Dynamic nanochannel and preparing and testing methods thereof

A nano-channel and dynamic technology, applied in nanotechnology, measuring devices, material analysis through electromagnetic means, etc., can solve the problem of non-adjustable aperture and achieve the effect of guaranteed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

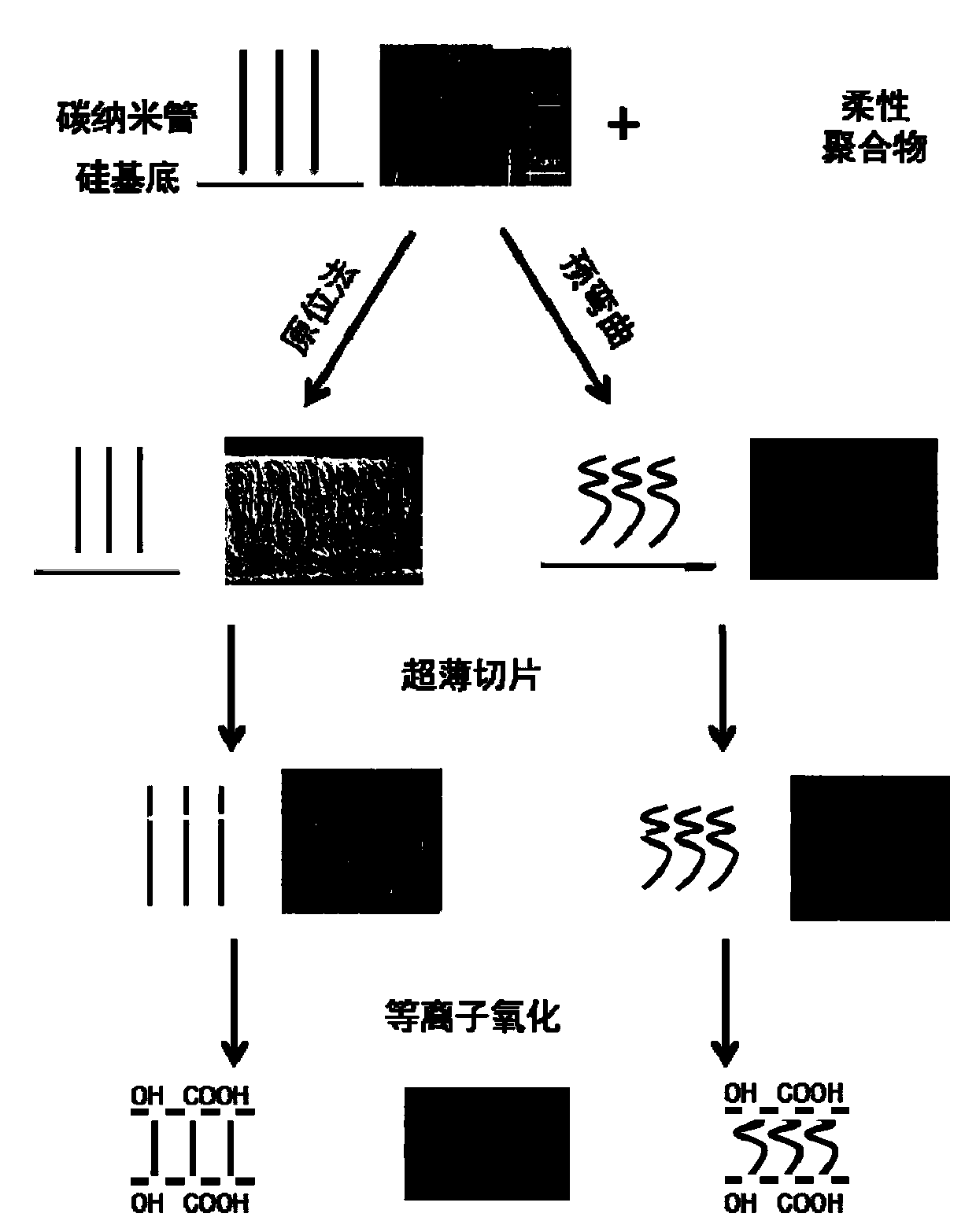

[0038] In the first step, toluene is used as the carbon source, ferrocene is used as the catalyst, and a 4% ferrocene / toluene solution is configured, and the floating-assisted catalytic method (FCCVD) is used to grow and prepare wide-diameter tubes (outer diameter ~ 80nm) at 740°C. , inner diameter ~ 8nm), high crystallinity (I G / D ≈2.51), high density (0.17g / cm3 ), highly controllable (20-1000 μm) carbon nanotube arrays.

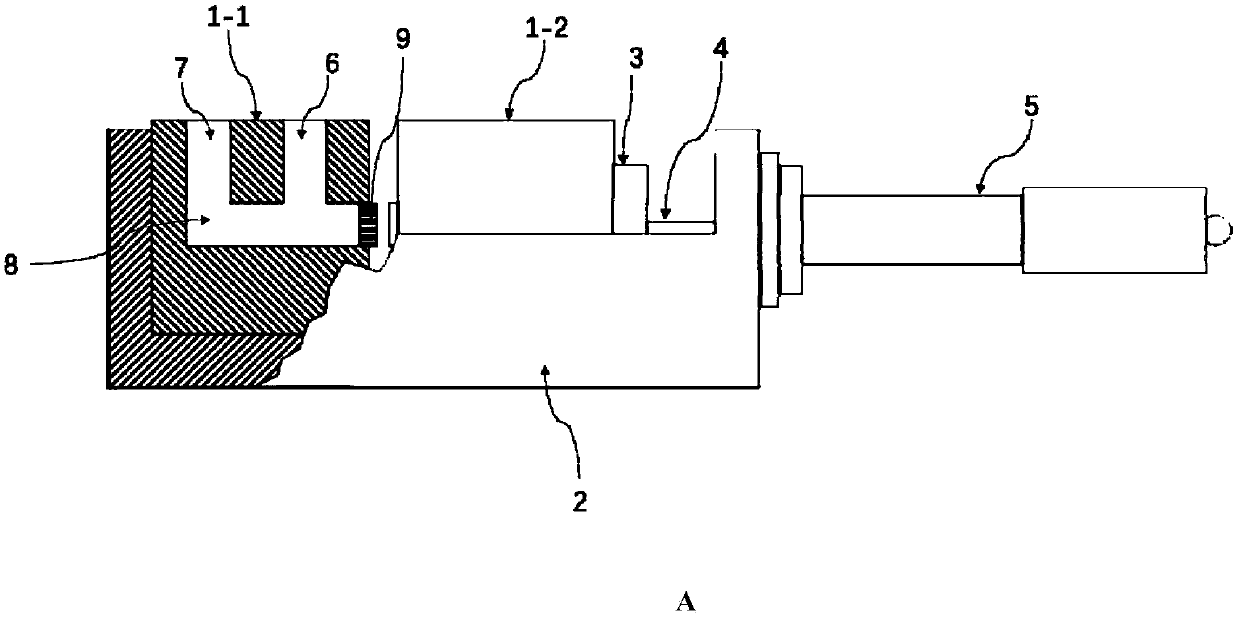

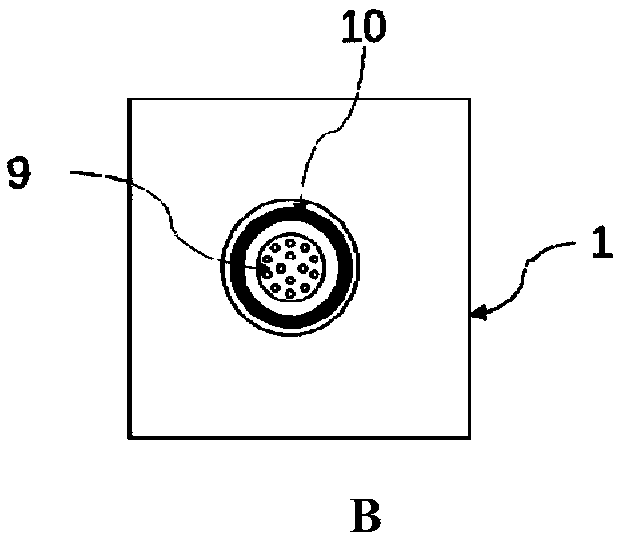

[0039] In the second step, the components A and B of polydimethylsiloxane (PDMS) are mixed uniformly at a ratio of 10:1, degassed for 30 minutes, and dropped onto the surface of the in-situ or pre-bent carbon nanotube array with a straw After the array is completely soaked, let it stand for 30 minutes, and set the spin coating program ①500r-20s; ②3000r-40s to remove excess resin. Curing at 70° C. for 3 hours, peeling off the surface of the substrate after complete curing, polishing the surface to expose the ends of the carbon tubes, and slicing the film wi...

Embodiment 2

[0042] In the first step, toluene is used as the carbon source, ferrocene is used as the catalyst, and a 4% ferrocene / toluene solution is configured, and the floating-assisted catalytic method (FCCVD) is used to grow and prepare wide-diameter tubes (outer diameter ~ 80nm) at 740°C. , inner diameter ~ 8nm), high crystallinity (I G / D ≈2.51), high density (0.17g / cm 3 ), highly controllable (20-1000 μm) carbon nanotube arrays.

[0043] In the second step, the components A and B of polydimethylsiloxane (PDMS) are mixed uniformly at a ratio of 10:1, degassed for 30 minutes, and dropped onto the surface of the in-situ or pre-bent carbon nanotube array with a straw After the array is completely soaked, let it stand for 30 minutes, and set the spin coating program ①500r-20s; ②3000r-40s to remove excess resin. Curing at 70°C for 3 hours, peeling off the substrate surface after complete curing, polishing the surface to expose the carbon tube ends, and cutting the film with an ultramicr...

Embodiment 3

[0046] In the first step, toluene is used as the carbon source, ferrocene is used as the catalyst, and a 4% ferrocene / toluene solution is configured, and the floating-assisted catalytic method (FCCVD) is used to grow and prepare wide-diameter tubes (outer diameter ~ 80nm) at 740°C. , inner diameter ~ 8nm), high crystallinity (I G / D ≈2.51), high density (0.17g / cm 3 ), highly controllable (20-1000 μm) carbon nanotube arrays.

[0047] In the second step, the components A and B of polydimethylsiloxane (PDMS) are mixed uniformly at a ratio of 10:1, degassed for 30 minutes, and dropped onto the surface of the in-situ or pre-bent carbon nanotube array with a straw After the array is completely soaked, let it stand for 30 minutes, and set the spin coating program ①500r-20s; ②3000r-40s to remove excess resin. Curing at 70°C for 3 hours, peeling off the substrate surface after complete curing, polishing the surface to expose the carbon tube ends, and cutting the film with an ultramicr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com