Intelligent SMT production error-proof tracing method and process

An error-proofing and process technology, applied in electrical components, printed circuit manufacturing, electrical components, etc., can solve problems such as difficulty in ensuring functional integrity and traceability, poor product reliability, etc., to ensure traceability and increase production and delivery. Qualification rate, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

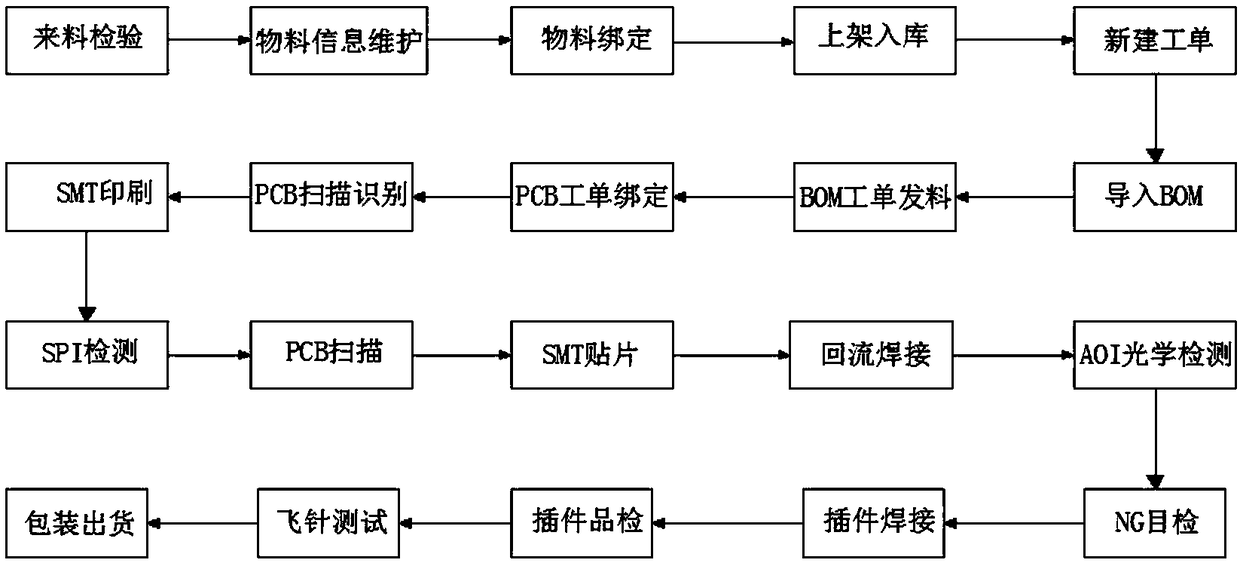

[0031] refer to figure 1 , an SMT production intelligent error-proof traceability method and process, comprising the following steps:

[0032] S1. Incoming material inspection: First, take stock of the quantity of materials, conduct a preliminary inspection of the appearance of the materials, and check whether there are damages or scratches;

[0033] S2. Material information maintenance: check the material information, obtain the material specification model, production date, production batch, brand, etc., enter the work order number in the system to bring up the material loading record form;

[0034] S3. Material binding: Bind the material tray information, bind th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com