Resistivity monitoring method used in P type epitaxial wafer production

An epitaxial wafer and resistivity technology, applied in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of long epitaxial growth process time, increase production cost, reduce product production efficiency, etc., to reduce repeated resistivity test, avoid test errors, and reduce the effect of test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

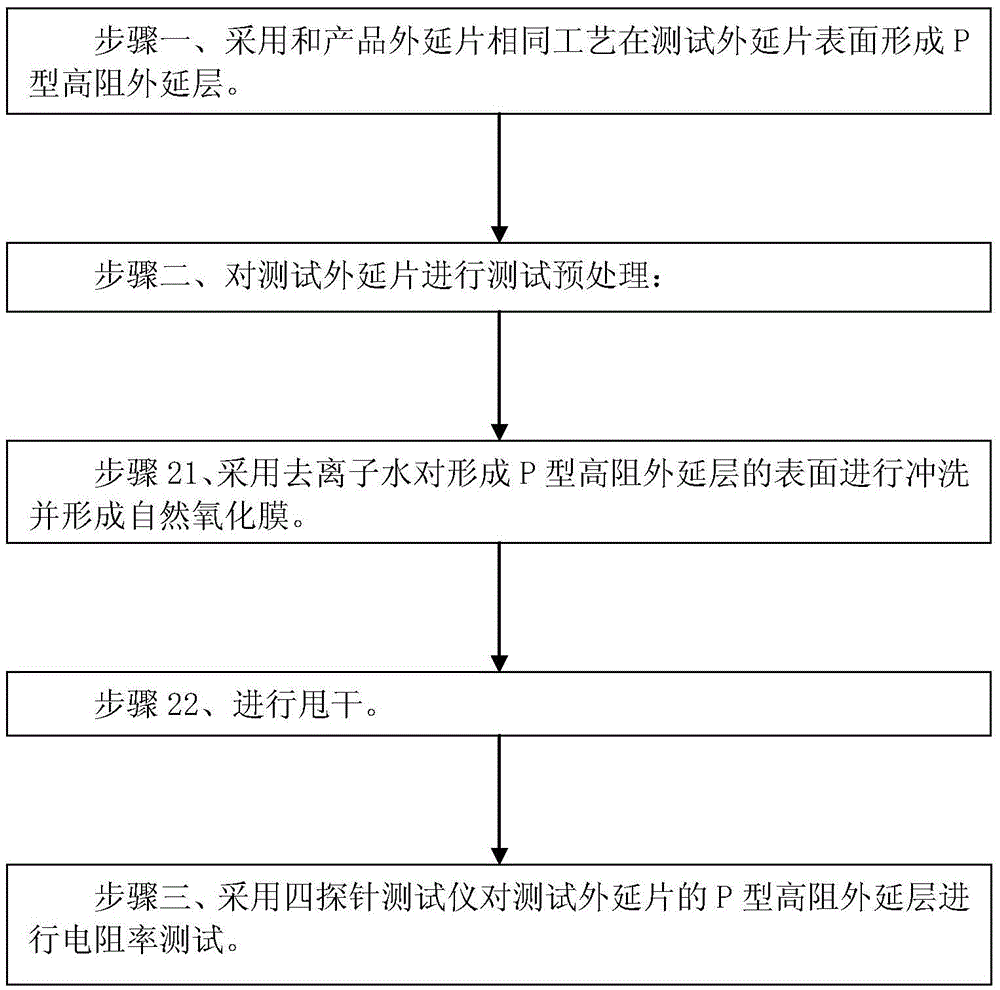

[0023] Such as figure 1 Shown is the flow chart of the method of the embodiment of the present invention, the resistivity monitoring method in the production of the P-type epitaxial wafer of the embodiment of the present invention comprises the following steps:

[0024] Step 1. Using the same production process as the P-type epitaxial layer of the product epitaxial wafer to form a P-type epitaxial layer on the surface of the test epitaxial wafer, and monitor the P-type epitaxial layer of the product epitaxial wafer through the P-type epitaxial layer of the test epitaxial wafer. layer resistivity. In the embodiment of the present invention, the P-type epitaxial layer of the product epitaxial wafer is a P-type high-resistance epitaxial layer with a resistivity greater than 10 ohm·cm. When the P-type epitaxial resistivity is greater than 10 ohm·cm, the epitaxial process will use a large H2 is used as a carrier gas, so that there will be a large number of -H, -CH bonds on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com