Planar flying probe tester and PCB transmission method

A flying probe testing machine and PCB board technology, applied in the field of testing machines, can solve the problems of low re-testing efficiency and occupying much time, so as to improve the re-testing efficiency, high test stability and accuracy, reduce the scrap rate and re-testing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

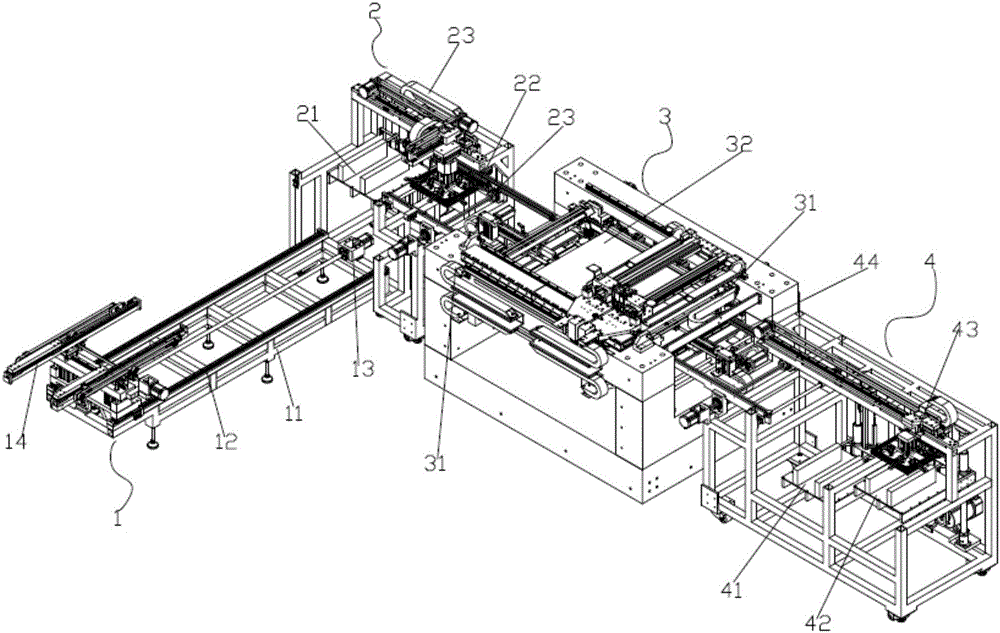

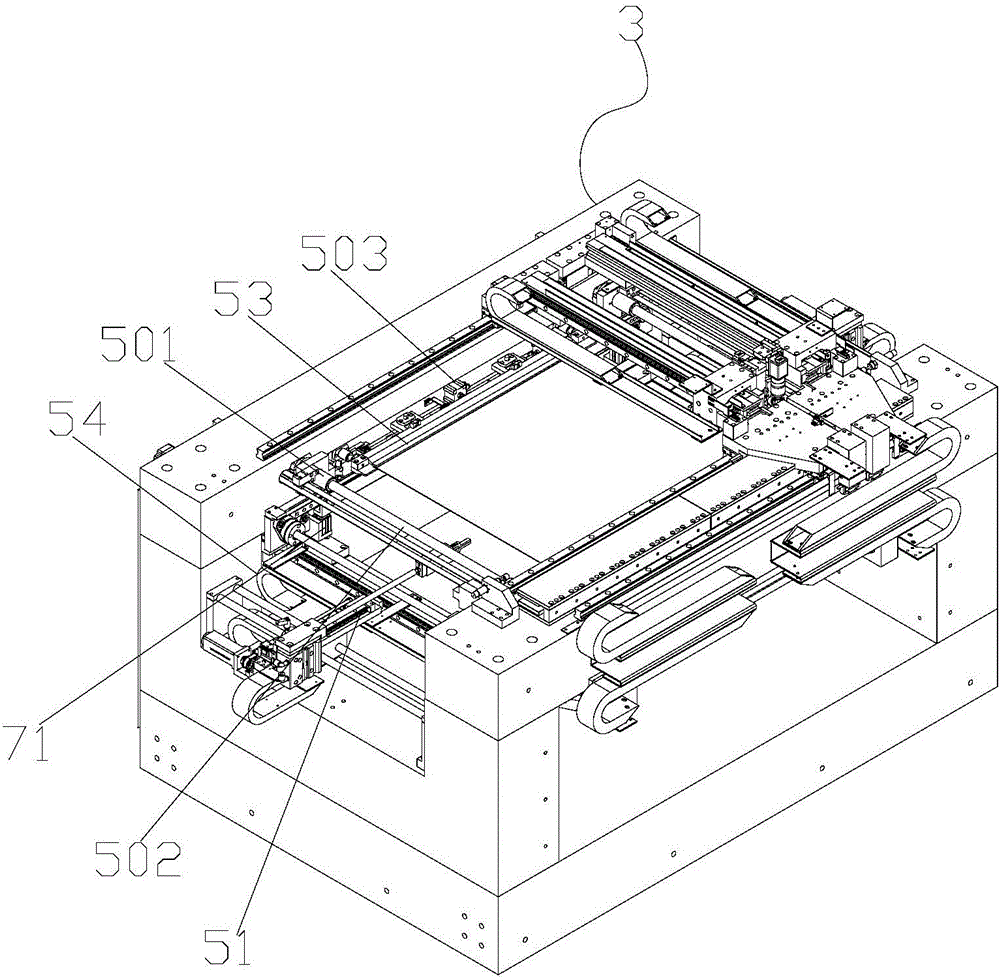

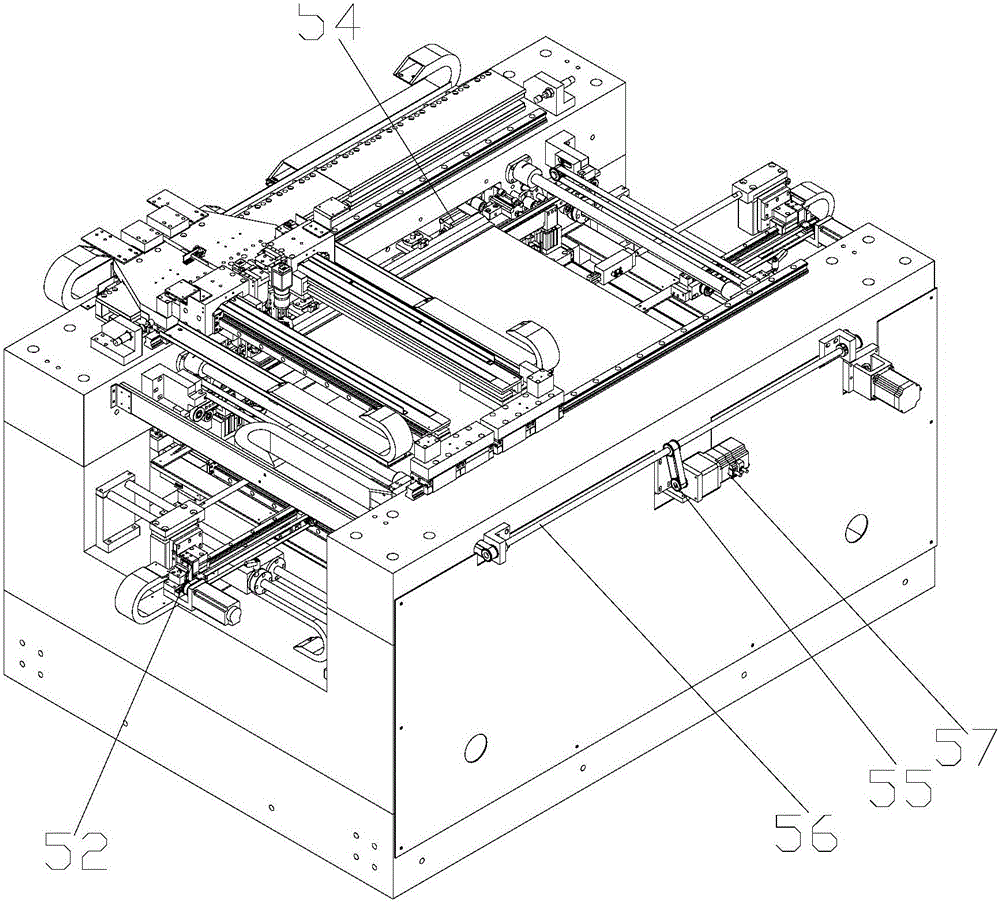

[0029] like figure 1 As shown, the embodiment of the present invention provides a planar flying probe testing machine, including a material receiving mechanism 1 , a material loading mechanism 2 , a flying probe test host 3 and a material unloading mechanism 4 .

[0030] Described material receiving mechanism 1 comprises base 11, and this base 11 is provided with sliding guide rail 12, material fetching driving device 13, and the material fetching mechanism 14 that takes out the unqualified PCB board to be tested of needle bed test table in order, The pick-up device 14 is arranged on the sliding guide rail 12, and the pick-up device 14 is driven to move by the pick-up driving device 13. When the pick-up device 1 receives the pick-up instruction, the pick-up mechanism 14 stretches into the needle bed, and will be placed on the needle bed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com