Processing device

A processing device and workpiece technology, applied in the direction of working carrier, grinding workpiece support, etc., can solve problems such as prone to failure and complex structure, and achieve the effect of reducing manufacturing cost and failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

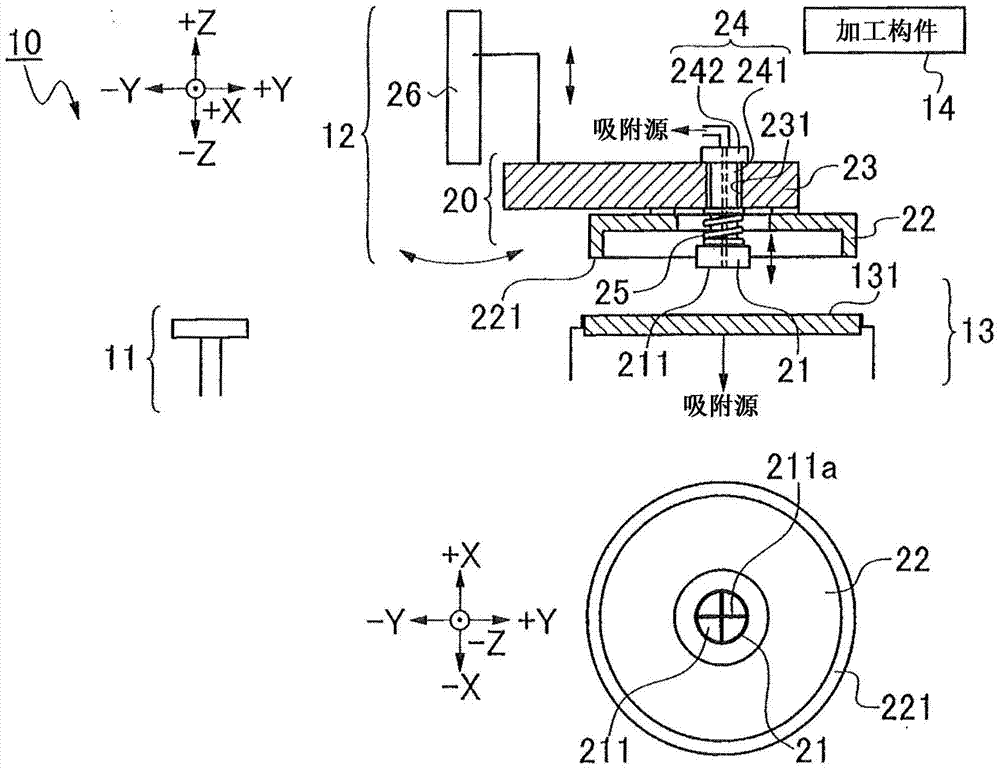

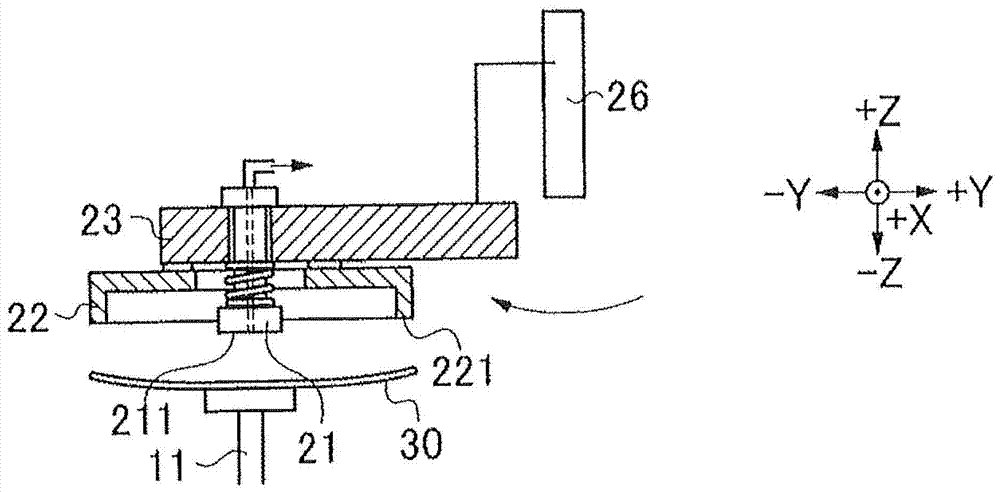

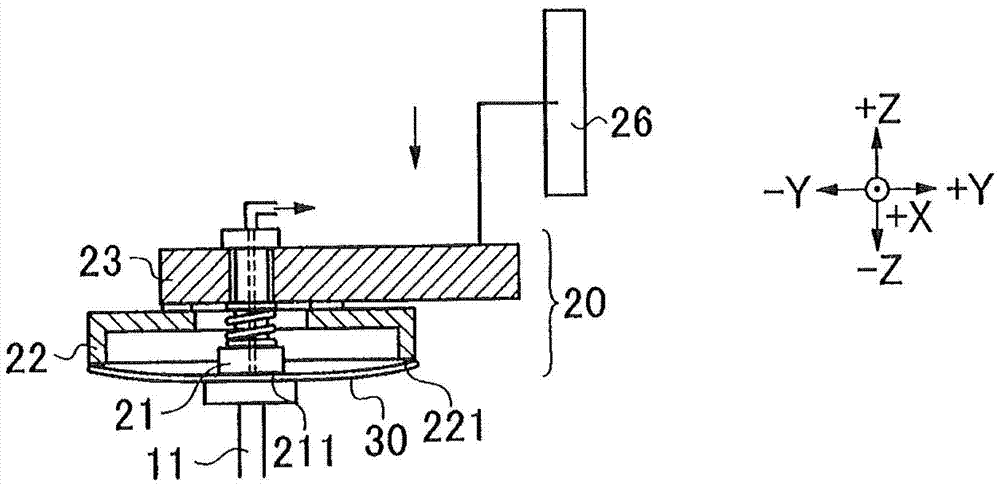

[0019] figure 1 The processing device 10 shown is provided with: a temporary loading table 11, which temporarily mounts disc-shaped workpieces such as wafers; a transport member 12, which transports the workpiece temporarily placed on the temporary loading table 11; The stage 13 holds the workpiece conveyed by the conveying member 12 , and the machining member 14 processes the workpiece held on the chuck table 13 . The processing member 14 has a function of performing processing such as grinding or polishing on a workpiece.

[0020] The chuck table 13 has a holding surface 131 parallel to the XY plane, and absorbs and holds a workpiece placed on the holding surface 131 . If the workpiece is warped, there will be a gap between the workpiece and the holding surface 131 , and therefore, the workpiece may not be adsorbed satisfactorily. For example, when the workpiece is ground thin or heat-treated, the workpiece may warp. In order to reliably hold such a workpiece, it is neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com