Manufacturing method of Micro LED flexible circuit board

A technology of flexible circuit boards and manufacturing methods, which is applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., which can solve the problems of inability to guarantee quality, product deformation and shrinkage, and matrix pad line deviation To solve problems such as large tolerances, to ensure the accuracy of exposed offset, improve bonding force, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will now be further described with reference to the drawings and specific embodiments.

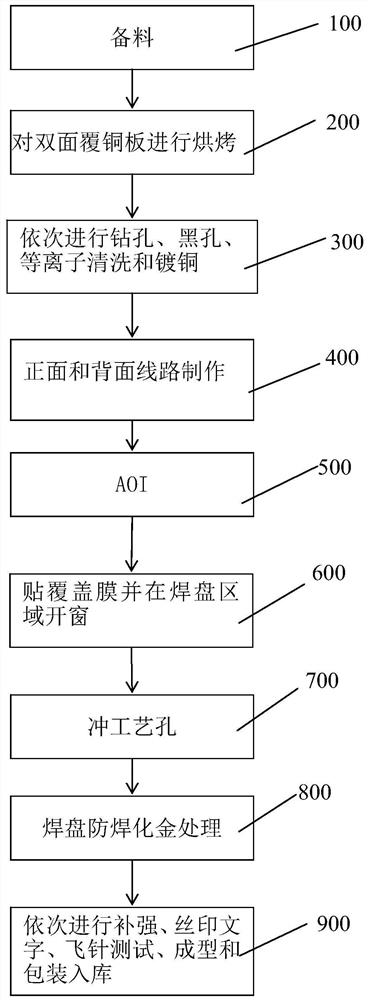

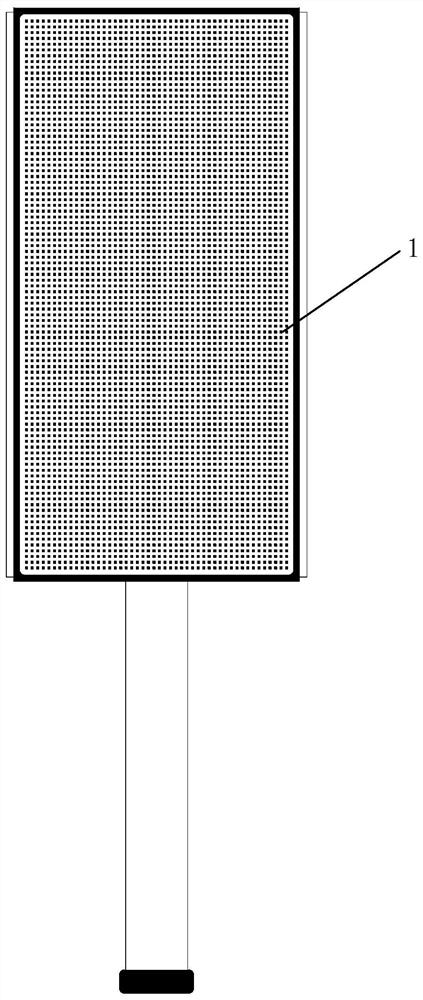

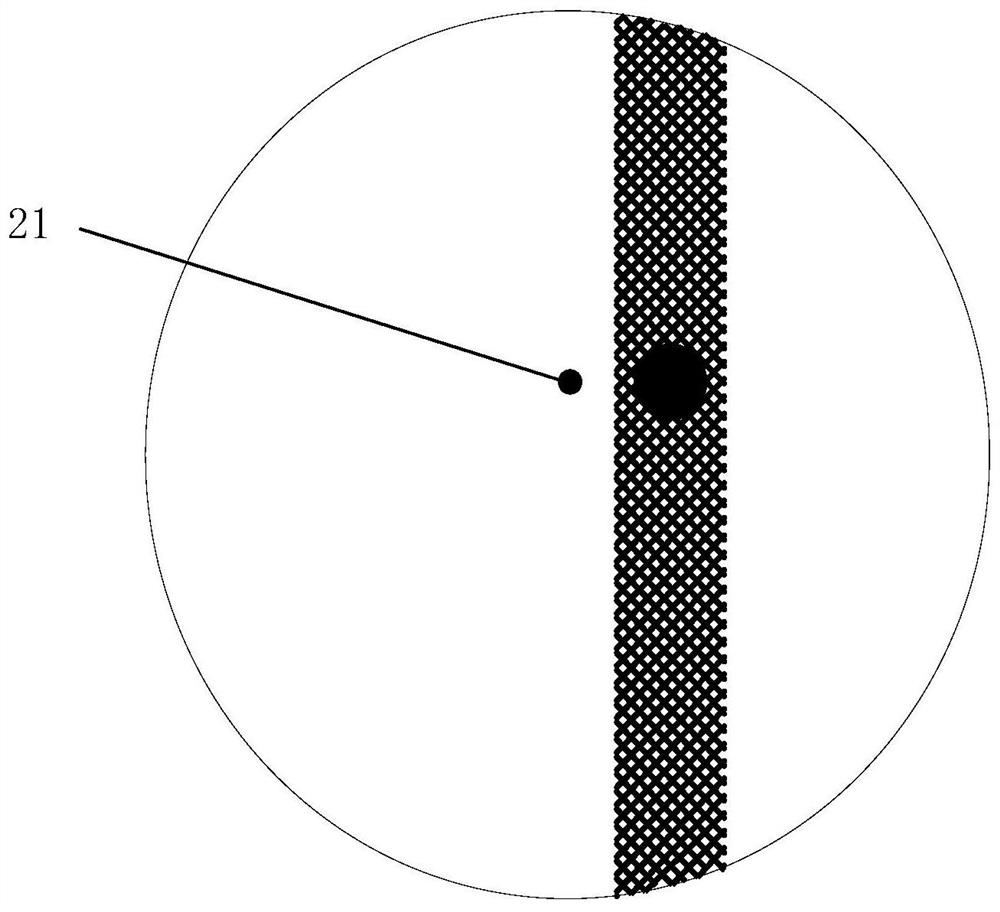

[0023] Reference figure 1 with 2 , Describes a method for manufacturing a Micro LED flexible circuit board, wherein the Micro LED flexible circuit board is a double-sided board, the main body width d1 is less than 2 mm, and the frame width d2 is less than 0.1 mm. The method includes the following steps:

[0024] 100. Material preparation. The double-sided copper clad laminate is cut into a predetermined size, which is suitable for manufacturing a plurality of Micro LED flexible circuit board products arranged in an array. The double-sided copper clad laminate is a 1 / 3OZ halogen-free adhesive double-sided substrate. Specifically, the double-sided copper clad laminate includes a substrate layer, a white glue layer and a copper layer stacked from the inside to the outside. The thickness of the substrate layer is 13 microns, the thickness of the white glue layer is 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com