Vacuum low-pressure casting forming device for titanium alloy component

A vacuum low-pressure casting forming technology, which is applied in the field of titanium alloy anti-gravity casting, casting and casting equipment, can solve problems such as inability to use castings for production, limited suction casting force, alloy liquid filling power and low solidification and feeding pressure, etc. To achieve the effect of improving the filling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

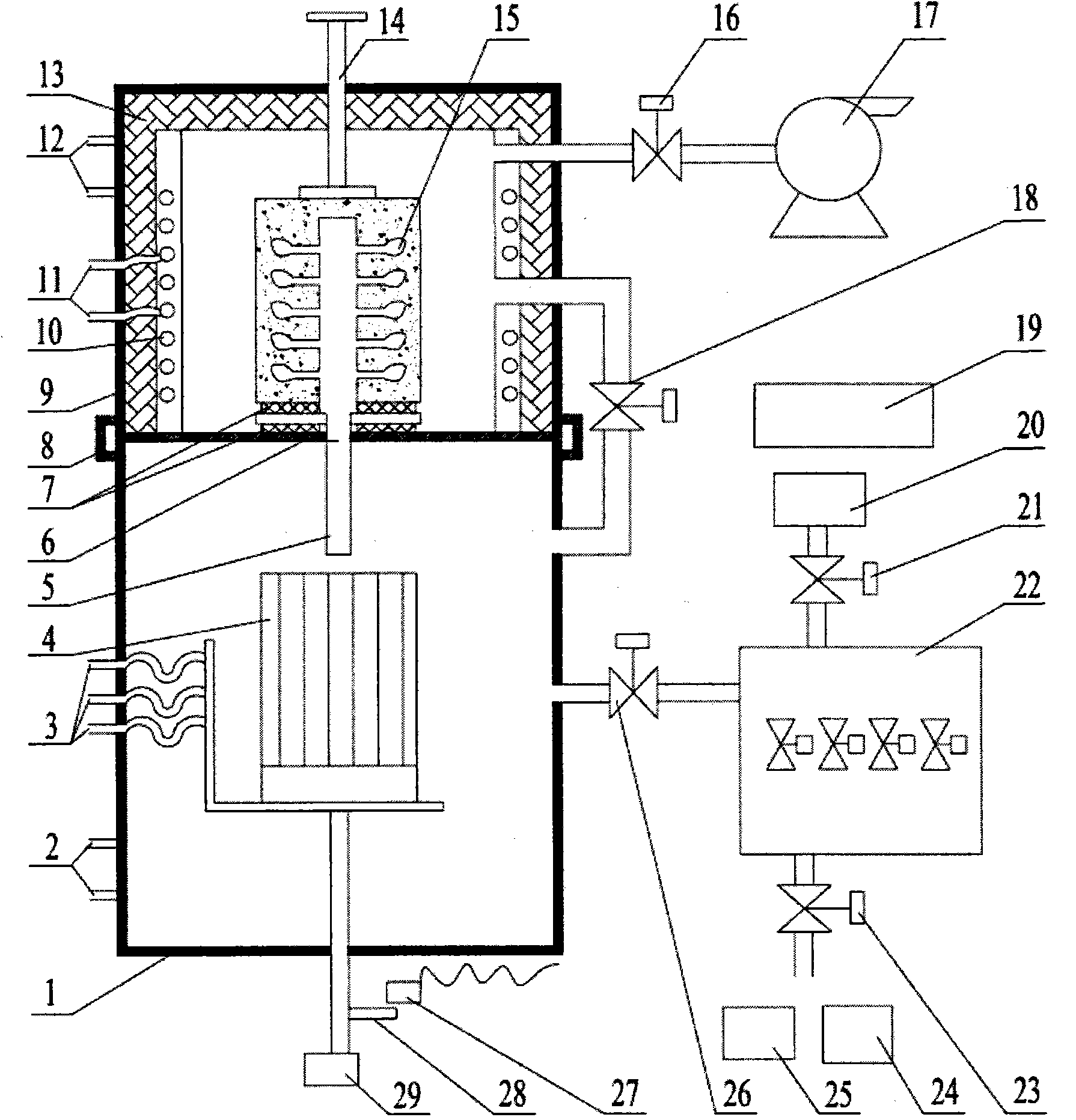

[0012] This embodiment is a vacuum low pressure casting forming device for titanium alloy components

[0013] like figure 1 As shown, a vacuum low-pressure casting forming device for titanium alloy components is mainly composed of a lower chamber 1, a lower chamber cooling water inlet and outlet 2, a copper crucible electrode access point 3, a water-cooled copper crucible 4, a liquid riser 5, a middle partition 6, Gasket 7, locking and sealing mechanism 8, upper chamber 9, resistor 10, electrode interface 11, upper chamber cooling water inlet and outlet 12, insulation layer 13, mold shell locking mechanism 14, casting mold shell 15, upper chamber inlet and outlet Gas solenoid valve 16, vacuum system 17, upper and lower chamber communication electric control stop valve 18, computer control system 19, protective gas source system 20, gas source electric control stop valve 21, digital combination valve 22, exhaust electric control stop valve 23. Induction power supply 24, coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com