Automated welding system for interchangeable welding heads

A technology of automatic welding and welding head, used in welding equipment, welding equipment, auxiliary welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

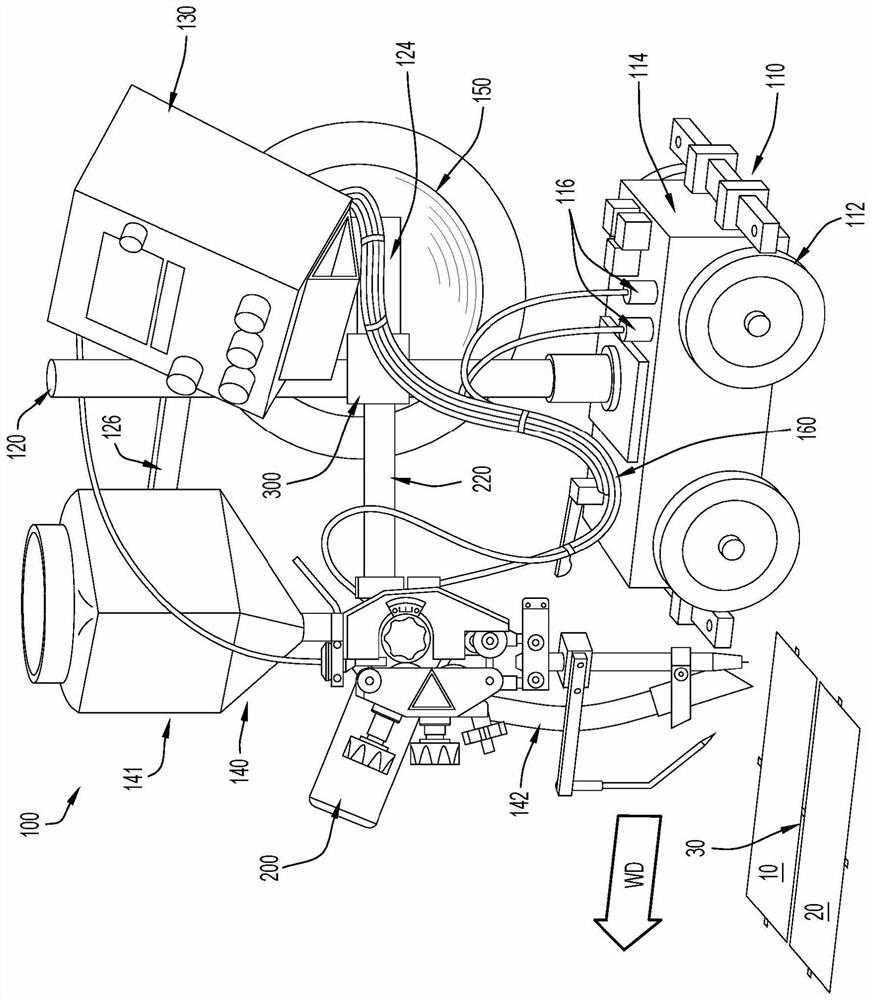

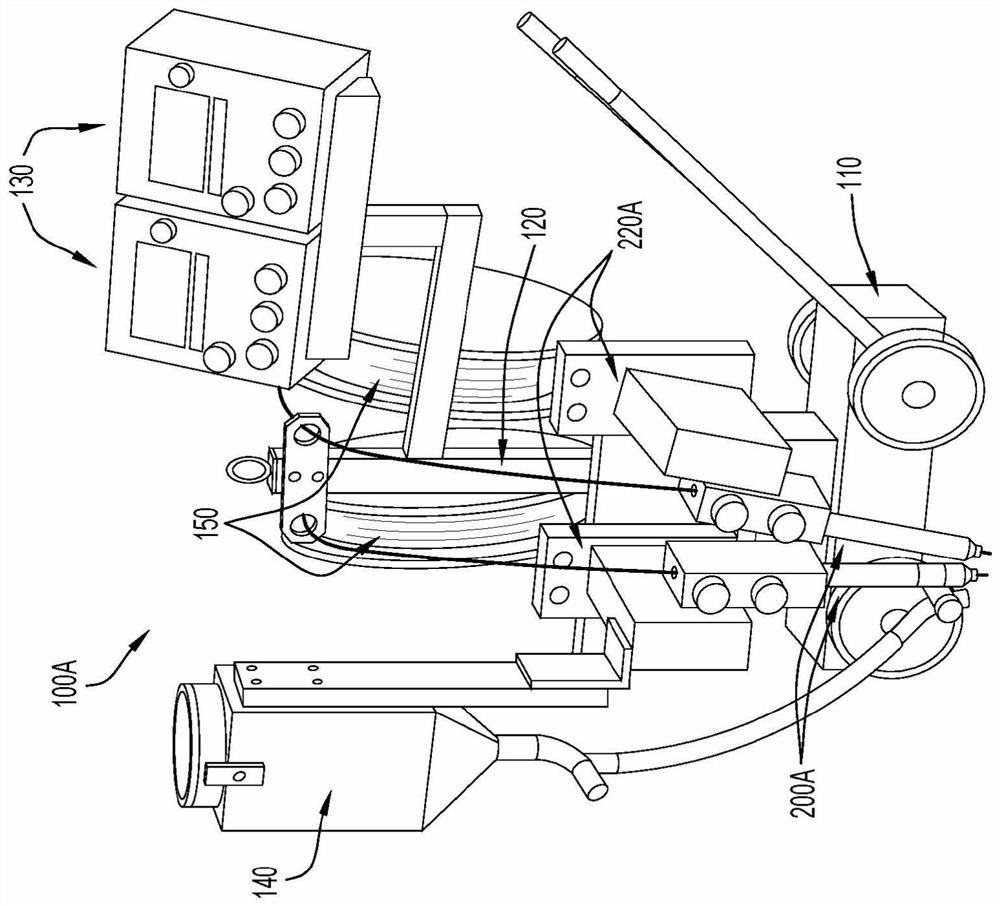

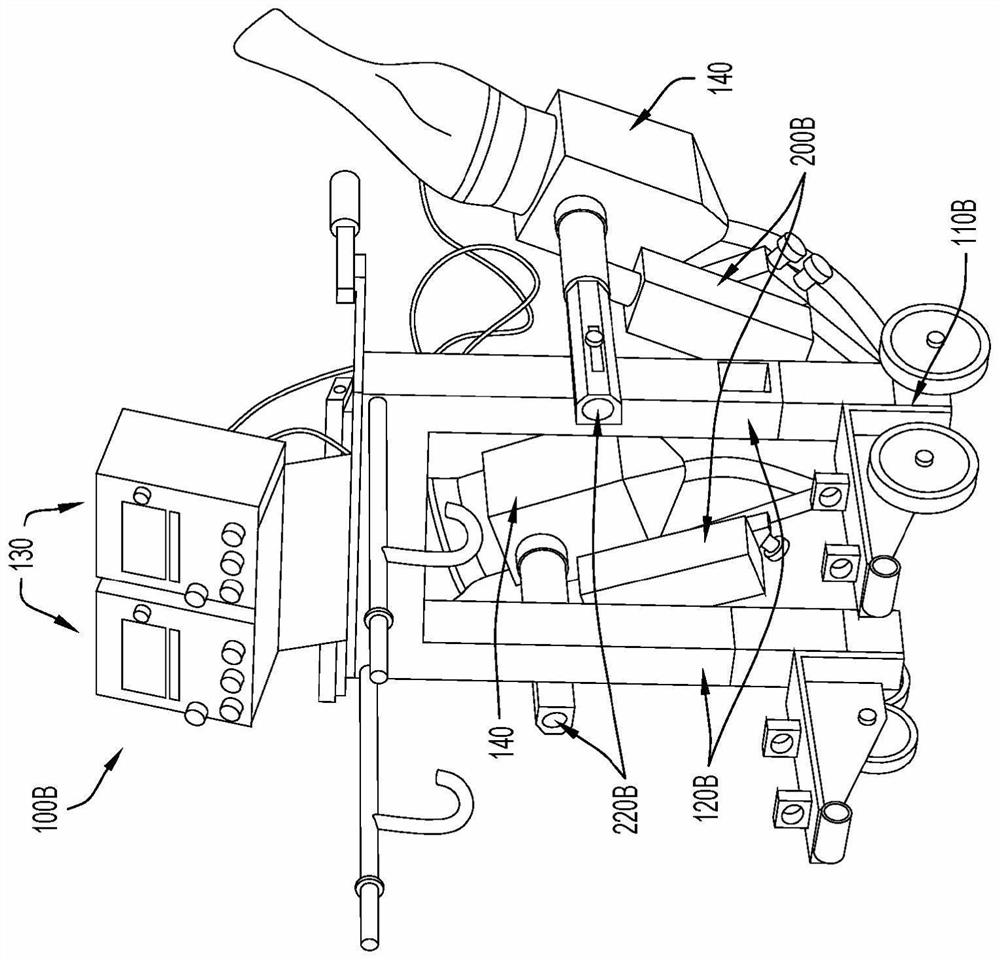

[0028]In general, this paper proposes a welding system capable of receiving and recognizing interchangeable welding tips. When an interchangeable welding head is identified, the system automatically configures itself to support welding operations with the identified welding head. That is, once one of the welding heads is electrically connected to a controller included on the welding device (e.g., tractor or column and boom), the controller can The cable associated with the welding head may have an identification resistor having a unique resistance value) to identify the welding head and configure features (e.g., activate or deactivate components such as the flux subsystem) and / or welding parameters accordingly (For example, limit the range of wire feed speed). Thus, an end user can use a single automation system for multiple types of welding operations, and the end user can quickly and easily switch between these welding operations. For example, an end user (i.e. operator) c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com