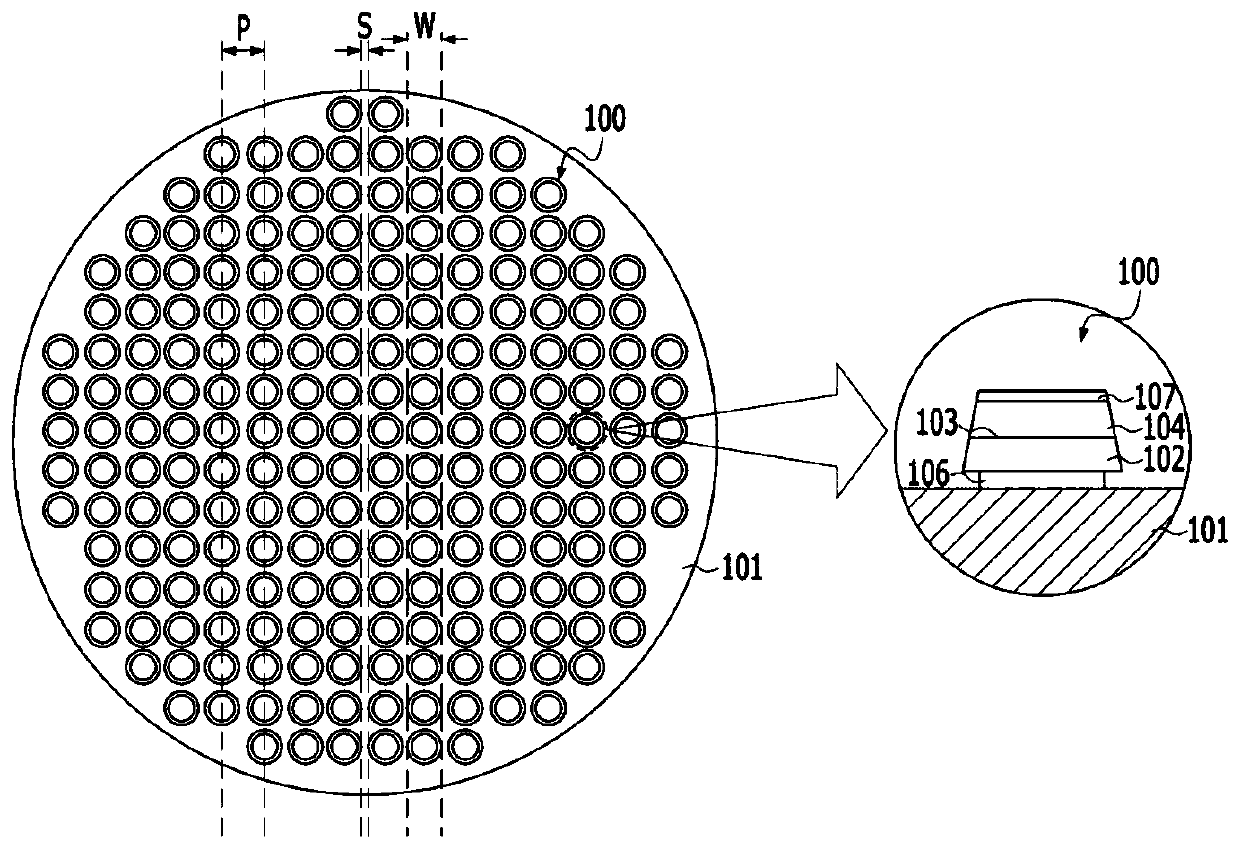

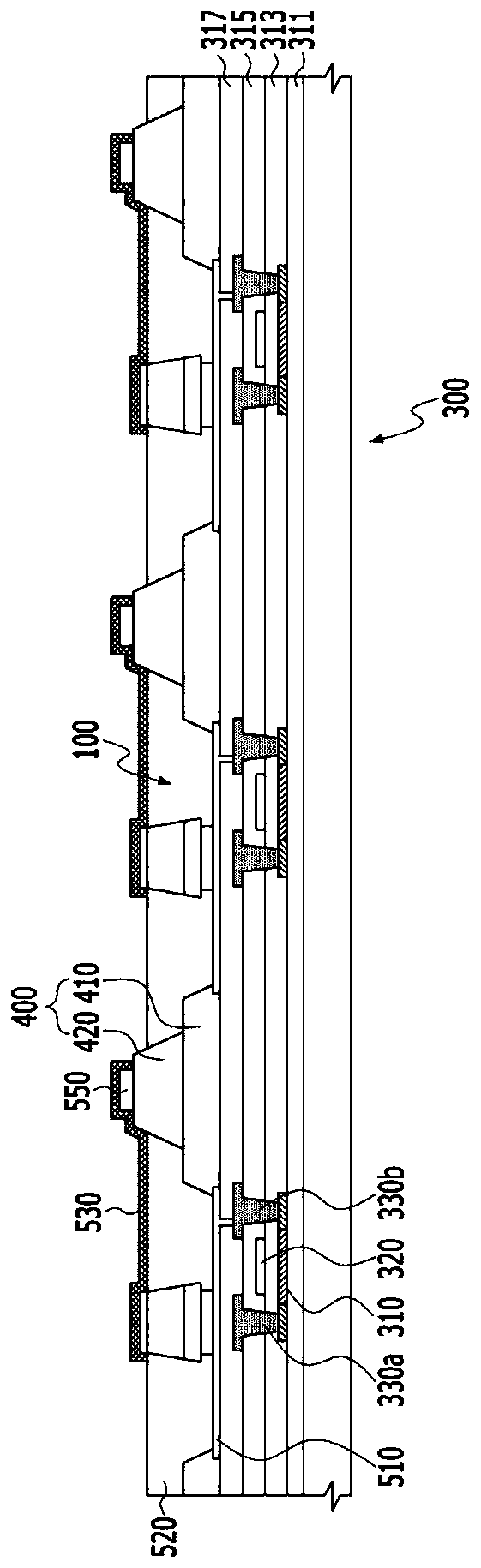

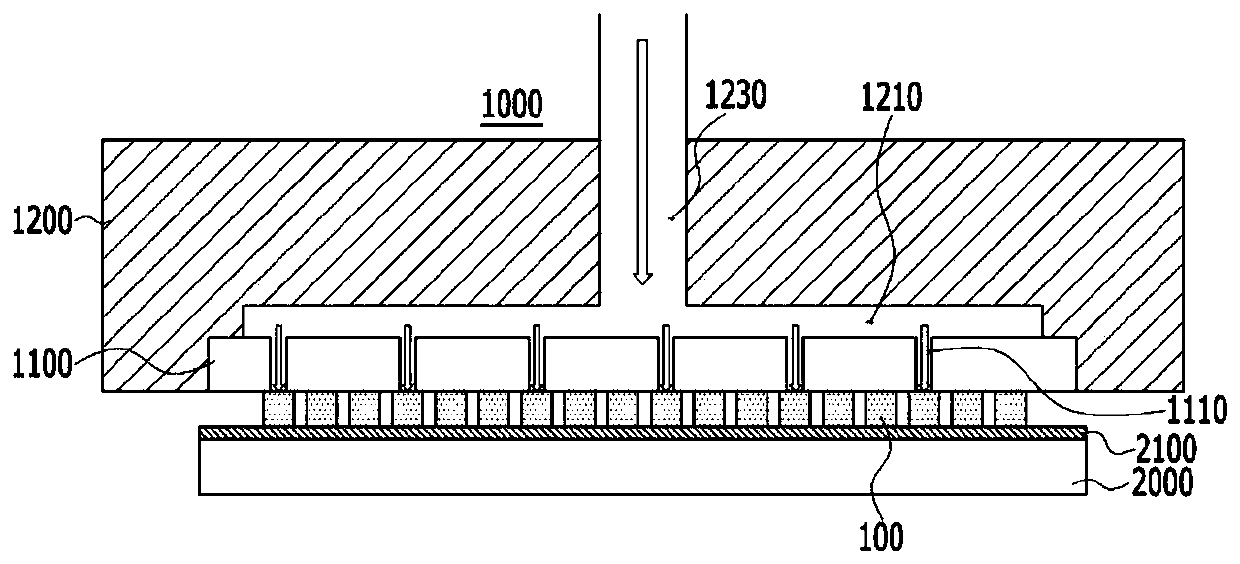

Hot air supplying head for transferring micro LED and micro LED transferring system

A technology of micro light-emitting diodes and transfer heads, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve the problems of scattered alignment, continuous use of adhesives, damage, etc., and achieve an effective transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following merely illustrates the principles of the invention. Therefore, although not explicitly described or illustrated in this specification, those skilled in the art can realize the principle of the invention and invent various devices included in the concept and scope of the invention. In addition, it should be understood that all conditional terms and examples listed in this specification are only for clearly understanding the concept of the invention in principle, and are not limited to such specifically listed examples and states.

[0055] The above-mentioned purpose, features, and advantages will become more apparent from the following detailed description related to the accompanying drawings, so those skilled in the art to which the invention pertains can easily implement the technical idea of the invention.

[0056] Embodiments described in this specification will be described with reference to cross-sectional views and / or perspective views which are id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com