Flying probe tester utilizing planar motor

A flying probe testing machine and plane motor technology, applied in the field of flying probe testing machines, can solve problems such as unreasonable structure and inability to meet test accuracy, and achieve the effects of simple structure, high test speed, and reasonable and reliable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

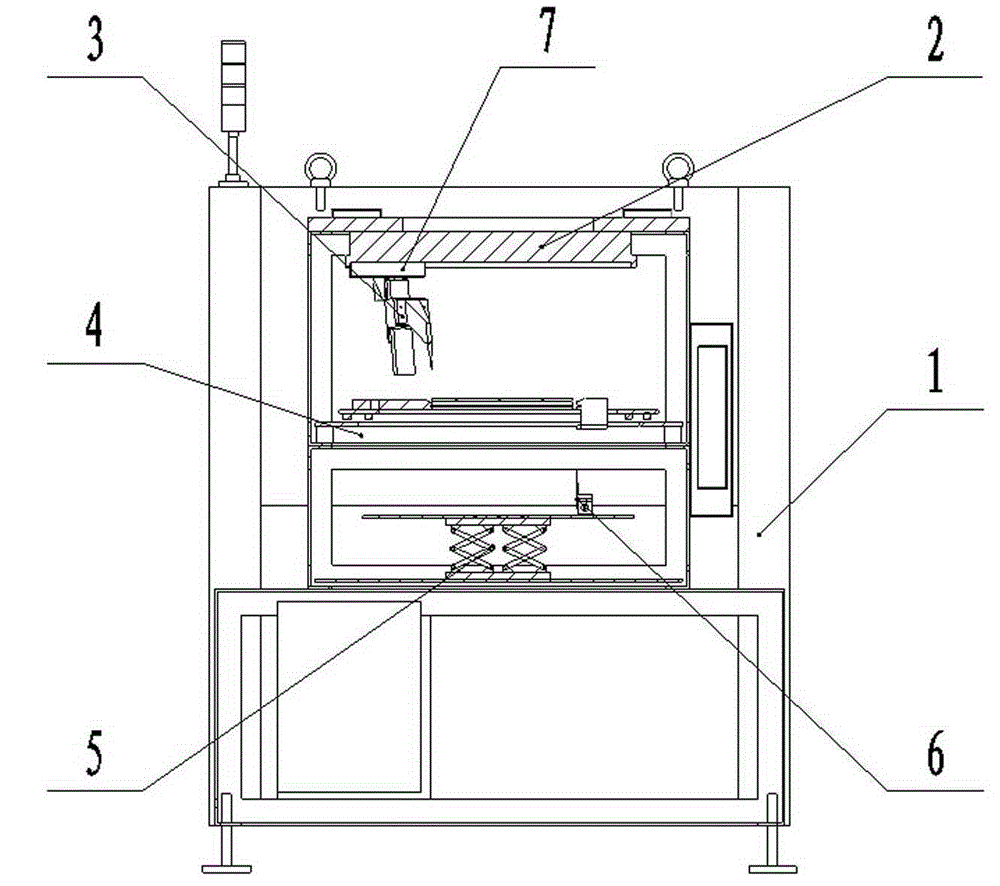

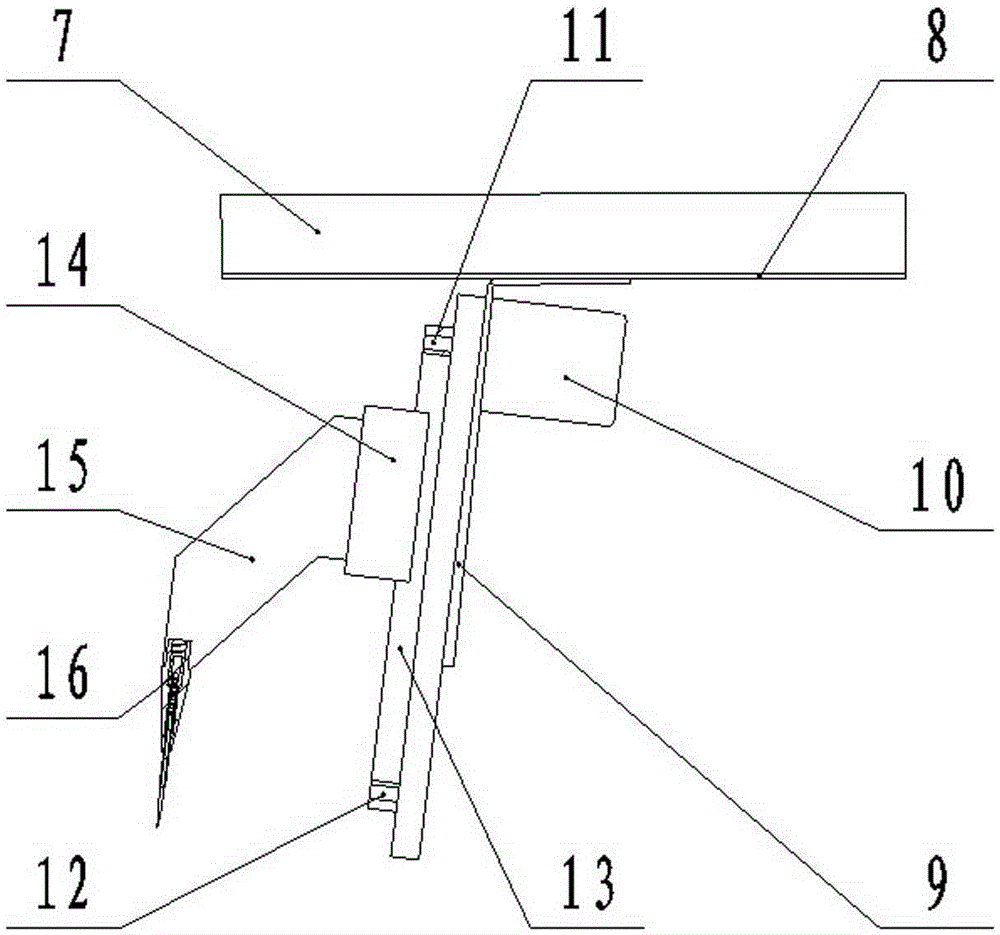

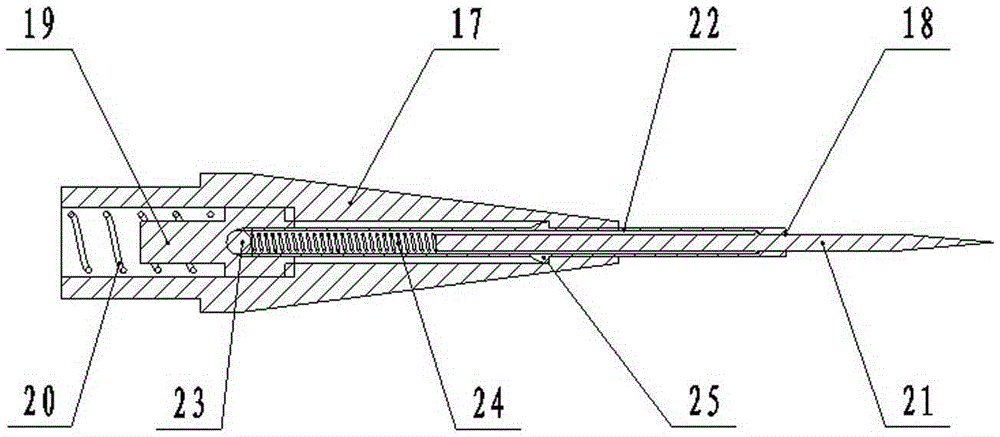

[0016] A flying probe testing machine using a planar motor includes a frame 1, which is provided with a planar motor stator 2 distributed up and down, a probe loading device 3, a circuit board positioning fixture 4 and a lifting platform 5, and the lifting platform 5 is provided with The fixed probe 6 in contact with the lower surface of the circuit board, the probe loading device 3 includes a mover body 7 sliding on the surface of the plane motor stator 2, the mover body 7 surface is provided with a mover base plate 8, and the mover base plate 8 is fixed with a The support 9 that is arranged obliquely, a side of support 9 is fixed with linear motor 10, and the other side of support 9 is provided with driving wheel 11 and driven wheel 12, and driving wheel 11 is connected with the output shaft of linear motor 10, and driving wheel 11 is connected with A transmission belt 13 is provided between the driven wheels 12, a slide block 14 is provided on the transmission belt 13, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com