Method of testing unloaded, large-area printed circuit boards with a finger tester

A technology for circuit boards and testers, which is applied in printed circuit testing, electronic circuit testing, non-contact circuit testing, etc., and can solve problems such as the development, production and operation of super-large probe testers, which are expensive and the number of testers is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

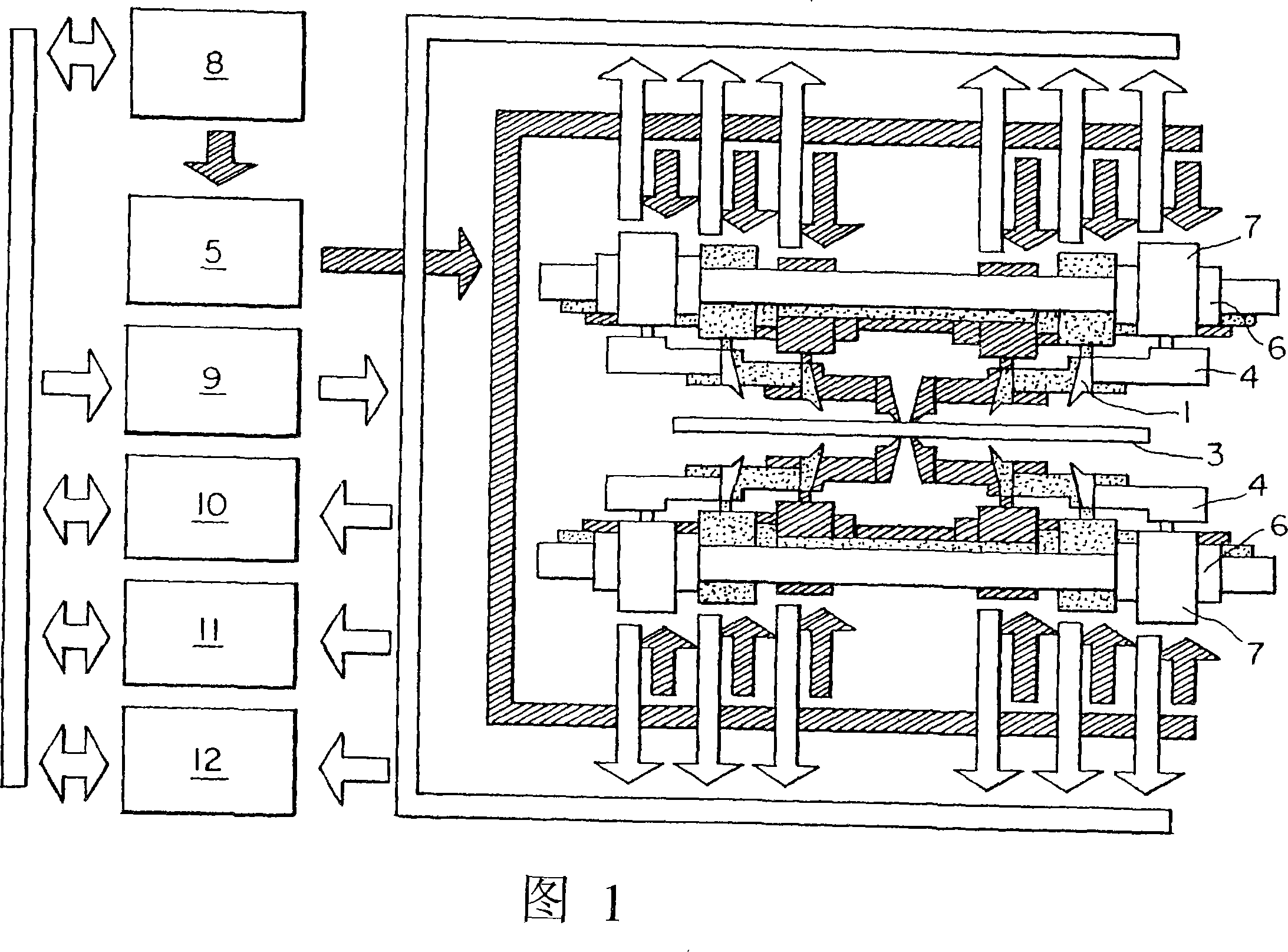

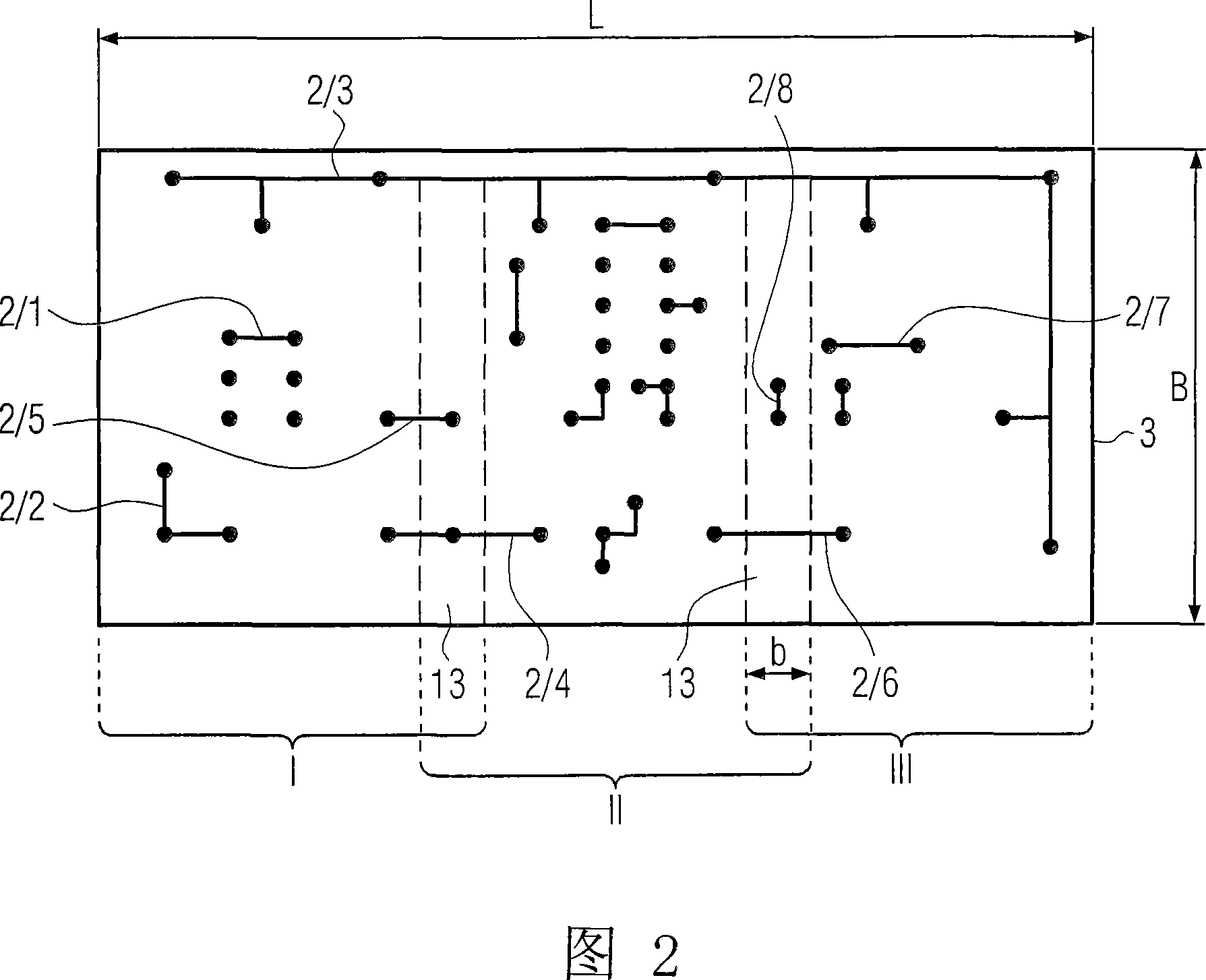

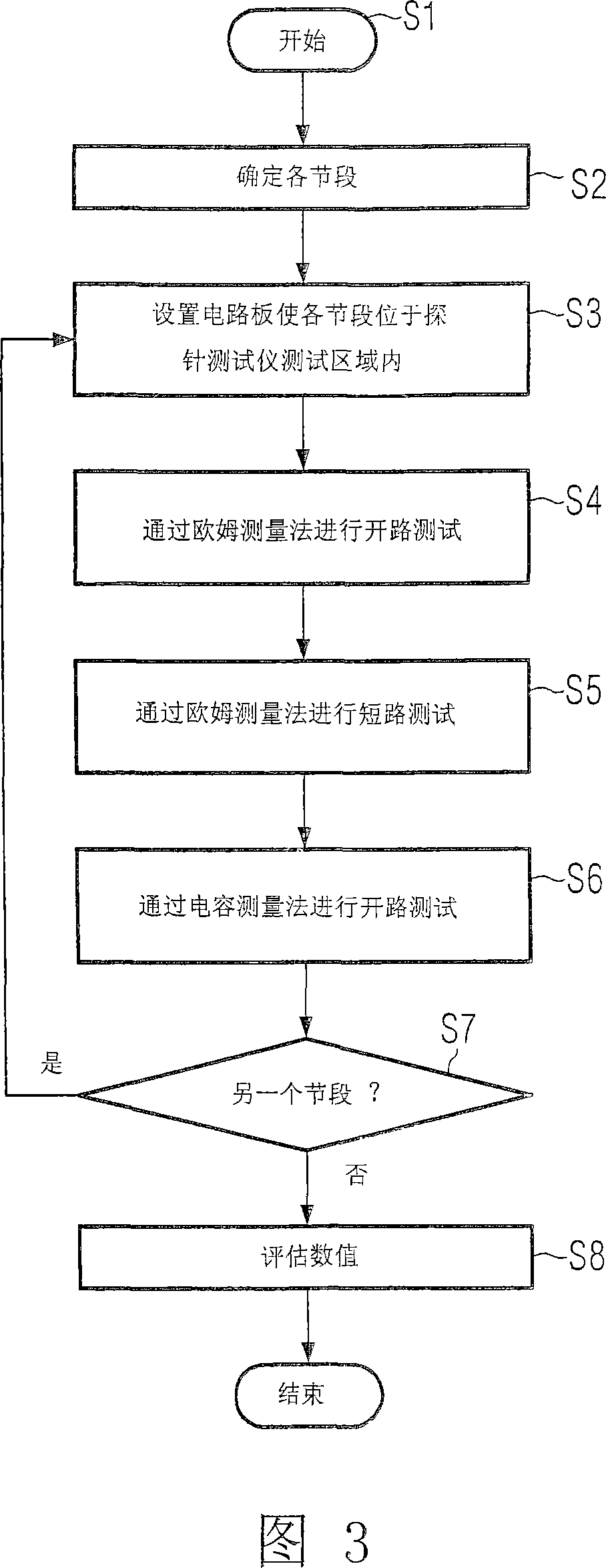

[0027] The method according to the invention for testing large, non-componentized circuit boards with conductor paths is carried out by means of a probe tester. The probe tester has several test electrodes 1 which can be brought into contact with the circuit board test points of the conductor paths 2 of the circuit board 3 (FIGS. 1, 2). Each test electrode 1 is integrated in a contact probe 4 . In this example, the probe tester contains a composite probe system, the composite probe system contains 12 contact probes 4 in total, and every 6 contact probes are placed on one side of the circuit board 3 to be tested on the side. EP0468135A1 discloses a pointer probe in which contact probes are independently movable relative to further contact probes. The contact probes 4 are movable parallel to the surface of the circuit board 3 so that the test electrodes 1 can be brought into contact with specific circuit board test points of the conductor paths. Each of said contact probes 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com