Sand-lined metal mold casting technology for high-manganese steel liner plate

A metal mold sand-coated, high-manganese steel lining technology, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of high-manganese steel lining shrinkage, low density, coarse grains, etc. , to achieve the effect of grain refinement, shrinkage cavity defect reduction and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

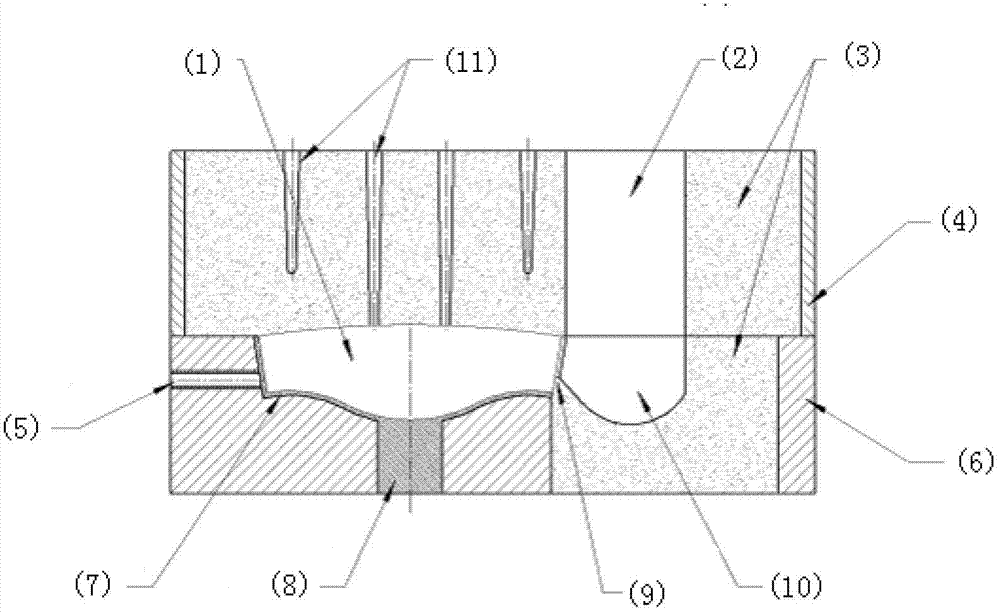

[0025] A metal mold sand-covered casting process for a high manganese steel liner, comprising the following steps:

[0026] (1) Design and processing of metal molds

[0027] According to the shape of the casting, the shape of the inner and outer metal molds is designed, gray cast iron or nodular cast iron is used for molding, and the metal mold wall thickness is controlled at 15mm; the whole mold is composed of the upper box of the water glass sand mold and the lower box of the metal mold; the upper box There is a pouring riser, and there are ventilation holes on the sodium silicate sand mold. The spacing of the ventilation holes is 80mm, some of which lead to the cavity, and some of which do not lead to the cavity; the lower box is equipped with a riser area, and a riser seat is installed in the riser area , the riser seat is surrounded by water glass sand mold, the riser seat corresponds to the riser, and the riser seat is connected with the cavity of the linin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com