S-shaped-track-based multi-cavity electron accelerator

An electron accelerator and trajectory technology, applied in the direction of electrical components, accelerators, etc., can solve the problems of large radio frequency power loss of single-cavity accelerators and difficulty in increasing the beam current power of electron beams, so as to avoid cavity heating and deformation and reduce processing difficulty , the effect of small envelope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

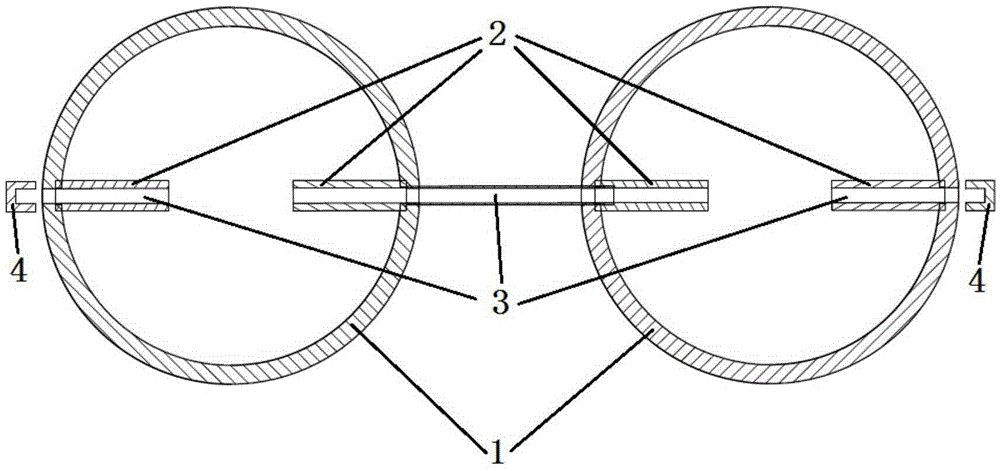

[0025] figure 1 , figure 2 What is shown is a serpentine trajectory accelerator using two resonant accelerating cavities, and the fundamental resonant frequencies of the cavities are both 100MHz. The diameter of the resonant accelerating cavity is about 1 meter, the length of the cavity is about 2 meters, the length of the electrode plate 2 is about 1.5 meters, and the axial distance between the two cavities is 1.5 meters. The electron beam is deflected 8 times on the same horizontal plane, and each linear movement is accelerated twice. The electron energy gain of each acceleration is 0.553MeV, and the distance between adjacent electron moving straight lines is 120mm.

[0026] The energy gain of the first and last acceleration of electrons in a cavity is the smallest, while the energy gain of the fifth acceleration is the highest, and the ridge electrode plate head 13 (such as Figure 5 The cancellation of shown) will lead to the deterioration of the inhomogeneity of the ac...

Embodiment 2

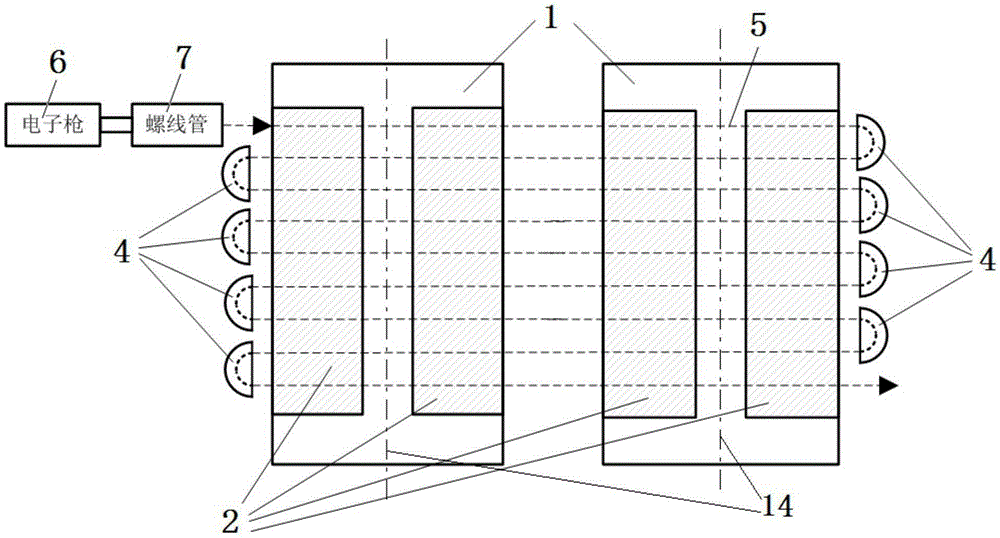

[0029] Image 6 , Figure 7What is shown is a serpentine trajectory accelerator using four resonant accelerating cavities, and the fundamental resonant frequencies of the cavities are all 200MHz. The cross-section of the resonant acceleration cavity is not a circle, but a square. The side length is about 0.5 meters, the cavity length is about 2 meters, the trapezoidal electrode plate 2 is about 1.5 meters long, and the axial distance between the two cavities is 0.75. Meter. The electron beam is deflected 8 times on the same horizontal plane, and each linear motion is accelerated 4 times. The electron energy gain of each acceleration is 0.276MeV, and the distance between adjacent electron motion straight lines is 120mm. The RF loss of a single cavity is 50kW, and the output electron beam energy is 10MeV.

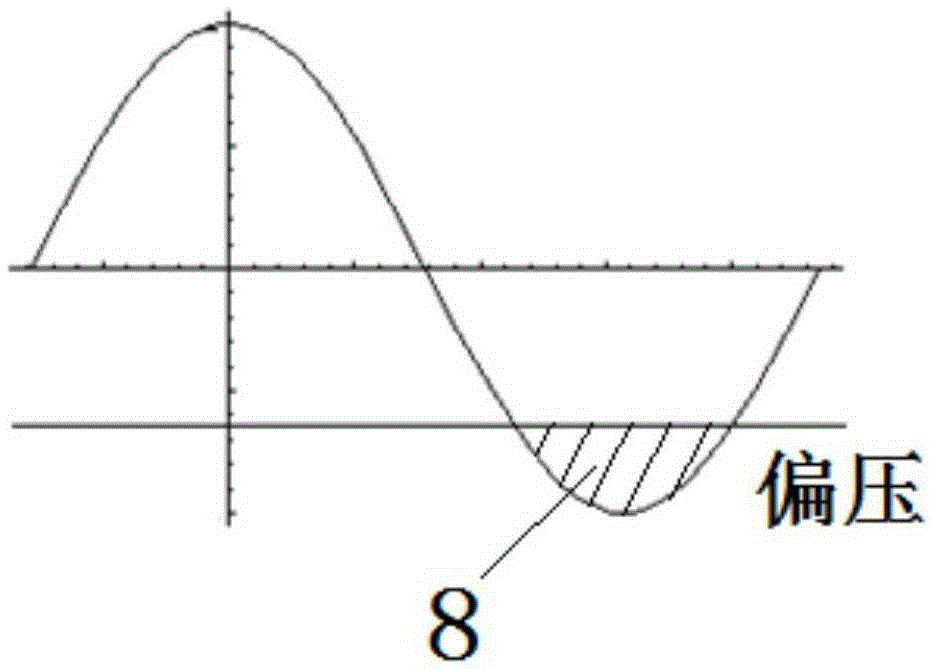

[0030] The gate-controlled electron gun structure adopts Figure 4 As shown, the gate control voltage waveform adopts image 3 shown. The voltage of the cathode of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com