Electrical performance testing method for multi-material number spliced board

A technology of electrical performance testing and testing method, applied in the field of electrical performance testing of multi-material number composite panels, can solve the problems of test effect influence, low operation efficiency, high labor cost, reduce testing operations, improve work efficiency, reduce The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in detail below:

[0023] The method for testing the electrical properties of multi-material number combination boards of the present invention comprises the following steps:

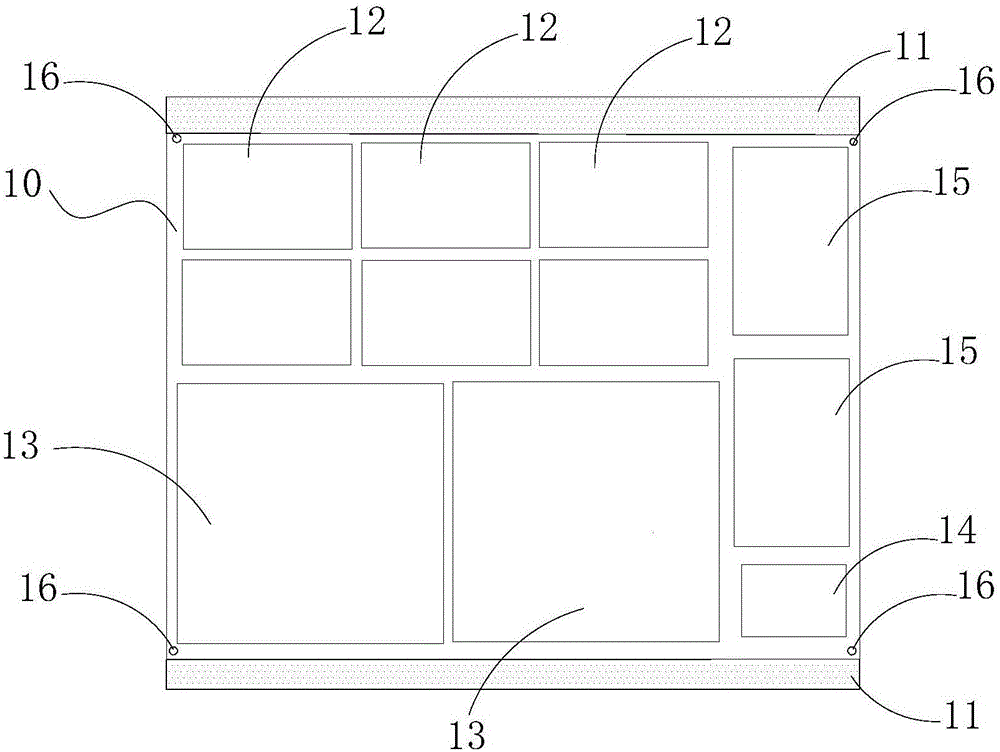

[0024] Step 1: Assemble multiple single-number boards onto one production board 10 . figure 1 As shown in the figure, 6 first single material number plates 12, 2 second single material number plates 13, 1 third single material number plate 14 and 2 fourth single material number plates 15 are combined in the same production board. Wherein, the single item number board has multiple network units. The plate material and thickness, number of laminations, copper thickness, ink type, surface technology and manufacturing process of each of the single-number plates are the same. The network unit includes branches formed by series and / or parallel connection of electronic components such as resistors, capacitors, and inductors, that is, each electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com