Food processor with good spill-proof effect

A food processor and anti-spill technology, applied in kitchen utensils, home utensils, applications, etc., can solve problems such as reducing user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

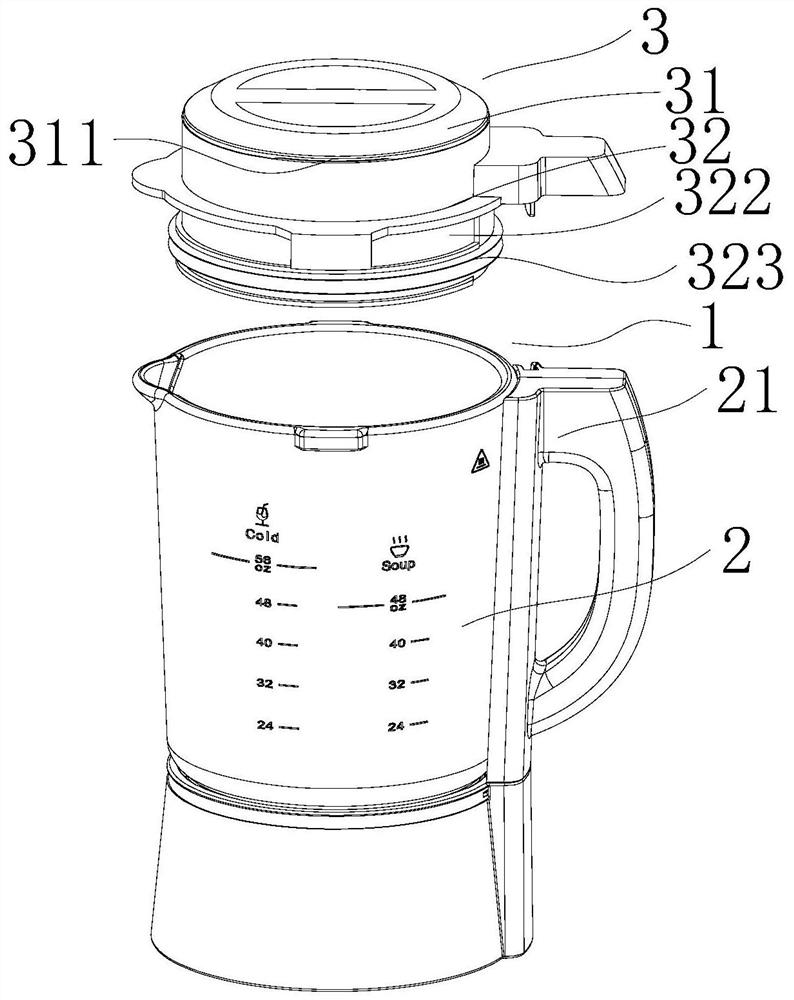

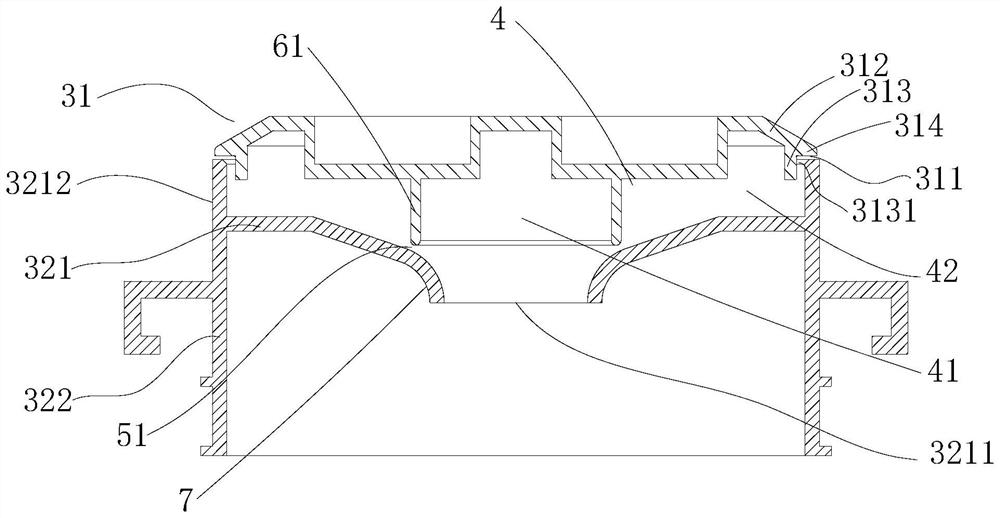

[0034] The structure of the food processing machine of the present embodiment is as Figure 1 to Figure 5 As shown, the food processing machine includes a machine base (not shown) and a stirring cup 1 arranged on the machine base. The stirring cup 1 is detachably connected to the machine base to facilitate cleaning of the stirring cup 1. The machine base is provided with a motor (not shown) and a circuit board (not shown), the stirring cup 1 includes a cup body 2 and a cup cover 3, a handle 21 is provided on one side of the cup body 2, and a crushing knife (not shown) is arranged in the cup body 2 , the upper end of the motor shaft of the motor passes through the machine base and is connected to the lower connector, and the lower end of the cutter shaft of the crushing knife is connected to the upper connector. , so that the motor can drive the pulverizer to rotate in the cup body 2 to pulverize food.

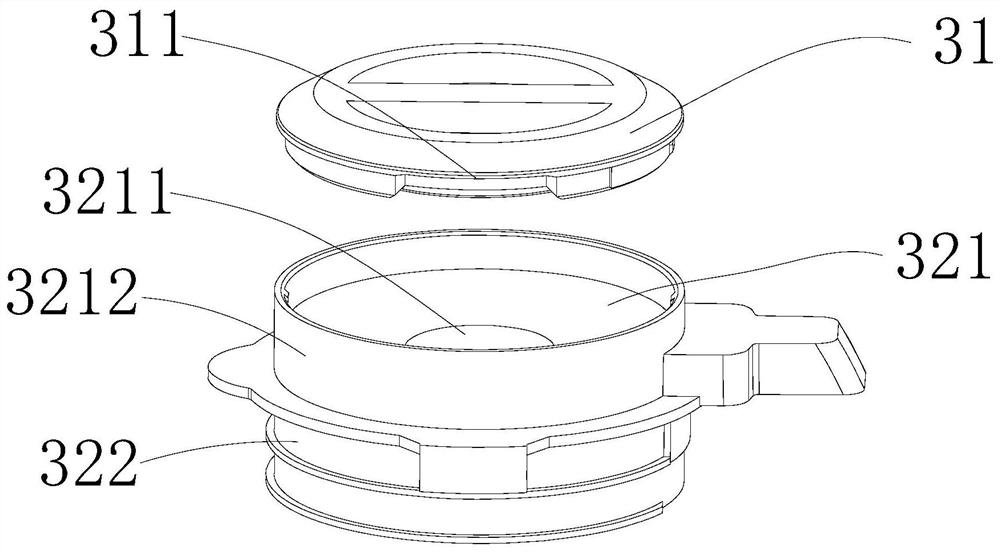

[0035] The cup cover 3 includes an upper cover 31 and a lower cover 32, t...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that there is also an overflow prevention piece, combined with Image 6 and Figure 7 As shown, the lower part of the cup body 2 in this embodiment is provided with a heating body, the heating body is a heating plate with a heating tube, the heating plate is located at the bottom of the cup body 2, and the heating body can heat the food in the cup body 2, The food processing machine of this embodiment can make hot drinks, and when the food is heated and stewed, the liquid boils to generate a lot of foam, so overflow prevention is more important, so this embodiment is also provided with an anti-overflow member 81, which is arranged on the lower cover 32 Above, the setting of the anti-overflow member 81 further improves the anti-overflow effect, and the anti-overflow member 81 and the anti-overflow cavity 4 form a double anti-overflow.

[0054] In this embodiment, the anti-overflow member 81 is arranged verticall...

Embodiment 3

[0061] The difference between the present embodiment and the second embodiment is that the setting positions of the anti-overflow parts are also different. Figure 8 and Figure 9 As shown, the anti-overflow part 81 of the present embodiment is arranged on the loam cake 31, and one end of the anti-overflow part 81, that is, the upper end, extends into the loam cake 31 and is electrically connected with the conductive sheet 82, and the other end of the anti-overflow part 81, that is, the lower end, extends toward the upper cover 31. It extends downward and is set through the through hole 3211. In this way, the anti-overflow member 81 is arranged at the axis of the cup body 2. When the liquid is stirred, a V-shaped area will be formed, so it will not touch the anti-overflow member 81, so that when the liquid is stirred The rotation is more stable, which has a positive impact on the stability of the whole machine and the noise generated by the cup.

[0062] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com