Flying probe test machine fast alignment method

A flying probe testing machine, fast technology, applied in printed circuit testing, electronic circuit testing, etc., can solve the problems of low production efficiency, long time consumption, and long time consumption, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and specific embodiments.

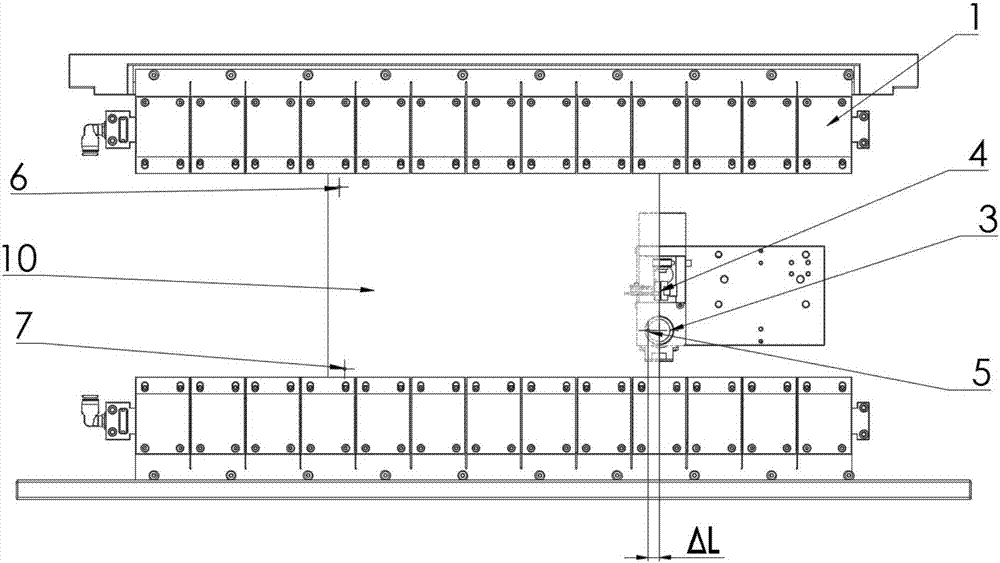

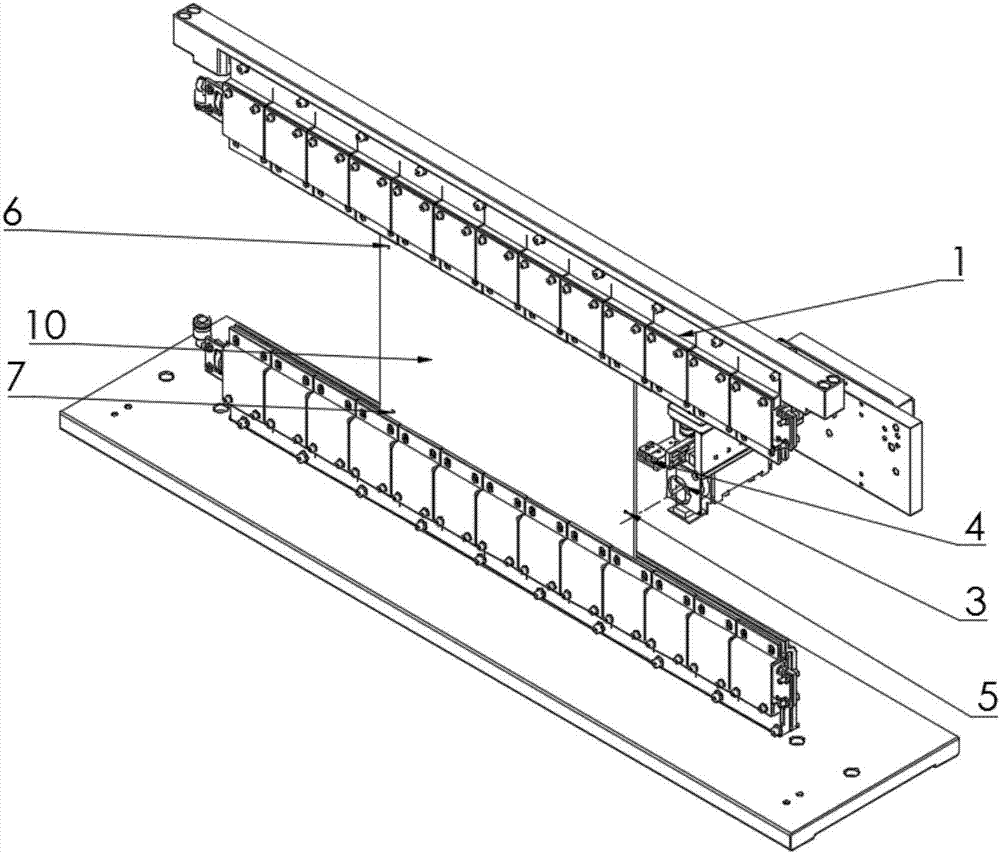

[0021] See figure 1 , The present invention provides a fast alignment method for a flying probe tester, the flying probe tester includes one or more test shafts, wherein at least one test shaft is provided with a test probe and a CCD camera, and the alignment The method includes the following steps:

[0022] The first step: Take any PCB board 10 to be tested with a regular shape and install it in the fixture 1 of the flying probe tester;

[0023] Step 2: Retrieve the test data corresponding to the PCB board 10, the test data includes the distance ΔL from the edge of the PCB board 10 to the first alignment point 5 in the X-axis direction, and the test data also includes The angle and distance between the alignment points, the angle and distance between the CCD camera 3 and the test probe 4, and the distance when the test axis of the same plane is at the origin;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com