Luminous unit coplanar structure of micro light emitting diode display

A technology of micro light-emitting diodes and light-emitting units, which is applied to the light-emitting unit structure of green and green displays, can solve the problems of high production cost of horizontal chips, unfavorable display cost control, and influence on the uniformity of light-emitting units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

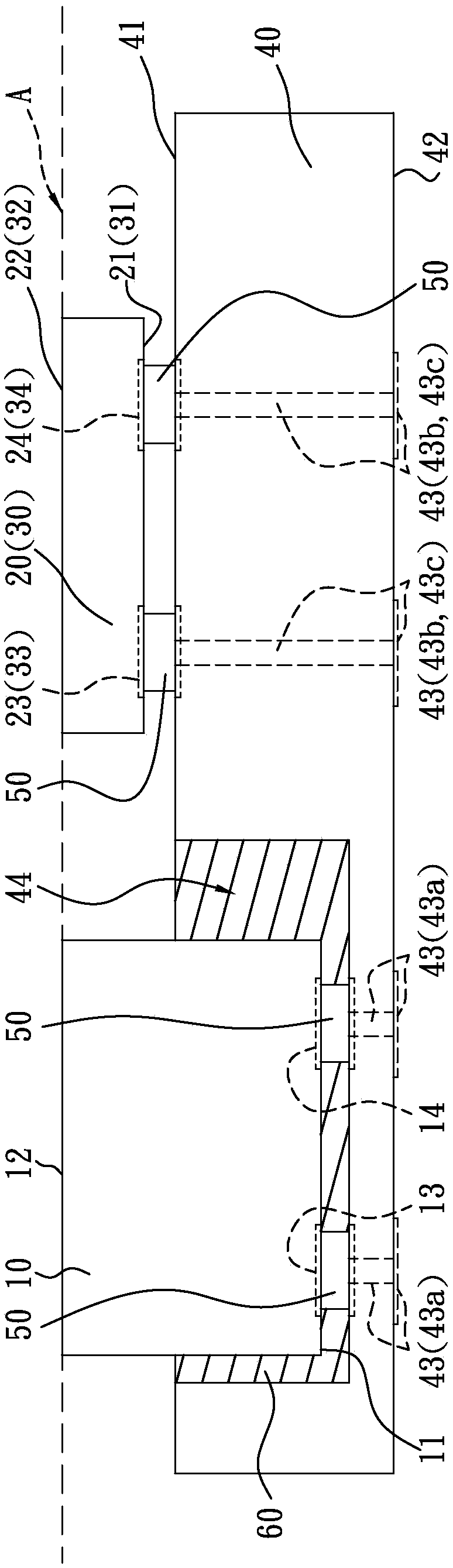

[0023] In order to make the present invention more definite and detailed, the preferred embodiments are listed hereby together with the following diagrams, and the structure and technical characteristics of the present invention are described in detail as follows, wherein each diagram is only used to illustrate the structural relationship and related functions of the present invention , so the size or shape or size of each part is not set according to the actual scale and is not used to limit the present invention:

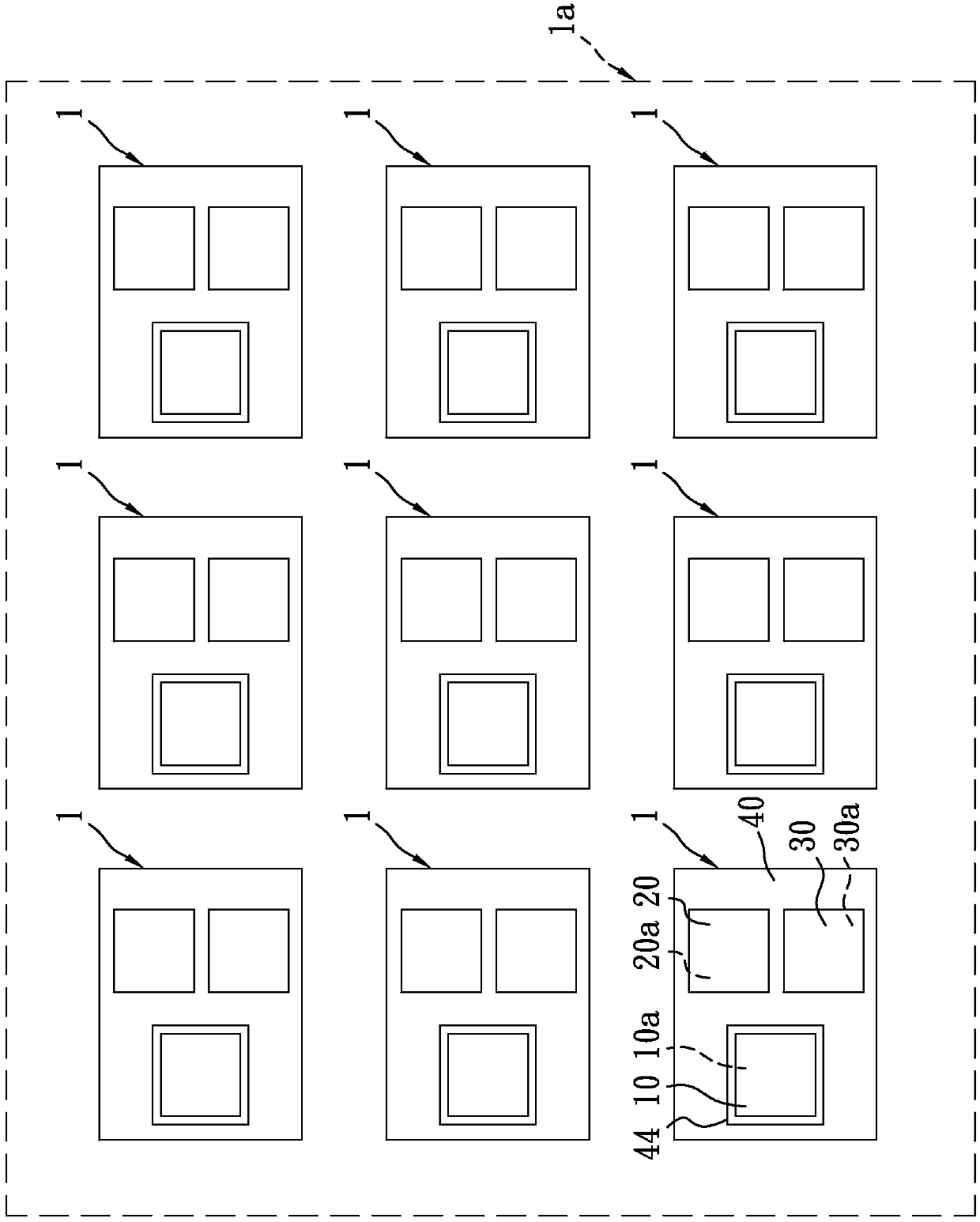

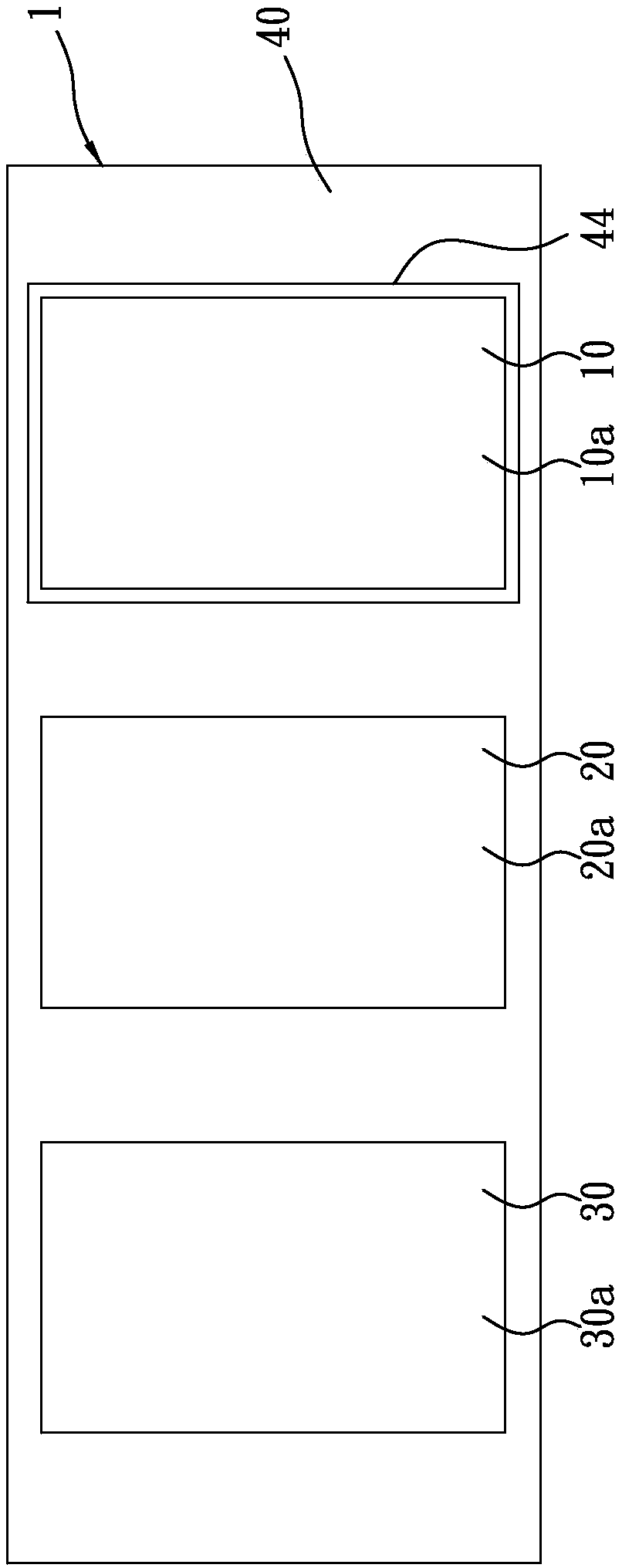

[0024] refer to figure 1 , the micro-light-emitting diode (LED) display of the present embodiment is made up of a plurality of light-emitting units 1 arranged on a substrate (chip) 1a and forming an array, wherein each light-emitting unit 1 (please refer to figure 1 shown in the lower left corner of ) is composed of a red LED chip 10, a green LED chip 20 and a blue LED chip 30 arranged and electrically connected on a carrier board 40, but not limited, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com