Casting method for directional solidification column crystal and single-crystal blade

A single crystal blade, directional solidification technology, applied in the field of investment precision casting, can solve the problem of thin edge plate looseness, etc., and achieve the effect of improving the feeding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment the present invention is described in further detail:

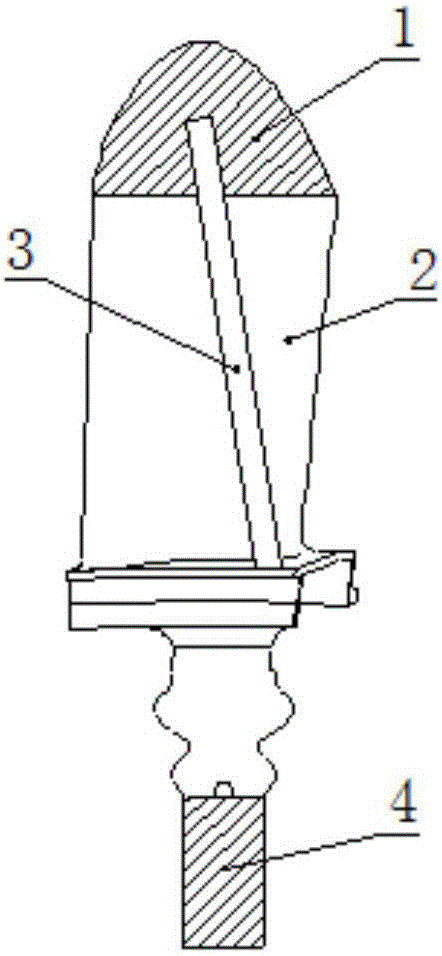

[0033] Such as figure 1 As shown, when the blade wax model is trimmed and assembled, one end of the process feeding rib is bonded to the inner gate of the upper end of the blade, basically parallel to the blade body, and the gap between the blade body and the blade body is more than 8mm, and the other end is bonded to the corner of the edge plate , The position determination principle is that at the corner of the edge plate farthest from the blade body, and at the connection with the edge plate, a 1-2mm cutting section should be reserved. The width and thickness of the cutting section can be greater than or equal to the process feeding rib. Process feeding bars can be cylindrical process bars with a diameter of about Φ3mm, and flat process feed bars with a thickness of 0.5 mm to 1 mm and a width of 3 mm to 6 mm. The process feeding ribs cannot be straightened and tight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com