Method for improving vanadium dioxide phase change amplitude by regulating sputtering power

A technology of sputtering power and vanadium dioxide, which is applied in the field of increasing the phase transition amplitude of vanadium dioxide by regulating sputtering power, can solve the problems of high process requirements of the phase transition amplitude, etc., and achieves short preparation time, easy control, and process conditions. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Sapphire cleaning

[0026] The sapphire used is double-polished sapphire with (001) crystal face purchased in the market, and the size is 1cm*1cm. Put the sapphire sheet into deionized water, acetone and absolute ethanol in sequence for ultrasonic cleaning, each cleaning time is 20 minutes, to remove the inorganic and organic impurities on the surface; then wash it with deionized water, and finally clean the sapphire substrate Put into absolute ethanol for later use. 2) Preparation of metal vanadium thin film

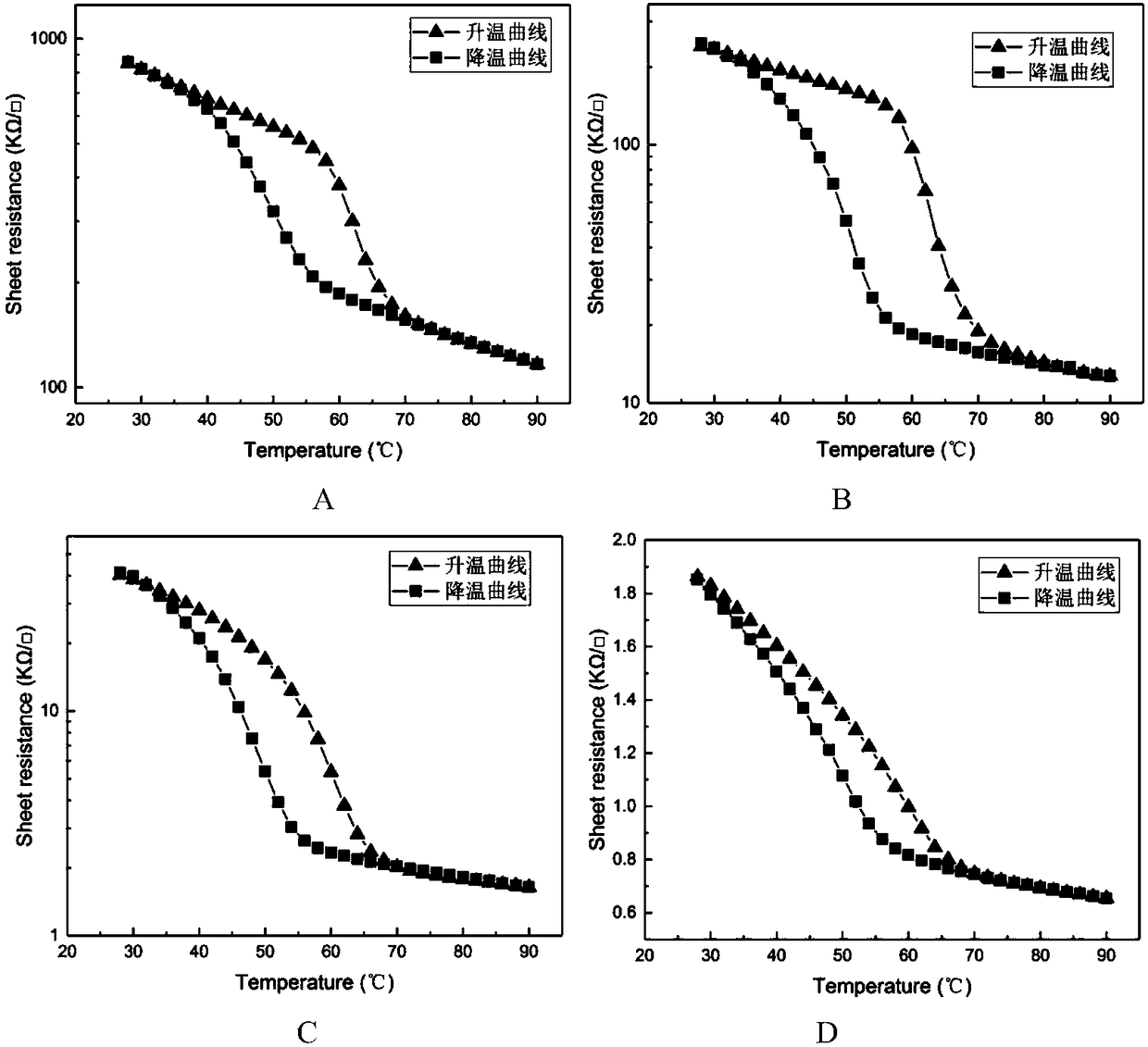

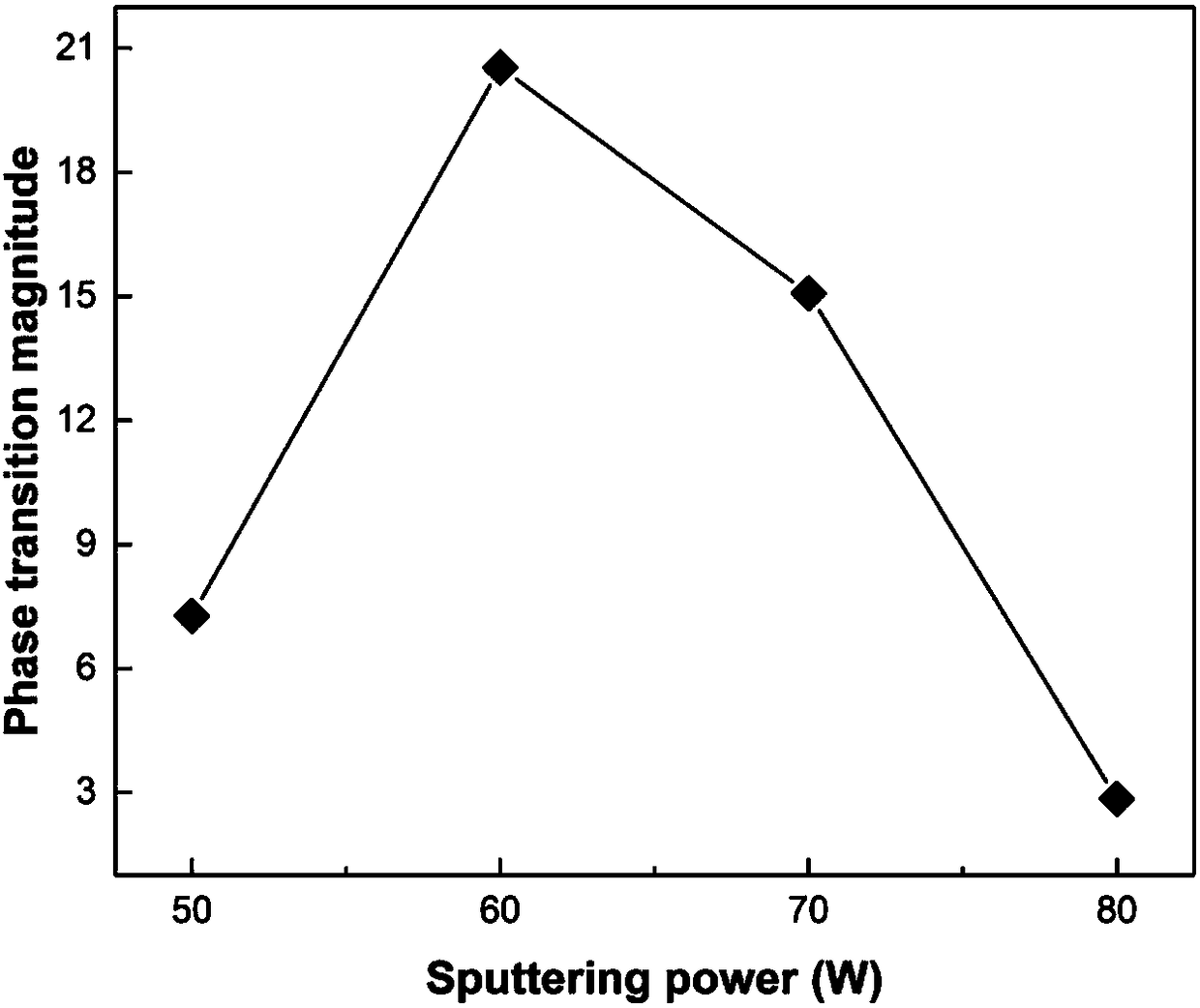

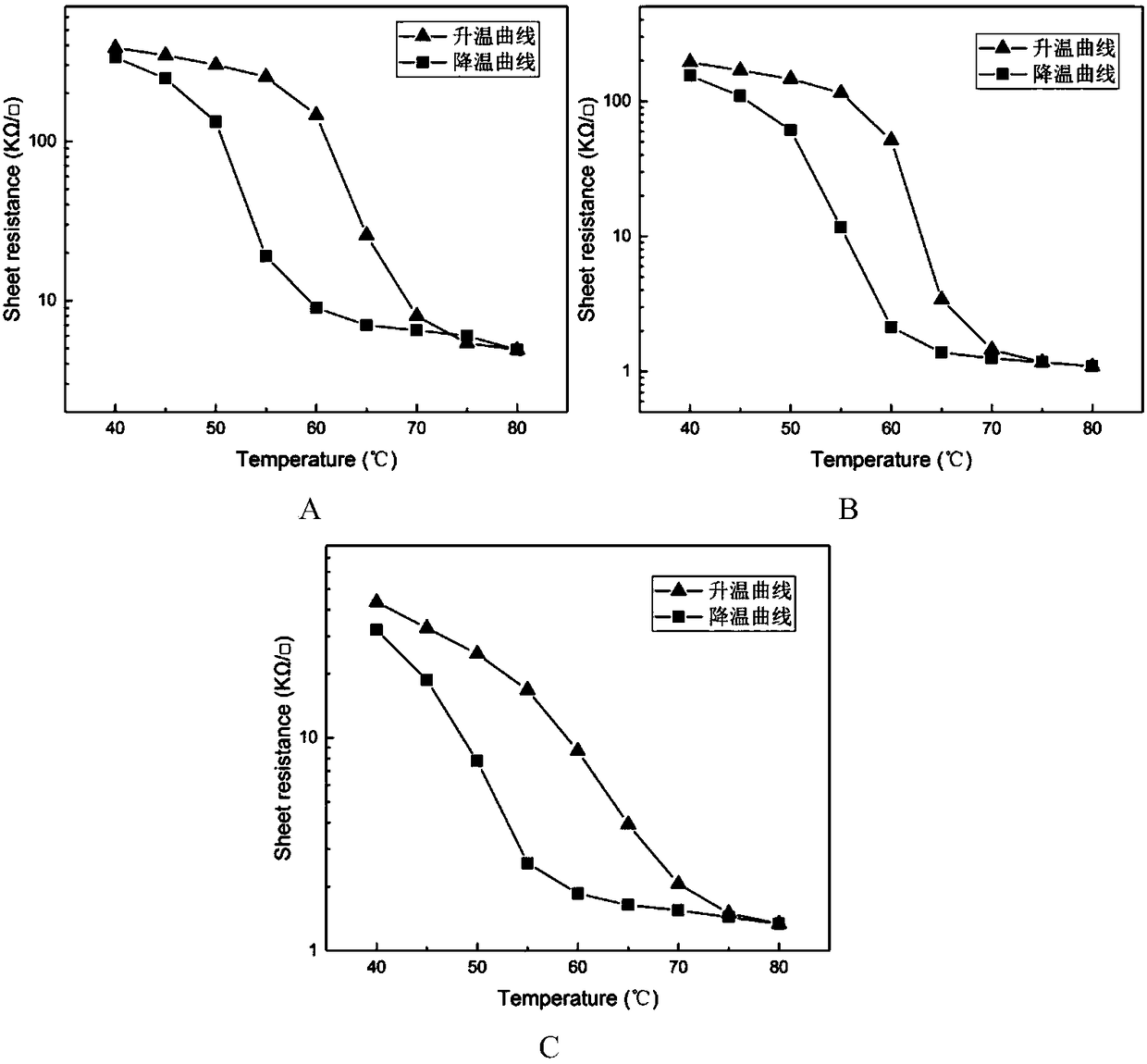

[0027] The cleaned sapphire substrate is placed in the vacuum chamber of the DPS-Ⅲ ultra-high vacuum target magnetron sputtering coating machine, and the metal vanadium with a mass purity of 99.99% is used as the target material, and the argon gas with a mass purity of 99.999% is used as the target material. Working gas, background vacuum 4.0×10 -4 Pa, the substrate is not heated during the sputtering process, the argon gas flow rate is 48mL / min, the sputte...

Embodiment 2

[0031] 1) Sapphire cleaning

[0032] The sapphire used is double-polished sapphire with (001) crystal face purchased in the market, and the size is 1cm*1cm. Put the sapphire sheet into deionized water, acetone and absolute ethanol in sequence for ultrasonic cleaning, each cleaning time is 20 minutes, to remove inorganic and organic impurities on the surface; then wash it with deionized water, and finally clean the sapphire substrate Put into absolute ethanol for later use. 2) Preparation of metal vanadium thin film

[0033] Place the cleaned sapphire substrate in the vacuum chamber of a DPS-Ⅲ ultra-high vacuum target magnetron sputtering coating machine, use metal vanadium with a mass purity of 99.99% as the target material, and use argon gas with a mass purity of 99.999% as the target material. Working gas, background vacuum 4.0×10 -4 Pa, the substrate is not heated during the sputtering process, the flow rate of argon gas is 48mL / min, the working pressure of sputtering is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com