Micro light-emitting diode display and manufacturing method thereof

A technology of micro-light-emitting diodes and displays, which is applied in the direction of instruments, electric solid-state devices, semiconductor devices, etc., and can solve problems such as complicated manufacturing steps, poor contact between micro-light-emitting diode chips and display backplanes, and unsuitability for rapid production of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

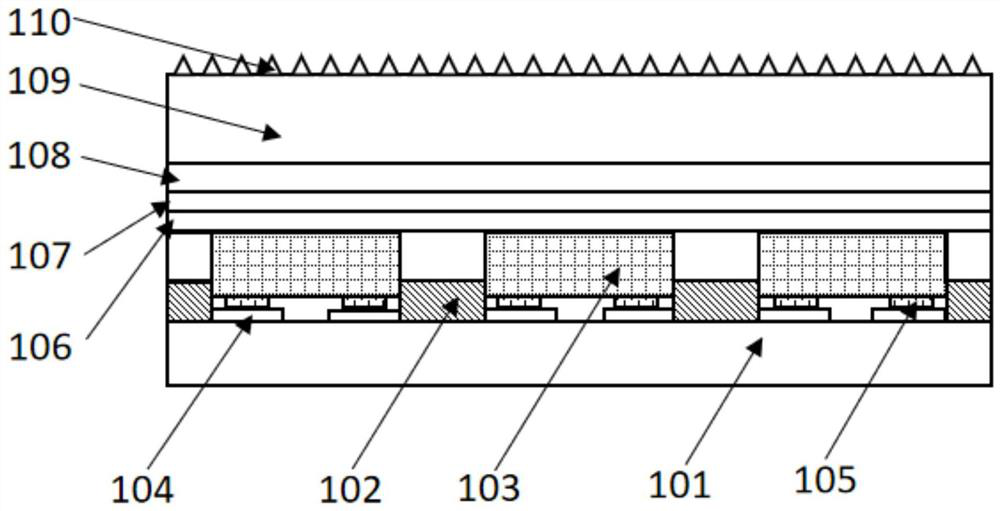

[0048] A micro light-emitting diode display of the present invention is described in detail below with an embodiment of a flip-chip display, please refer to figure 1 , which includes:

[0049]Display backplane 101, said display backplane 101 is a thin film transistor (TFT, Thin Film Transistor) backplane, said display backplane 101 is provided with three or more mutually separated limiting components, wherein the limiting component is preferably A light-shielding photoresist 102 with a light-shielding function, the light-shielding photoresist 102 includes: a white photoresist or a black photoresist; every two adjacent limiting components form an installation position for limiting the diode chip, The mounting position is matched with the side wall of the diode chip 103, and the light-shielding photoresist 102 can be connected with both sides of the metal pad assembly 104, and can also be left with a certain amount of space on both sides of the metal pad assembly 104. gap, and ...

Embodiment 2

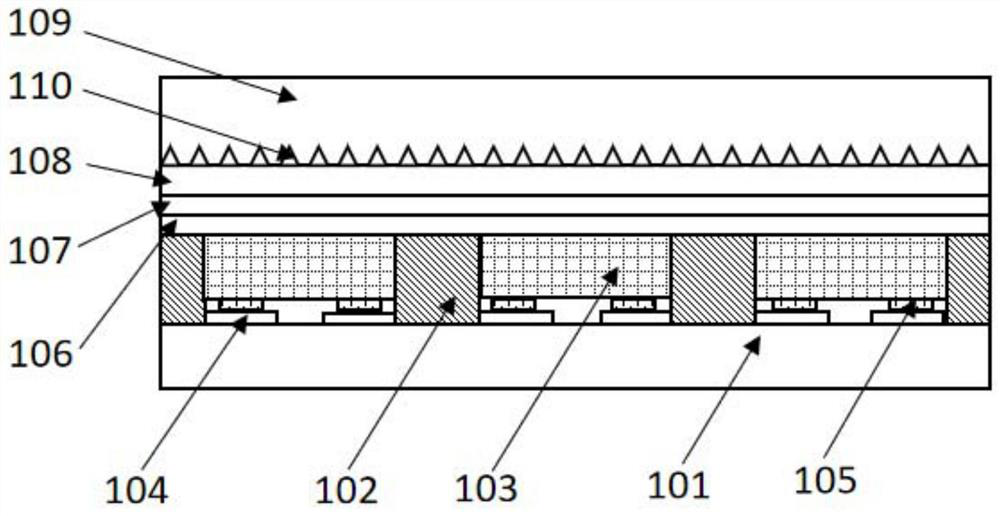

[0051] A micro light-emitting diode display of the present invention is described in detail below with another embodiment of a flip-chip display, please refer to figure 2 , which includes:

[0052] Display backplane 101, said display backplane 101 is a thin film transistor backplane, said display backplane 101 is provided with more than three mutually separated limiting components, wherein the limiting component is preferably a light-shielding photoresist with a light-shielding function 102, the light-shielding photoresist 102 includes: a white photoresist or a black photoresist; every two adjacent limiting components form an installation position for limiting the diode chip 103, and the installation position is consistent with the Cooperate with the side wall of the above-mentioned diode chip 103, the light-shielding photoresist 102 can be connected with both sides of the metal pad assembly 104, and can also leave a certain appropriate gap with the two sides of the metal pad...

Embodiment 3

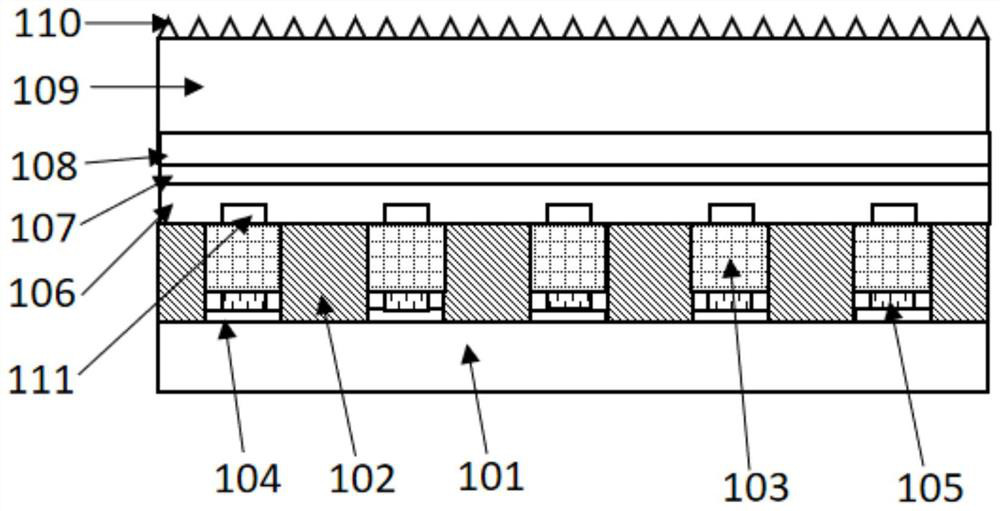

[0054] A kind of micro light-emitting diode display of the present invention is specifically described below with the embodiment of a vertical structure chip display, please refer to image 3 , which includes:

[0055] Display backplane 101, said display backplane 101 is a thin film transistor backplane, said display backplane 101 is provided with more than three mutually separated limiting components, wherein the limiting component is preferably a light-shielding photoresist with a light-shielding function 102, the light-shielding photoresist 102 includes: a white photoresist or a black photoresist; every two adjacent limiting components form an installation position for limiting the diode chip 103, and the installation position is consistent with the Cooperate with the side wall of the above-mentioned diode chip 103, the light-shielding photoresist 102 can be connected with both sides of the metal pad assembly 104, and can also leave a certain appropriate gap with the two si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com