A method for manufacturing a micro LED flexible circuit board

A flexible circuit board and manufacturing method technology, which is applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, and printed circuits, etc. Guarantee quality and other issues to achieve the effect of improving product quality, improving bonding force, and ensuring the accuracy of exposed offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

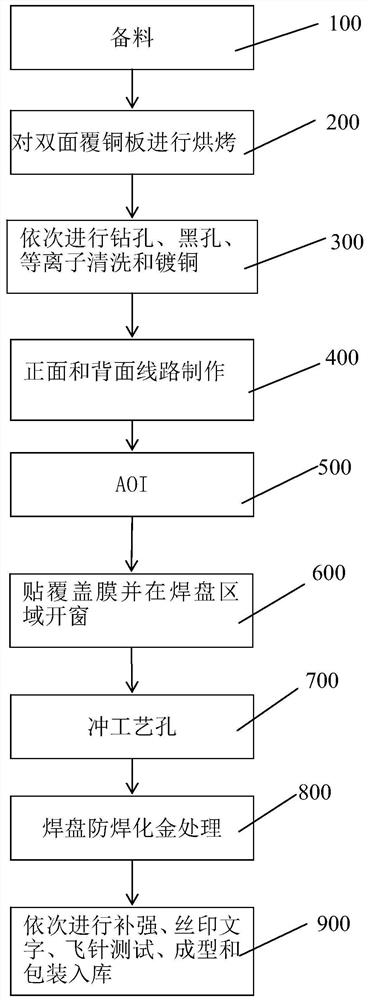

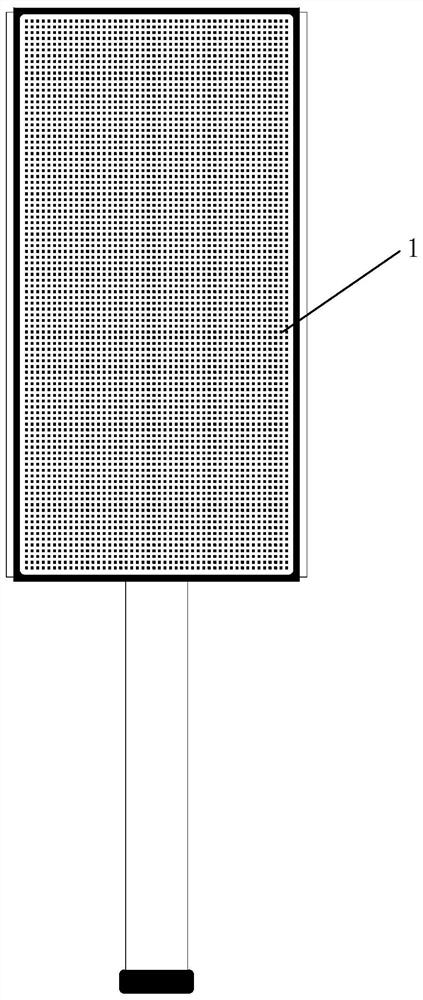

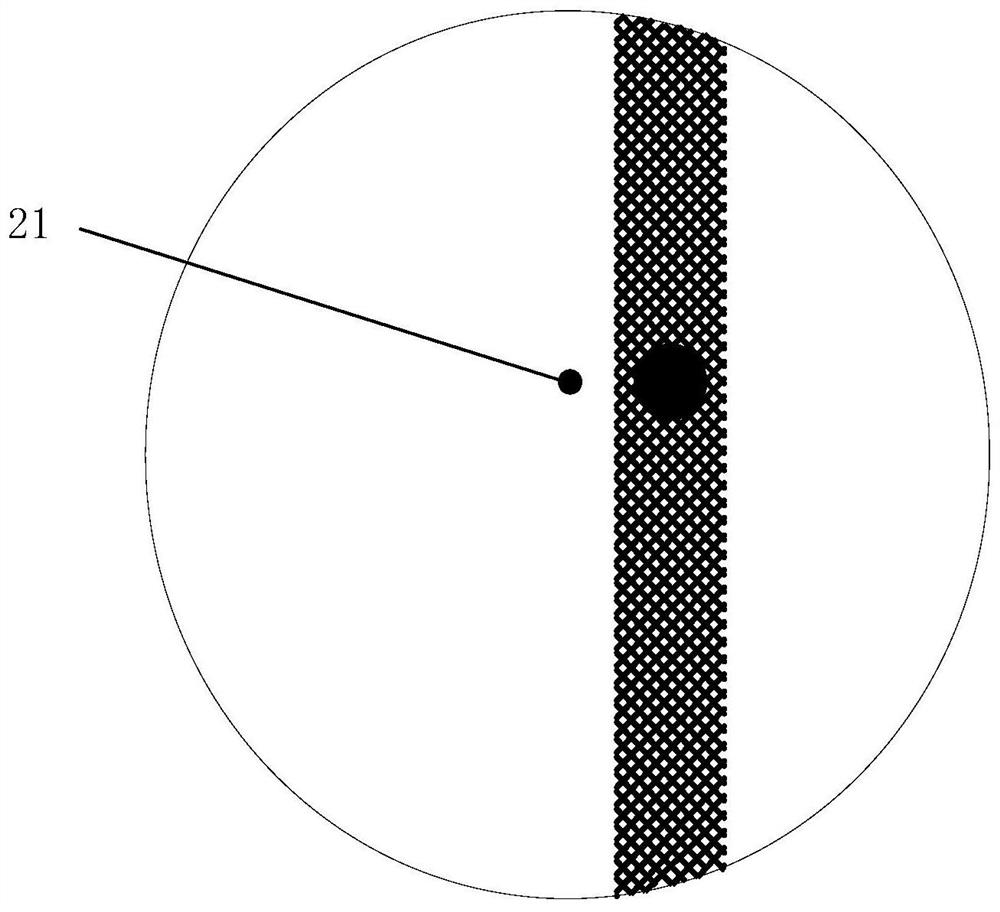

[0023] refer to figure 1 and 2 , describes a method for manufacturing a Micro LED flexible circuit board, wherein the Micro LED flexible circuit board is a double-sided board, its main body width d1 is less than 2 mm, and the frame width d2 is less than 0.1 mm, the method includes the following steps:

[0024] 100. Prepare materials. Cut the double-sided copper-clad laminate into a predetermined size, which is suitable for making multiple Micro LED flexible circuit board products arranged in an array. The double-sided copper-clad laminate is a 1 / 3OZ halogen-free adhesive double-sided substrate. Specifically, the double-sided copper-clad laminate includes a substrate layer, a white glue layer and a copper layer stacked from the inside to the outside. Wherein, the thickness of the substrate layer is 13 microns, the thickness of the white glue layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com