technique [0002] In the production of ultra-low carbon steel such as cold-rolled IF steel and silicon steel in the converter, in order to ensure the oxygen content requirements and strict phosphorus content requirements for deep decarburization of RH, the carbon content at the end of smelting is controlled at a low level. The station adopts the method of feeding aluminum wire to control the oxygen content to between 450~650ppm. [0003] Oxygen in the steel at the end of converter smelting is the main source of oxide inclusions. Whether it is to produce ultra-low carbon steel or low-carbon steel, aluminum alloys are generally used to adjust the oxygen content, resulting in Al in slag 2 o 3 Higher, the cleanliness of the steel decreases, resulting in Al in the slab 2 o 3 The relative increase ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C7/06

Inventor 李伟东袁皓杨辉舒耀王成青赵晨光王向辉

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com