Pressurizing casting device and method for automobile hub

A technology for casting equipment and automobile wheel hubs, which is applied in the field of automobile wheel hub manufacturing, can solve the problems of low gravity casting quality rate and high production cost of pressure casting, and achieve the effect of improving the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

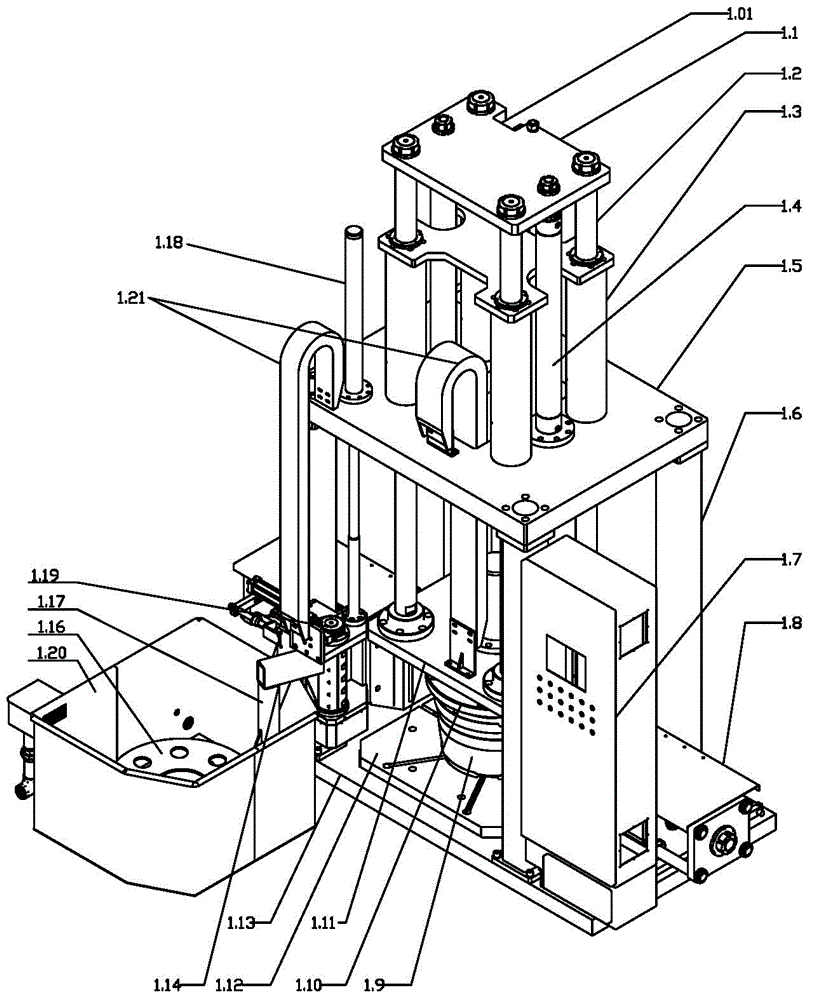

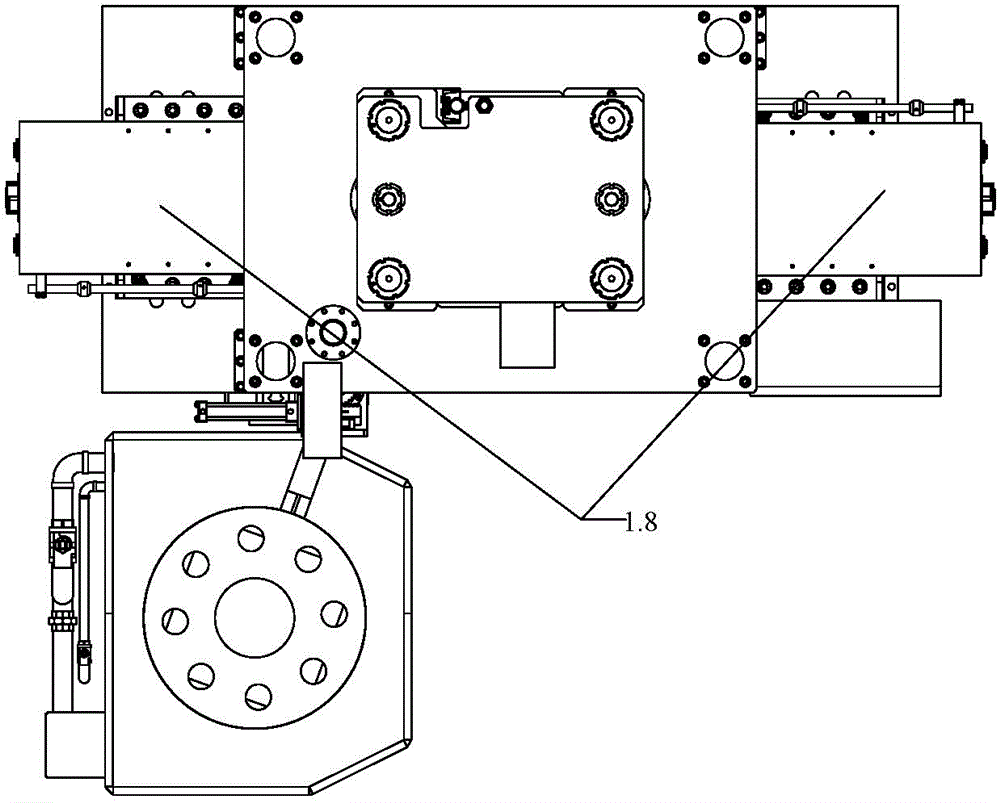

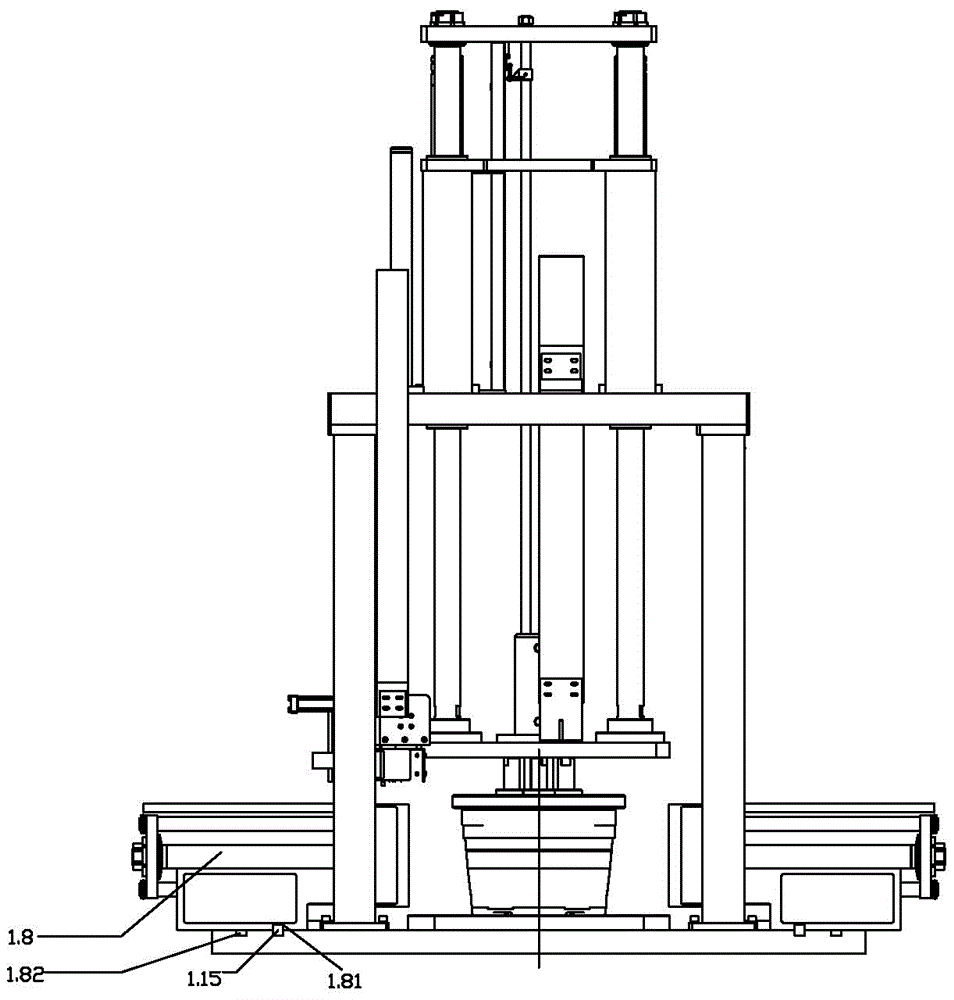

[0077] The pressurized casting equipment for automobile wheel hubs of the present invention comprises a main body, a casting mold, a movable slide table, a mold clamping oil cylinder, a side mold clamping mechanism, a pressure boosting mechanism and a mold cooling system.

[0078] Such as figure 1 As shown, the main body is formed by fixedly connecting the upper seat plate 1.5 and the lower seat plate 1.13 through the column 1.6.

[0079] Such as Figure 5 combine figure 1 As shown, the casting mold: includes upper mold 3.3, bottom mold 3.10, side mold 3.1 and side gating system 3.6. Such as Figure 4 The shown upper mold 3.3 is fixedly connected with an upper mold fixing base 2.7 by screws 2.6. Such as Figure 5 The shown bottom mold 3.10 is fixedly installed on the lower mold base 1.12 through the mold foot 3.8, and the lower mold base 1.12 is fixedly installed on the lower base plate 1.13. The center of the bottom mold 3.10 is provided with an iron core 3.13, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com