Fully automatic horizontal flying needle test system

A flying probe test, fully automatic technology, applied in the field of horizontal flying probe test system, can solve the problems of limitation, low test efficiency, and inability to meet the test work of large quantities of circuit boards, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

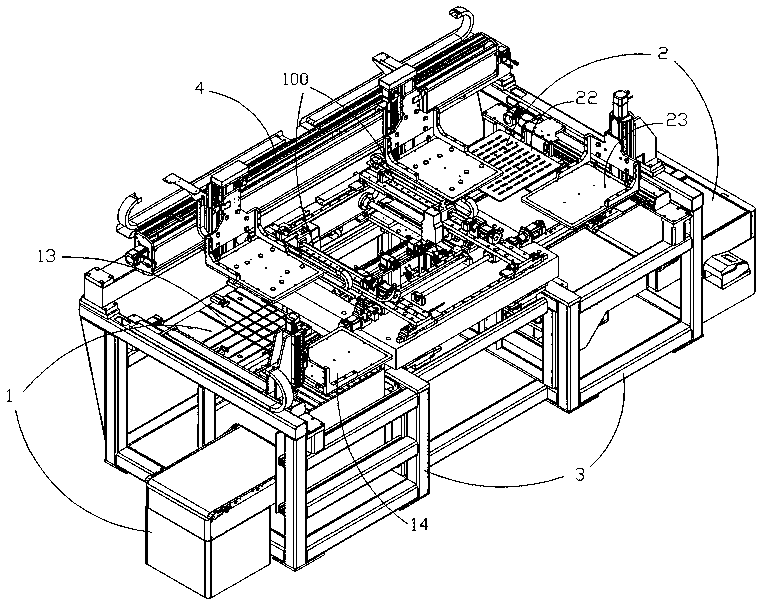

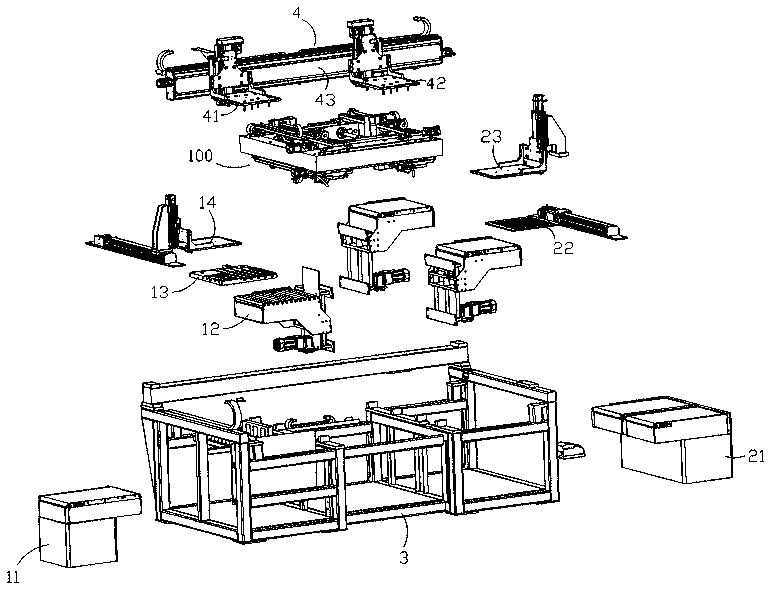

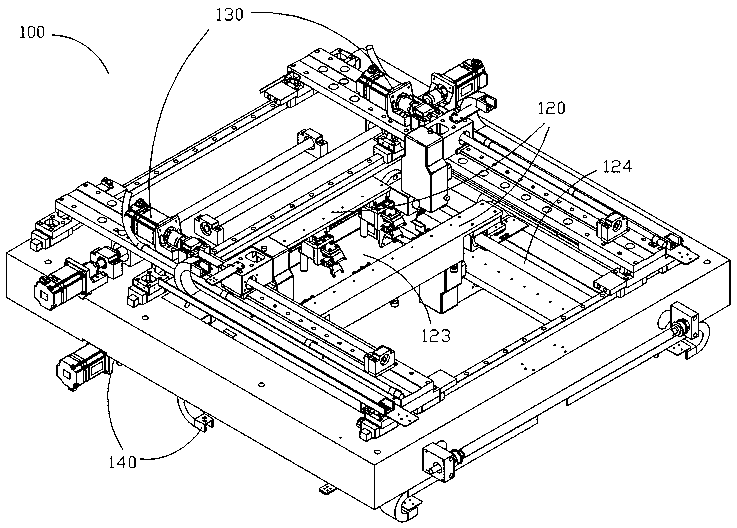

[0023] Such as Figures 1 to 10 As shown, a fully automatic horizontal flying probe testing system includes a feeding part 1 , a horizontal flying probe testing host 100 and a discharging part 2 .

[0024] Such as Figures 1 to 2 As shown, the feeding part 1 , the horizontal flying probe test host 100 and the discharging part 2 are set on the frame 3 at the same time.

[0025] Wherein, the feeding part 1 and the discharging part 2 are respectively arranged at two ends of the horizontal flying probe testing host 100 .

[0026] An automatic feeding part 4 is also provided on one side of the horizontal flying probe test host 100 .

[0027] The circuit board to be detected is first placed on the feeding part 1, and then the automatic feeding part 4 grabs the circuit board into the horizontal flying probe test host 100 for fixing and completes the detection, and then the The automatic feeding part 4 grabs the tested circuit boards to the discharging part 2, and completes the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com