Fluid control device

A technology for fluid control devices and fluid control valves, which is applied in the direction of fluid pressure actuators, lifting devices, servo motors, etc., and can solve the problem of unstable operability of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

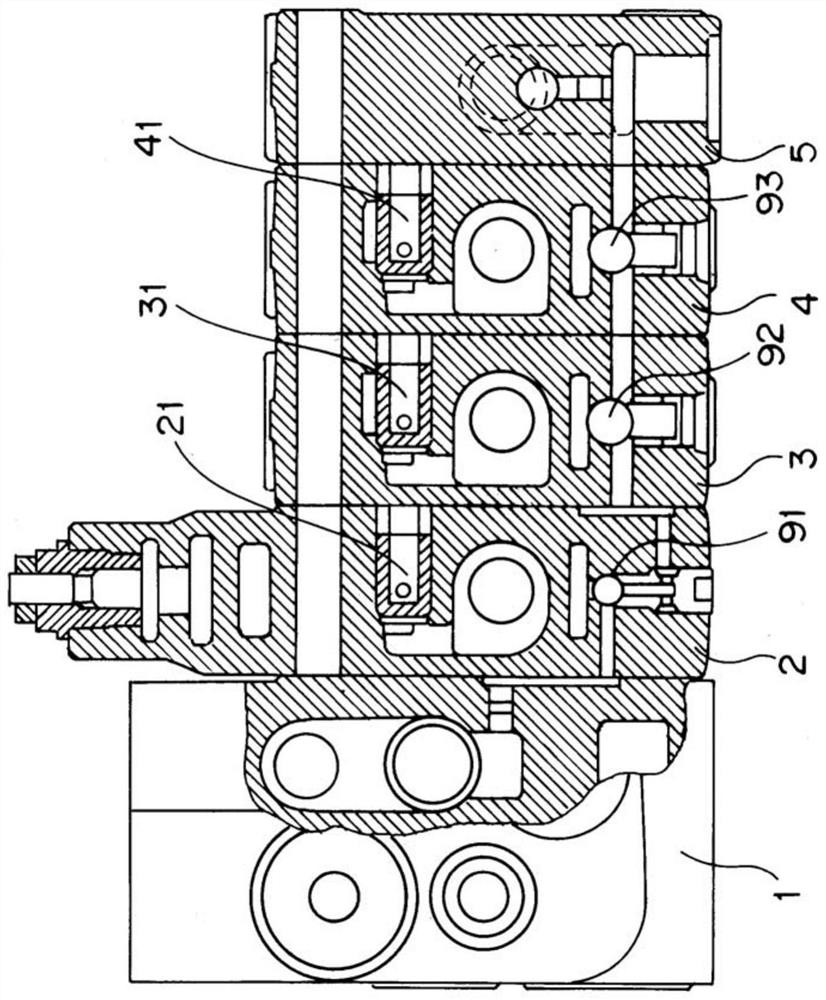

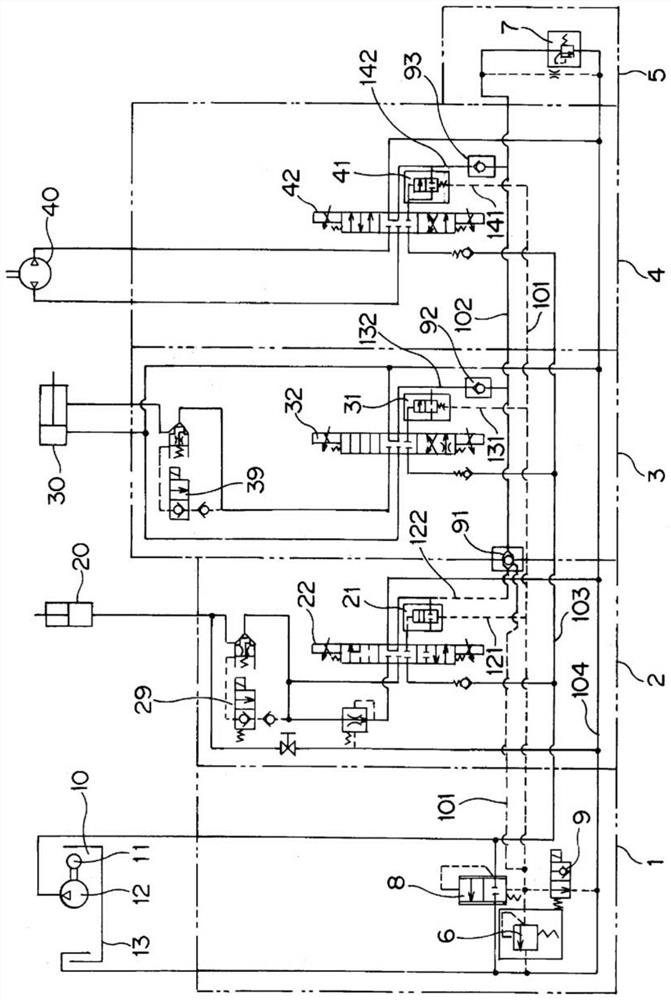

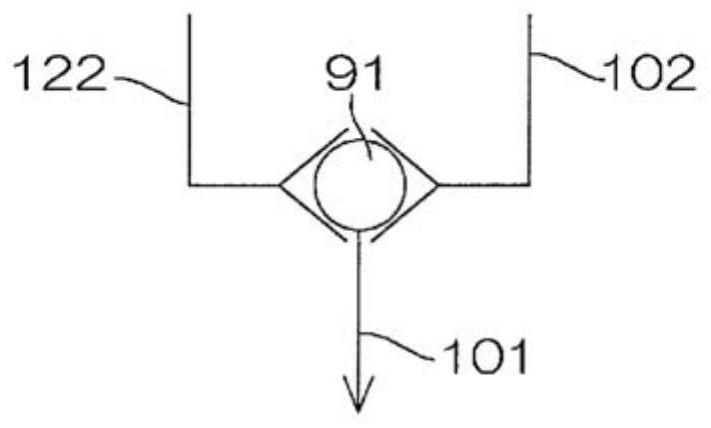

[0025] Hereinafter, embodiments of the present invention will be described based on the drawings. figure 1 It is a schematic longitudinal sectional view of the fluid control device of the present invention. in addition, figure 2 is a hydraulic circuit diagram in the fluid control device of the present invention.

[0026] This fluid control device uses hydraulic oil as the hydraulic fluid and controls the supply of hydraulic oil for each function of the forklift. This fluid control device has the following structure: a front cover 1 for supplying working oil from a hydraulic source 10, a fluid control valve (control valve) 2 for supplying working oil to a lift cylinder 20, and a fluid control valve (control valve) for tilting The cylinder 30 includes a fluid control valve 3 for supplying hydraulic oil, a fluid control valve 4 for supplying hydraulic oil to a rotary drive unit 40 for a rotary attachment, and a rear cover 5 .

[0027] The front cover 1 is connected to a hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com